Top 5 Benefits of Fkm Rubber Material for Industrial Applications

Table of Contents

- Exploring the Durability of FKM Rubber in Harsh Industrial Environments

- Chemical Resistance Properties of FKM Rubber for Enhanced Performance

- High-Temperature Tolerance: FKM Rubber's Advantage in Industrial Applications

- Reduced Maintenance Costs with FKM Rubber Seals and Gaskets

- Versatility of FKM Rubber Across Multiple Industrial Sectors

- Environmental Impact and Sustainability of FKM Rubber Materials in Industry

- FAQS

- Conclusion

- Related Posts

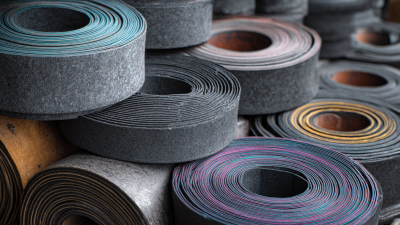

When it comes to industrial stuff, what materials you pick can really make a difference in how well things work and how long they last. One material that’s been getting a lot of buzz lately is FKM rubber — it’s known for its crazy good resistance to chemicals and high temps. I read somewhere (Grand View Research, to be exact) that the global elastomers market, which includes FKM, is expected to hit around USD 50.56 billion by 2025. That just shows how much demand there’s been for cutting-edge materials across different industries.

Dr. John Thompson, a well-known polymer science expert at Rubber Technology Innovations, pointed out that “The versatility and performance of FKM rubber make it a perfect fit for all sorts of things — from car seals to aerospace parts.” That gets the point across that FKM rubber isn’t just reliable but also helps make products safer and more efficient. As industries keep pushing to improve how well everything runs, getting a handle on what FKM rubber can do is more important than ever.

Exploring the Durability of FKM Rubber in Harsh Industrial Environments

FKM rubber, known for its exceptional durability, is increasingly being recognized as a crucial material in harsh industrial environments. Its inherent resistance to extreme temperatures, aggressive chemicals, and ozone exposure makes FKM rubber a preferred choice in sectors such as oil and gas, automotive, and aerospace. The development of advanced formulations, including those infused with graphene nanotubes, promises to enhance these properties even further, thus providing additional protection in the most demanding applications.

As industries grapple with the challenges of maintaining performance while adhering to environmental regulations—such as the potential European ban on PFAS—FKM rubber remains a key player. While replacement alternatives are being explored, they often come with compromises in material integrity and performance. FKM's resilience assures that equipment can operate reliably amidst harsh conditions, making it indispensable in high-stakes environments where failure is not an option. The evolving landscape of rubber coatings underlines the growing demand for materials that can withstand the rigors of modern industrial applications, further solidifying FKM's position at the forefront of technological advancements in material science.

Chemical Resistance Properties of FKM Rubber for Enhanced Performance

FKM rubber, known for its exceptional chemical resistance properties, has emerged as a favored material in various industrial applications. Its robustness against aggressive chemicals significantly enhances performance, making it ideal for harsh environments encountered in the chemical processing and aerospace sectors. Recent advancements have further augmented its potential; for instance, incorporating carbon nanotubes (CNT) and boron nitride (BN) into FKM composites has led to improved mechanical properties and thermal conductivity. This synergistic effect not only enhances the material's vulcanization performance but also boosts its heat stability, catering to industries that require high-performance elastomers.

According to market projections, the rubber coatings market is set to expand dramatically, projected to reach USD 14.54 billion by 2035. This growth is partly driven by innovations in fluororubber, with a pressing demand for materials that can withstand extreme conditions while maintaining durability. Additionally, recent studies indicate that incorporating hydrotalcite-like additives can significantly bolster resistance properties in various rubber types, offering new avenues for developing sustainable and resilient fluororubber materials. With green hydrogen gaining traction as a clean industrial feedstock, the need for reliable, chemically resistant materials remains paramount in supporting this shift towards sustainability in manufacturing processes.

High-Temperature Tolerance: FKM Rubber's Advantage in Industrial Applications

FKM rubber, known for its exceptional high-temperature tolerance, stands out as a superior material for various industrial applications. This remarkable capability allows FKM to perform reliably in environments where other elastomers may fail, making it a preferred choice for industries that face extreme heat and aggressive chemical exposure. The ability to maintain integrity and flexibility at elevated temperatures not only enhances the durability of industrial components but also significantly reduces maintenance costs and downtime.

At Sichuan Fudi New Energy Co., Ltd., we have been at the forefront of producing and marketing fluoroelastomer materials for over two decades. Our expertise in developing FKM and other fluorinated rubber products enables us to meet the specific needs of diverse industrial applications. As industries evolve and demand components that can withstand the rigors of high-temperature environments, our commitment to quality and innovation ensures that our products deliver unbeatable performance and reliability for our clients.

Reduced Maintenance Costs with FKM Rubber Seals and Gaskets

FKM rubber, known for its excellent resistance to extreme temperatures and aggressive chemicals, plays a crucial role in the industrial sector, especially through the use of seals and gaskets.

One of the primary advantages of employing FKM rubber seals and gaskets is the significant reduction in maintenance costs. These components require less frequent replacement compared to conventional materials, which can degrade rapidly in harsh environments.

Moreover, the durability and reliability of FKM rubber contribute to lower downtime in industrial operations. When machinery is not held up by frequent repairs or part replacements, production efficiency is maximized. This not only enhances output but also leads to better resource allocation and savings over time.

By investing in FKM rubber seals and gaskets, businesses can ensure their operations run smoothly, ultimately leading to enhanced profitability and sustainability in the long run.

Versatility of FKM Rubber Across Multiple Industrial Sectors

FKM rubber, known for its exceptional chemical resistance and thermal stability, has found diverse applications across multiple industrial sectors. This versatile material is extensively used in the automotive industry for seals, gaskets, and hoses that must withstand extreme temperatures and aggressive fluids. Its ability to resist degradation from fuels, oils, and chemicals makes FKM the go-to choice for manufacturers striving to enhance durability and reliability in their products.

In addition to automotive uses, FKM rubber is also prominent in the aerospace sector. Components made from FKM exhibit high performance essential for withstanding the harsh conditions encountered during flight. The material's elasticity and resistance to UV rays and ozone further contribute to its suitability in outdoor applications, such as in construction and energy sectors. By leveraging FKM rubber's unique properties, industries can improve the lifespan of their components while ensuring operational efficiency and safety.

Environmental Impact and Sustainability of FKM Rubber Materials in Industry

FKM rubber materials, known for their resilience and chemical resistance, have significant environmental benefits that make them increasingly popular in industrial applications. The versatility of fluoroelastomers allows for extended product lifespans, which directly contributes to sustainability. According to a report by the American Chemistry Council, the longevity of FKM materials can reduce waste by extending the service interval for industrial components. This not only diminishes the frequency of replacements but also minimizes the environmental footprint associated with production and disposal.

Moreover, FKM rubber's ability to withstand extreme temperatures and aggressive chemicals enhances operational efficiency in diverse industries, from automotive to aerospace. This stability reduces the need for frequent maintenance and replacement, further contributing to a decrease in resource consumption. Sichuan Fudi New Energy Co., Ltd., with over 20 years of expertise in producing fluoroelastomers, ensures that their products meet stringent environmental and safety standards, thereby supporting industries in achieving their sustainability goals while maintaining high performance in demanding conditions. As the demand for environmentally responsible materials grows, FKM's role in fostering a greener industrial landscape becomes increasingly critical.

Top 5 Benefits of FKM Rubber Material for Industrial Applications

The chart below illustrates the top five benefits of FKM rubber material in industrial applications, showcasing its environmental impact and sustainability. The values indicate the importance level of each benefit based on industry surveys.

FAQS

: FKM rubber is known for its exceptional chemical resistance properties, which make it a favored material in various industrial applications.

FKM rubber seals and gaskets require less frequent replacement compared to conventional materials, resulting in significant reduction in maintenance costs and lower downtime in industrial operations.

Recent advancements include the incorporation of carbon nanotubes (CNT) and boron nitride (BN), leading to improved mechanical properties, thermal conductivity, and overall performance.

FKM rubber contributes to sustainability by extending the product lifespan, which reduces waste and the environmental footprint associated with production and disposal.

The growing demand is driven by the need for materials that can withstand extreme conditions while maintaining durability, especially in sectors like chemical processing and aerospace.

Its ability to withstand extreme temperatures and aggressive chemicals reduces the need for frequent maintenance and replacements, enhancing operational efficiency across various sectors.

Sichuan Fudi New Energy Co., Ltd. specializes in producing fluoroelastomers that meet stringent environmental and safety standards, aiding industries in achieving sustainability goals.

The rubber coatings market is projected to reach USD 14.54 billion by 2035, driven by innovations in fluororubber and the demand for reliable materials.

Incorporating hydrotalcite-like additives can significantly improve resistance properties in various rubber types, leading to the development of more resilient fluororubber materials.

FKM rubber is beneficial in industries such as automotive and aerospace, where its chemical resistance and thermal stability are critical for performance.

Conclusion

FKM rubber material offers numerous advantages for industrial applications, making it a preferred choice in harsh environments. Its durability ensures longevity even under extreme conditions, while its exceptional chemical resistance enhances performance across various industries. The high-temperature tolerance of FKM rubber means it can withstand intense heat, reducing the risk of failure in critical applications. Furthermore, utilizing FKM rubber seals and gaskets can lead to significant reductions in maintenance costs, offering both economic and operational efficiencies.

Additionally, FKM rubber's versatility allows it to be used across multiple industrial sectors, from automotive to aerospace. As companies increasingly focus on sustainability, the environmental impact of FKM rubber materials is becoming a key consideration, highlighting their role in advancing eco-friendly practices. At Sichuan Fudi New Energy Co., Ltd., with over 20 years of expertise in fluoroelastomer production, we are committed to providing high-quality FKM rubber materials that meet the demands of modern industry.

Related Posts

-

Exploring the Advantages of FKM Rubber: Why It's the Ultimate Choice for Industrial Applications

-

Ultimate Guide to Understanding the Benefits of Fkm Rubber in Industrial Applications

-

Exploring the Future of Fluoroelastomer Polymers at China’s 138th Canton Fair 2025

-

Exploring Fkm Gasket Innovations at the 138th Canton Fair 2025 in China

-

Unlocking the Potential of FKM Rubber: A Deep Dive into Its Applications and Performance Metrics

-

Understanding Fluoroelastomer Cord: The Key to High-Performance Sealing Solutions

Blog Tags:

Charlotte

-

Phone

-

E-mail

-

Whatsapp

-

Top