Top 10 Applications of FKM Terpolymer: Unlocking Its Versatility and Benefits

Table of Contents

- Applications of FKM Terpolymer in Automotive Seals and Gaskets

- Role of FKM Terpolymer in Chemical Processing Equipment

- Utilization of FKM Terpolymer for Enhanced Fuel and Oil Resistance

- Integration of FKM Terpolymer in Aerospace Components

- Benefits of FKM Terpolymer in Electrical Insulation Applications

- FKM Terpolymer's Impact on Medical Device Manufacturing

- Exploring the Versatility and Applications of General Purpose Fluoroelastomer Base Polymer in Modern Industries

- FAQS

- Conclusion

- Related Posts

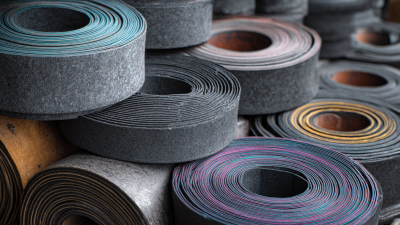

When it comes to cutting-edge materials, FKM Terpolymer really stands out as a top pick. It’s incredibly versatile and brings a bunch of benefits to different industries. As companies are always on the lookout for high-performance materials that can handle extreme conditions, the importance of FKM Terpolymer can’t be overstated. Thanks to its impressive heat resistance, chemical durability, and tough mechanical properties, it’s become the go-to solution for automotive, aerospace, oil and gas, and several other sectors.

Sichuan Fudi New Energy Co., Ltd., started back in 1998, and they've really made a name for themselves in this innovative space. They've been specializing in manufacturing and selling fluoroelastomers and other fluorinated rubber materials for over 20 years now. They offer top-quality FKM terpolymer products—like fluoroelastomer base polymers and FKM compounds—that meet a wide range of needs. Their goal is to help clients unlock the full potential of this amazing material.

In this article, we’re going to take a closer look at the top 10 ways FKM Terpolymer is used. You'll see just how versatile it is and the many advantages it offers across different industries.

Applications of FKM Terpolymer in Automotive Seals and Gaskets

FKM terpolymer, known for its exceptional performance in extreme conditions, has become a vital material in the automotive industry, particularly in the manufacturing of seals and gaskets. Its outstanding chemical resistance and thermal stability allow for reliable performance in demanding environments. As vehicles increasingly incorporate advanced technologies, including electric and hybrid systems, the demand for high-performance materials like FKM terpolymer continues to rise.

FKM terpolymer, known for its exceptional performance in extreme conditions, has become a vital material in the automotive industry, particularly in the manufacturing of seals and gaskets. Its outstanding chemical resistance and thermal stability allow for reliable performance in demanding environments. As vehicles increasingly incorporate advanced technologies, including electric and hybrid systems, the demand for high-performance materials like FKM terpolymer continues to rise.

Tips: When selecting a terpolymer for automotive applications, consider factors such as temperature ranges, exposure to aggressive fluids, and mechanical properties. It's essential to consult with suppliers who specialize in fluorinated rubber materials to ensure you choose the right formulation for your specific needs.

In the context of the growing rubber and elastomer repair market, the versatility of FKM terpolymer positions it as an ideal candidate for various applications. The market for gaskets, especially those incorporating advanced materials like FKM, is expected to expand significantly. Furthermore, as more industries recognize the importance of durability and reliability, the shift towards fluorinated elastomers for sealing solutions is likely to continue. This aligns perfectly with the long-standing expertise of Sichuan Fudi New Energy Co., Ltd., which has been a leader in the production and marketing of fluoroelastomer products for over two decades.

Role of FKM Terpolymer in Chemical Processing Equipment

FKM terpolymer, known for its exceptional resistance to heat, chemicals, and weathering, plays a crucial role in the field of chemical processing equipment. Its unique properties allow it to maintain integrity and performance under extreme conditions, making it ideal for seals, gaskets, and O-rings that are essential in various industrial applications. In sectors such as oil and gas, pharmaceuticals, and food processing, FKM terpolymer contributes significantly to the reliability and safety of equipment by preventing leaks and ensuring optimal operation.

Recent advancements in processing technologies further highlight the versatility of FKM terpolymer. For instance, the increasing demand for efficient treatment systems, such as those for wastewater and industrial applications, is driving innovation in material science. FKM terpolymer can enhance the durability and longevity of processing equipment, thereby reducing maintenance costs and downtime. As industries evolve and stricter regulations emerge, the deployment of FKM terpolymer will likely expand, offering enhanced performance and sustainability in chemical processing environments.

Utilization of FKM Terpolymer for Enhanced Fuel and Oil Resistance

FKM terpolymer, known for its exceptional resistance to fuel and oils, is transforming the landscape of various industries. This synthetic rubber, mainly composed of fluorine, offers enhanced durability against aggressive chemicals and high temperatures, making it a preferred choice in automotive and aerospace applications. The terpolymer's remarkable stability ensures that components made from it retain their integrity, even in challenging environments, thus reducing the frequency of part replacements and downtime.

Furthermore, the versatility of FKM terpolymer allows for innovative designs in sealing technologies, o-rings, and gaskets. Its ability to withstand not only fuels but also various oils expands its applicability in hydraulic systems and machinery, where leak prevention and performance reliability are crucial. As technologies advance and industries seek more efficient materials, the adoption of FKM terpolymer continues to grow, enhancing operational efficiency while minimizing environmental impact.

Top 10 Applications of FKM Terpolymer: Unlocking Its Versatility and Benefits

Integration of FKM Terpolymer in Aerospace Components

The aerospace industry requires materials that can withstand extreme conditions, and FKM terpolymer has emerged as a leading choice for various aerospace components. With its exceptional chemical resistance, thermal stability, and mechanical properties, FKM terpolymer is ideal for sealing applications, fuel systems, and other critical components that operate under high pressure and temperature. Its adaptability ensures reliable performance, making it a preferred material in both commercial and military aerospace applications.

Sichuan Fudi New Energy Co., Ltd., with over 20 years of expertise in producing fluoroelastomers, plays a pivotal role in supplying high-quality FKM compounds tailored for the aerospace sector. The company's dedication to innovation and quality ensures that their products meet the rigorous demands of aerospace standards. By harnessing the versatility of FKM terpolymer, Sichuan Fudi not only enhances the performance of aerospace components but also contributes to the safety and efficiency of flight operations worldwide.

Top 10 Applications of FKM Terpolymer: Unlocking Its Versatility and Benefits - Integration of FKM Terpolymer in Aerospace Components

| Application Area | Description | Key Benefits | Temperature Resistance (°C) | Chemical Resistance |

|---|---|---|---|---|

| O-Rings | Used in sealing applications within aircraft systems. | Durability and excellent sealing performance. | -25 to 200 | Resistant to fuels, oils, and lubricants. |

| Fuel Hoses | Transports fuel in various aircraft types. | Long-lasting and effective against fuel permeation. | -30 to 150 | Highly resistant to avionic fuels. |

| Gaskets | Provide sealing between components in aerospace engines. | Excellent sealing capabilities under pressure. | -20 to 220 | Resistant to acids and petroleum-based products. |

| Diaphragms | Used in control systems for precision regulation. | High flexibility and response rate. | -40 to 175 | Good chemical stability against various media. |

| Seals for Actuators | Ensure proper operation of actuator mechanisms. | Prevents hydraulic fluid leakage and enhances performance. | -30 to 200 | Resistant to a wide range of fluids. |

| Vibration Dampers | Absorb shocks and vibrations in sensitive systems. | Improves component longevity and performance stability. | -40 to 180 | Excellent resilience to environmental factors. |

| Flame Barriers | Protect systems from fire and high temperatures. | Enhances safety and compliance with regulations. | Up to 300 | Superior performance in extreme environments. |

| Connector Seals | Maintain integrity of electrical connectors. | Protects against moisture and debris ingress. | -50 to 150 | Resistant to environmental degradation. |

| Surface Coatings | Protect surfaces from abrasion and chemicals. | Extends lifespan of components while reducing wear. | -40 to 150 | High resistance to solvents and fuels. |

Benefits of FKM Terpolymer in Electrical Insulation Applications

FKM terpolymer has emerged as a game-changer in the field of electrical insulation, offering numerous advantages that enhance the performance and reliability of electrical components. According to a report by Allied Market Research, the global market for electrical insulation materials is projected to reach $77.7 billion by 2027, driven by increasing demand for durable and efficient insulation solutions. FKM terpolymer, with its exceptional thermal stability and chemical resistance, is well-positioned to meet the stringent requirements of this growing market.

One of the notable benefits of FKM terpolymer in electrical insulation applications is its superior electrical resistivity, which is crucial for preventing current leakage. A study published in the Journal of Materials Science highlights that FKM terpolymer exhibits an electrical resistivity exceeding 10^16 ohm-cm at room temperature, making it ideal for use in high-voltage environments. Furthermore, its ability to withstand extreme temperatures, ranging from -26°C to 204°C, allows it to maintain its insulating properties in harsh operating conditions. This resilience not only enhances the longevity of electrical equipment but also reduces maintenance costs significantly, reinforcing FKM's status as a preferred material in the electrical industry.

FKM Terpolymer's Impact on Medical Device Manufacturing

FKM terpolymer, a type of fluoropolymer, is making significant strides in the medical device manufacturing industry due to its unique properties. Known for its exceptional heat resistance, chemical stability, and fuel resistance, FKM terpolymer is an ideal material for various medical applications, including seals, gaskets, and tubing. Its versatility allows manufacturers to create devices that can withstand the rigors of sterilization and harsh chemical environments, which are essential in hospitals and clinics.

As the demand for reliable and durable medical devices continues to grow, the market for fluoropolymers like FKM terpolymer is expanding. The global market size for fluorinated elastomers was valued at approximately $13.56 billion in 2019 and is expected to reach around $17.94 billion by 2027, reflecting a compound annual growth rate of 3.7%. This growth is driven by the increasing adoption of advanced medical technologies and stringent regulatory requirements, emphasizing the need for high-performance materials that can enhance device longevity and safety in critical healthcare settings.

Exploring the Versatility and Applications of General Purpose Fluoroelastomer Base Polymer in Modern Industries

Fluoroelastomers have established themselves as a critical material in various industries, thanks to their extraordinary resistance to heat, chemicals, and deformation. The versatility of General Purpose Fluoroelastomer Base Polymers is epitomized by products like FD 26 and FD 246 grades. The FD 26 grade is a copolymer of vinylidene fluoride (VDF) and hexafluoropropylene (HFP), which is ideal for general sealing applications. Its unique formulation allows it to withstand a range of harsh environments, making it suitable for automotive and aerospace applications where reliability and durability are paramount.

On the other hand, the FD 246 grade presents a more advanced solution with its terpolymer composition of VDF, HFP, and tetrafluoroethylene (TFE). This increased fluorine content translates to superior performance in extreme conditions, including high temperatures and aggressive chemicals. According to recent industry reports, the global demand for high-performance elastomers, including fluorinated varieties, is projected to grow by 5.3% annually, driven by advancements in manufacturing processes and an increase in industrial applications.

Both grades possess a shelf life of two years, ensuring their readiness when needed. Their proven capabilities underline the value of incorporating General Purpose Fluoroelastomers into modern industrial applications. For companies seeking reliable sealing solutions, both FD 26 and FD 246 offer unparalleled performance, and potential customers can request free stock samples to evaluate their suitability.

FAQS

: FKM terpolymer is a specialized material known for its exceptional performance in extreme conditions, making it crucial for seals and gaskets in vehicles. Its chemical resistance and thermal stability enable reliable performance, especially as advanced vehicle technologies become more prevalent.

When selecting a terpolymer, factors such as temperature ranges, exposure to aggressive fluids, and mechanical properties should be considered. Consulting suppliers who specialize in fluorinated rubber materials is also essential to ensure the right formulation is chosen.

The versatility of FKM terpolymer positions it as an ideal candidate for various applications, and the market for gaskets incorporating advanced materials like FKM is expected to grow significantly due to the increasing recognition of durability and reliability.

Industries such as oil and gas, pharmaceuticals, and food processing benefit significantly from FKM terpolymer due to its heat and chemical resistance, which helps maintain equipment integrity, prevent leaks, and ensure optimal operation.

FKM terpolymer enhances the durability and longevity of processing equipment, which can lead to reduced maintenance costs and downtime, especially in wastewater and industrial treatment systems.

FKM terpolymer is suitable for aerospace components due to its exceptional chemical resistance, thermal stability, and mechanical properties, making it ideal for sealing applications and critical components that operate under high pressure and temperature.

Sichuan Fudi New Energy Co., Ltd. has over 20 years of expertise in producing fluoroelastomers and plays a crucial role in supplying high-quality FKM compounds tailored for the aerospace sector, ensuring that products meet rigorous aerospace standards.

By enhancing the performance of aerospace components, FKM terpolymer contributes to the safety and efficiency of flight operations, which is vital for both commercial and military applications.

The increasing demand for high-performance materials due to advancements in technology, as well as stricter industry regulations, are driving the demand for FKM terpolymer across industries such as automotive, chemical processing, and aerospace.

Conclusion

FKM Terpolymer is a highly versatile material that plays a critical role across various industries. Its applications range from automotive seals and gaskets to chemical processing equipment, where it provides enhanced durability and resistance to harsh environments. In the automotive sector, FKM Terpolymer ensures reliable sealing, while in chemical processing, it withstands aggressive solvents and temperatures. Additionally, its exceptional fuel and oil resistance makes it indispensable for components in aerospace and automotive industries.

Moreover, FKM Terpolymer benefits electrical insulation applications, offering superior performance in high-voltage environments. Its significance extends to medical device manufacturing, where safety and reliability are paramount. With over 20 years of expertise, Sichuan Fudi New Energy Co., Ltd. is dedicated to producing high-quality FKM Terpolymer and other fluorinated rubber materials, addressing the growing demand for reliable and efficient solutions in diverse applications.

Related Posts

-

Exploring Industry Trends for Viton Hose at the 2025 China 138th Canton Fair

-

How to Choose the Right Viton Sheet for Your Industrial Needs

-

7 Reasons Why FKM Is Viton the Best Choice for Your Industrial Needs

-

What is Oring De Viton Parker and How It Enhances Sealing Performance in Various Industries

-

Ultimate Guide to Understanding the Benefits of Fkm Rubber in Industrial Applications

-

Exploring the Versatile Applications of Fluoroelastomer Rubber Sheets in Modern Industry

Blog Tags:

Eleanor

-

Phone

-

E-mail

-

Whatsapp

-

Top