Exploring the Benefits of Aflas Material: A Breakthrough in Industrial Applications

Table of Contents

- Benefits of Aflas Material in High-Temperature Applications for the Aerospace Industry

- Durability and Chemical Resistance of Aflas Material in Chemical Processing Industries

- Cost Savings and Efficiency Gains from Aflas Material in Manufacturing Processes

- Aflas Material vs. Traditional Rubber: A Performance Comparison in Industrial Settings

- Sustainability Aspects of Aflas Material in Green Manufacturing Initiatives

- FAQS

- Conclusion

- Related Posts

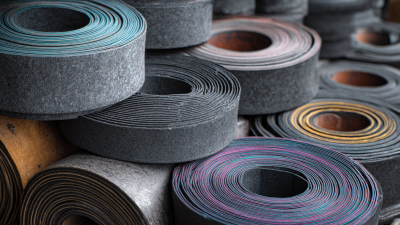

The industrial landscape is constantly changing, shaped by the growing need for high-performance materials that can handle really tough conditions. One standout in this space is Aflas Material — a key fluoroelastomer known for its impressive resistance to heat, chemicals, and oxidative damage. I recently came across a market report that estimates the global fluoroelastomer market will hit around USD 3.55 billion by 2027. This growth is largely fueled by rising demand across sectors like automotive, aerospace, and oil and gas. Companies like Sichuan Fudi New Energy Co., Ltd., which has been around since 1998, have quite a bit of experience under their belts when it comes to producing and marketing these kinds of materials. They’re known for making products like FKM compounds and curing agents, and their expertise really helps meet the increasing need for materials that are both reliable and long-lasting. All of this means better performance and durability in a bunch of different applications — pretty important stuff these days, I’d say.

Benefits of Aflas Material in High-Temperature Applications for the Aerospace Industry

You know, Aflas—a type of perfluoroelastomer—is really shaking things up when it comes to high-temperature stuff, especially in aerospace. Its special mix allows it to handle crazy hot temps, often over 260°C (that’s around 500°F), which makes it perfect for things like seals and gaskets on planes. I recently came across a report from the Freedonia Group, and it said the demand for these advanced sealing materials is set to grow by about 8.1% each year. That’s mainly because we’re building more aircraft and also because people want more reliable parts that can handle the tough conditions up in the sky.

And get this—Aflas isn’t just heat-resistant; it’s also pretty tough against chemicals. It beats out regular elastomers when it comes to resisting fuels and oils that are pretty aggressive in aviation. There’s even a study in the International Journal of Aerospace Engineering mentioning that using Aflas seals in jet engines can cut down maintenance by roughly a quarter—that’s huge savings for airlines and manufacturers. As aerospace tech keeps evolving, I think we’ll see more of Aflas being used to make engines more reliable and efficient. It’s all about cutting costs and keeping things safe up there, you know?

Durability and Chemical Resistance of Aflas Material in Chemical Processing Industries

You know, Aflas is really shaking things up in the world of industrial stuff, especially in chemical processing. It’s like this tough, durably built material that can handle the roughest environments where most other materials just give up. What’s pretty cool is that Aflas isn’t just good at dealing with super hot or cold temps—it also fights off nasty chemicals like acids, bases, and solvents like a champ. Because of that, it’s perfect for things like seals, gaskets, and liners in chemical plants where stuff gets pretty intense.

One of the biggest perks of Aflas is how resistant it is to chemicals. That means it lasts longer and keeps working reliably, even in tough conditions. Unlike typical rubbery materials, Aflas keeps its shape and strength even when exposed to corrosive substances. This helps reduce the chances of machinery breaking down or having to shut down unexpectedly. Plus, it makes the whole operation safer—protecting workers and the environment too. As industries focus more on performance and being eco-friendly, Aflas really stands out as a go-to material—combining toughness and peace of mind like no other.

Cost Savings and Efficiency Gains from Aflas Material in Manufacturing Processes

Switching over to Aflas material in manufacturing isn't just a game-changer in terms of cost savings and boosting efficiency; it's also perfectly in sync with how AI is becoming a staple in industrial settings these days. Aflas is renowned for its incredible resistance to heat, chemicals, and oils—think of it as a real breakthrough, especially in industries where durability isn’t optional. This kind of development really matters now, as companies look for smarter ways to run their operations more smoothly amidst strict quality demands and rising costs.

As more manufacturers start to bring AI tools into the mix, combining Aflas with cutting-edge manufacturing techniques can take productivity to the next level. For example, AI-powered predictive maintenance can help figure out the best conditions for using Aflas in different processes, which means less downtime and less waste. Plus, Aflas’ versatility fits nicely with innovative design methods like generative design—opening up new possibilities for developing high-performing products. Companies like Sichuan Fudi New Energy Co., Ltd., with over 20 years dealing with fluorinated rubber materials, are in a great spot to really make the most of these advancements, leading to more efficient and cost-effective manufacturing all around.

Aflas Material vs. Traditional Rubber: A Performance Comparison in Industrial Settings

Have you heard about Aflas material? It's a type of elastomer made from poly(alkenylene ether), and honestly, it's been gaining a lot of attention as a real contender to traditional rubber in various industrial settings. When you compare it based on key performance factors—like heat resistance, chemical stability, and mechanical strength—Aflas just tends to come out on top quite consistently. For example, studies show that it can handle temperatures up to around 200°C and resist harsh chemicals such as acids, bases, and fuels. That kinda toughness makes it perfect for demanding industries like automotive and aerospace.

At Sichuan Fudi New Energy Co., Ltd, we've got over 20 years of experience working with fluoroelastomers and fluorinated rubber materials. Our products are designed to match the impressive qualities of Aflas, helping improve the durability and longevity of various industrial components. Market trends are pointing toward even more demand—it's predicted that the need for high-performance elastomers like Aflas will grow at a CAGR of around 6.5% through 2025. Basically, more industries are recognizing how crucial these materials are for handling tough conditions.

**A little tip:** When you're picking materials for your projects, it’s a good idea to think about the environmental factors they'll face. Aflas's special properties can really boost your product’s performance and reliability. And don’t forget—doing a proper cost-benefit analysis can save you a lot of headaches, helping you get the best bang for your buck while making sure everything runs smoothly.

Performance Comparison of Aflas Material vs. Traditional Rubber in Industrial Applications

This chart compares the performance of Aflas material against traditional rubber in key industrial application metrics. Aflas material demonstrates superior tensile strength, elongation at break, heat resistance, and chemical resistance, highlighting its advantages for demanding industrial environments.

Sustainability Aspects of Aflas Material in Green Manufacturing Initiatives

So, Aflas material—it's been getting a lot of buzz lately, mainly because of its incredible resistance to chemicals and its ability to handle high temperatures. People are really starting to see it as a game-changer in the push toward greener manufacturing. What’s cool is that its special fluoropolymer structure doesn’t just boost how long your products last; it also helps cut down waste and save energy during production. I came across this recent report from MarketsandMarkets, and it’s pretty eye-opening—global green manufacturing is set to jump from about 10.8 billion dollars in 2021 all the way up to over 30 billion by 2026. That’s a huge shift towards more eco-friendly materials and methods, which is super encouraging. And honestly, Aflas fits right into that trend. It offers manufacturers a solid, sustainable option for tons of industrial uses.

But it’s not just about waste reduction—Aflas can also make a real difference when it comes to energy efficiency. Traditional materials often eat up a lot of energy over their lifecycle, which adds to carbon emissions—and nobody’s really lining up for that, right? Aflas, on the other hand, can handle extreme conditions, meaning fewer replacements and less maintenance needed. According to the EPA, switching to Aflas can cut greenhouse gases by up to 30%. Not only does that help companies meet regulatory standards, but it also shows they’re serious about being eco-friendly. Plus, it’s good PR—more and more consumers are looking to support businesses that really care about the environment.

Exploring the Benefits of Aflas Material: A Breakthrough in Industrial Applications - Sustainability Aspects of Aflas Material in Green Manufacturing Initiatives

| Industry Sector | Application | Sustainability Benefit | Key Property | Impact on Green Manufacturing |

|---|---|---|---|---|

| Automotive | Sealants and Gaskets | Reduced emissions through long-lasting components | Excellent chemical resistance | Lower lifecycle environmental impact |

| Aerospace | O-rings and Seals | Enhanced durability and reduced waste | High temperature stability | Improved fuel efficiency |

| Chemical Processing | Piping and Valves | Minimized product loss and spills | Resistance to aggressive chemicals | Sustained performance with less waste |

| Electronics | Insulating Materials | Lower energy usage | Electrical insulation properties | Reduced carbon footprint in production |

| Pharmaceuticals | Packing Materials | Sustainable packaging options | Non-reactive with sensitive compounds | Less waste through better protection |

FAQS

flas material and what are its primary benefits in manufacturing?

Aflas material consistently outperforms traditional rubber in key areas such as heat resistance (up to 200°C), chemical stability, and mechanical properties, making it particularly suitable for demanding environments like automotive and aerospace industries.

AI technologies can optimize the utilization of Aflas material through predictive maintenance, which identifies ideal production conditions, reduces downtime, and minimizes waste, thereby enhancing operational efficiency.

Sichuan Fudi New Energy Co., Ltd. has over 20 years of experience in fluorinated rubber materials and offers high-performance Aflas products designed to perform exceptionally in demanding industrial scenarios.

The demand for high-performance elastomers, including Aflas, is expected to grow at a compound annual growth rate (CAGR) of 6.5% through 2025, as industries shift towards materials that can endure rigorous operational conditions.

When choosing materials, it is important to consider the specific environmental challenges they will face. Aflas material’s unique properties can greatly enhance product performance and reliability, so a thorough cost-benefit analysis is advised for optimizing material selection.

Aflas material is particularly beneficial in the automotive and aerospace industries due to its heat resistance and chemical stability, which are essential for high-performance applications.

Yes, Aflas material's adaptability complements generative design approaches, which allows for innovative product developments while still maintaining high performance levels.

The incorporation of Aflas material can help companies optimize their operations and reduce production costs while adhering to stringent quality standards by increasing the durability and lifespan of components.

Conclusion

Aflas Material is really making waves in industrial settings, especially in high-temperature environments like the aerospace sector where it’s vital to have materials that can handle extreme heat without breaking a sweat. One of the coolest things about it is how tough and resistant to chemicals it is—perfect for various chemical processing industries. Not only does this help cut down on maintenance costs, but it also keeps things running smoothly and efficiently.

When you compare Aflas to regular rubber, the differences are pretty clear. It just performs better in so many ways, which means companies can save a good chunk of change during manufacturing. Plus, it’s more eco-friendly, fitting nicely with green manufacturing goals. With over 20 years of experience in producing fluoroelastomers, Sichuan Fudi New Energy Co., Ltd. really knows their stuff. They’re in a great position to help industries needing high-performance materials that can stand up to tough conditions—whether it’s extreme heat, chemicals, or whatever else comes their way.

Related Posts

-

How to Choose the Right Fpm Gasket Material for Your Industrial Applications

-

How to Choose the Right Viton Sheet for Your Industrial Needs

-

Ultimate Guide to Understanding the Benefits of Fkm Rubber in Industrial Applications

-

Optimizing Performance: Innovative Solutions Using FKM Material Properties

-

Exploring Fkm Seal Innovations at the 138th Canton Fair in China 2025

-

Top Strategies for Boosting Efficiency with Material Fkm Viton in Industrial Applications

Blog Tags:

Oliver

-

Phone

-

E-mail

-

Whatsapp

-

Top