7 Best Practices for Working with Fluorocarbon Rubber in Industrial Applications

Table of Contents

- Understanding Fluorocarbon Rubber: Properties and Industrial Relevance

- Key Applications of Fluorocarbon Rubber in Industrial Settings

- Essential Safety Practices for Handling Fluorocarbon Rubber

- Maintenance and Storage Tips for Fluorocarbon Rubber Components

- Common Mistakes to Avoid When Working with Fluorocarbon Rubber

- Innovative Manufacturing Techniques for Fluorocarbon Rubber Products

- FAQS

- Conclusion

- Related Posts

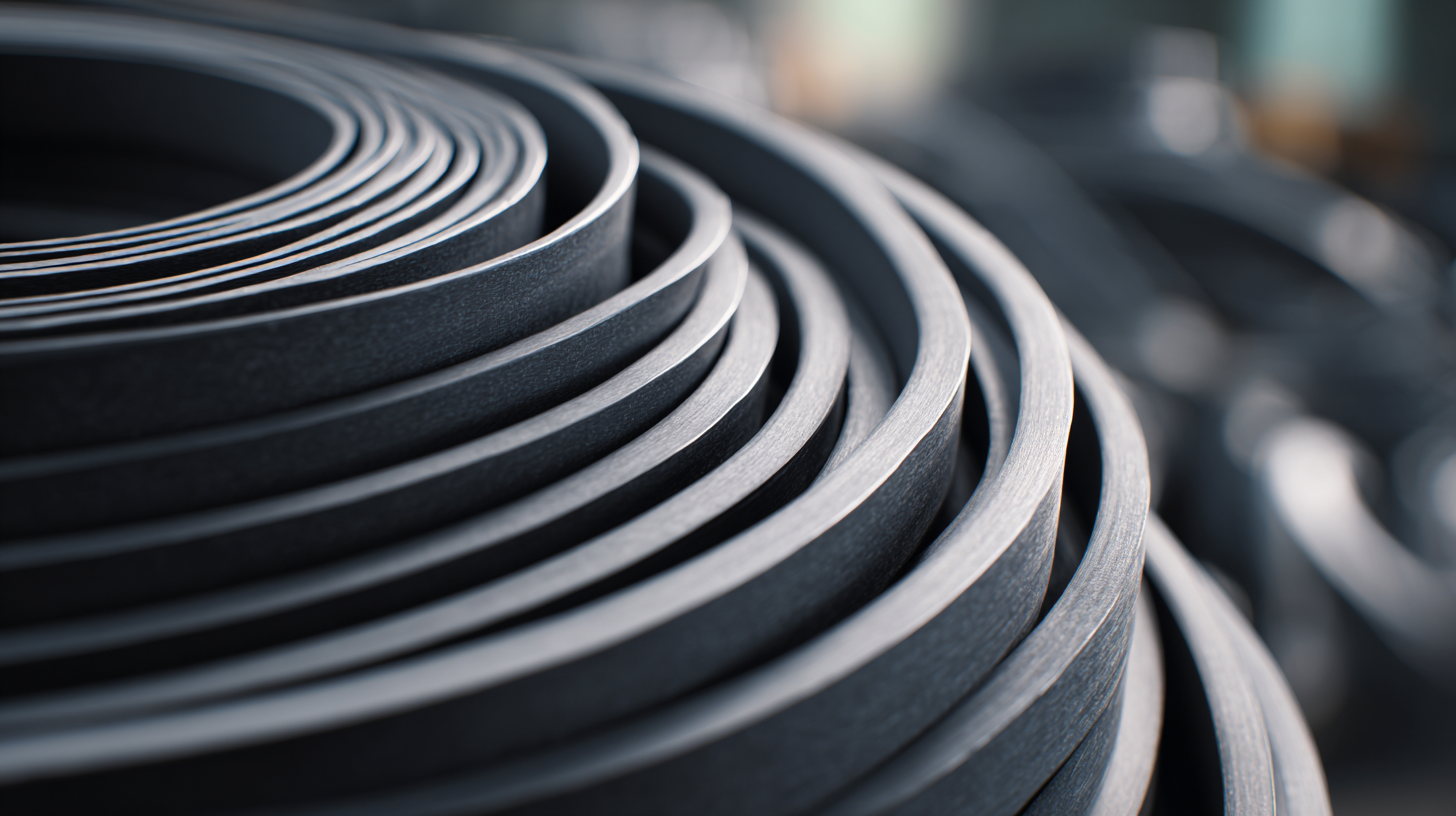

When it comes to industrial applications, Fluorocarbon Rubber has really proven itself as a go-to material, thanks to its outstanding resistance to chemicals, ability to handle high temperatures, and long-lasting durability. As companies look for more reliable and efficient materials, getting the hang of the best practices for working with this special kind of elastomer becomes pretty important. Sichuan Fudi New Energy Co., Ltd., which started back in 1998, has been focusing on making and selling fluoroelastomers and other fluorinated rubber products for over 20 years. We’ve built up a ton of expertise, offering everything from fluoroelastomer base polymers and FKM/FPM precompounds to vulcanizing agents, all tailored specifically for Fluorocarbon Rubber. In this blog, I’ll walk you through seven key tips that can help boost the performance and efficiency of Fluorocarbon Rubber in various industrial settings. Whether you’re manufacturing or just trying to get the most out of your materials, these tips can help you optimize your processes, make better products, and ensure everything lasts longer and stays reliable.

Understanding Fluorocarbon Rubber: Properties and Industrial Relevance

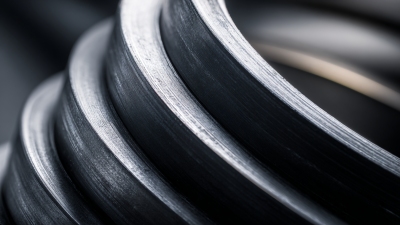

You know, fluorocarbon rubber is pretty amazing when it comes to resisting chemicals, staying stable under high temperatures, and being super versatile. It’s like that go-to material in a bunch of industrial settings. It has some really cool properties, like how it's pretty much gas-proof and can hold up against tough conditions without breaking a sweat. That’s why it’s such a lifesaver in environments where regular materials just can’t cut it—think oils, fuels, and areas with harsh chemicals. What’s even more interesting is that folks are finding ways to make it perform even better. By tweaking things like adding fluorocarbon surfactants or doing some chemical treatments, its capabilities get a nice boost.

Lately, researchers have been diving into how modifying these fluorocarbon surfactants can improve foam properties. That’s a big deal for things like fire suppression and other industrial uses. For example, adding a compound like diethylene glycol butyl ether actually helps make smaller bubbles and speeds up how quickly the foam spreads, which is pretty handy. On top of that, applying special fluorocarbon-based surface treatments not only makes composite materials stronger but also helps natural fibers soak up less moisture. All these new tricks really show how important fluorocarbon materials are getting in today’s tech and industrial scenes—meeting those really tough demands out there.

Key Applications of Fluorocarbon Rubber in Industrial Settings

You know, fluorocarbon rubber has really become a go-to material in lots of different industries, thanks to its amazing properties like resisting high temperatures and staying stable chemically. One area where it’s especially popular is in the automotive world, where it’s used for seals, gaskets, and tubing — stuff that needs to hold up under tough conditions. Funny enough, the global market for synthetic rubber is expected to jump from around $32.8 billion in 2024 to about $48.2 billion by 2032, so it’s clear there’s a growing demand for high-performance materials like fluorocarbon rubber. Plus, the market for liquid diene rubber is also projected to hit around $6.8 billion by 2030, showing just how much advanced elastomers are needed in really demanding environments.

When you're working with fluorocarbon rubber, a little tip — make sure to get the curing process right. That really helps improve its mechanical strength. Like, it can usually handle temps up to 200°C pretty well, but pushing it too far during processing? That can actually mess with its durability. Also, it’s super important to understand how it interacts with different chemicals. For example, fluorocarbon rubber performs great in aggressive chemical environments, but choosing the right formulation based on what you’re using it for is key to making sure it performs at its best.

And one more thing — pay close attention to quality control during manufacturing. Considering how fast sectors like automotive and chemical processing are growing, keeping standards high is essential. You’ll want to use proper testing methods to ensure your rubber meets all the necessary specs and is free of defects. Trust me, staying on top of these details really pays off in the end.

Essential Safety Practices for Handling Fluorocarbon Rubber

Whenever you're working with fluorocarbon rubber in industrial settings, safety really needs to be your first priority, no exception. One of the most important things is making sure you're always wearing the right personal protective gear—think gloves, goggles, and respirators—especially if there's dust or fumes floating around. These PPE items are basically your first line of defense against any health issues that could come from handling these materials.

On top of that, proper training is a big deal. Anyone working with these rubber materials should really understand what they’re dealing with—like their chemical makeup and the possible health risks involved. It’s also super important to go over emergency procedures, just in case something goes wrong—knowing what to do quickly can make all the difference. Keeping things tidy and organized in the workspace helps too. It not only keeps things running smoothly but also keeps everyone safe and healthy. Honestly, a little bit of care goes a long way in making sure everyone stays safe while doing their work.

Maintenance and Storage Tips for Fluorocarbon Rubber Components

When you're working with fluorocarbon rubber parts in industrial settings, it’s super important to take good care of them—proper storage and maintenance really make all the difference if you want these components to last. I mean, fluorocarbon rubber is pretty impressive because it can handle high temperatures, harsh chemicals, and UV rays, but if you ignore its needs, it can fail far too soon. According to the Rubber Manufacturers Association, putting these rubber parts in the wrong storage conditions can cut their lifespan by up to half. That just goes to show how crucial good maintenance habits are.

To get the most bang for your buck and keep these components working smoothly, make sure to store them in a cool, dry spot—away from direct sunlight and extreme temps. Also, steer clear of places where they might come into contact with strong acids or bases—that's a quick way to cause some serious damage. Regularly checking for any signs of wear or cracks is another smart move. If you do find any issues, don’t wait around—repair or replace them ASAP so your operations keep running without a hitch.

Oh, and here’s a tip—clean your fluorocarbon rubber parts with the right solvents. Using the wrong cleaning agents can actually harm the surface and mess with their durability. The American Institute of Chemical Engineers points out that incompatible cleaners can cause surface deterioration, which obviously isn’t what you want. By following these simple tips on storage and maintenance, you'll help ensure those rubber components stay in tip-top shape for as long as possible.

7 Best Practices for Working with Fluorocarbon Rubber in Industrial Applications - Maintenance and Storage Tips for Fluorocarbon Rubber Components

| Best Practice | Description | Importance | Storage Tips |

|---|---|---|---|

| Proper Cleaning | Use appropriate solvents and avoid abrasive materials. | Prevents damage and prolongs lifespan. | Store in a clean, dry place post-cleaning. |

| Avoid Direct Sunlight | Protect components from UV radiation. | Maintains material integrity. | Use opaque storage containers. |

| Control Temperature | Keep in a stable temperature environment. | Prevents thermal degradation. | Ideal storage temperature: 15°C to 25°C. |

| Avoid Contact with Oils | Limited compatibility with certain oils. | Prevents swelling and material failure. | Keep away from oil storage areas. |

| Regular Inspections | Routine visual checks for wear and tear. | Identifies potential issues early. | Check every 6 months. |

| Avoid Mechanical Stress | Limit bending or twisting of components. | Reduces risk of failure during operation. | Store in a manner that avoids pressure points. |

| Label Storage Conditions | Clearly mark storage area with conditions. | Ensures all personnel are aware of handling requirements. | Include temperature and humidity levels. |

Common Mistakes to Avoid When Working with Fluorocarbon Rubber

When you're working with fluorocarbon rubber in industrial setups, it's super important to watch out for some common mistakes that can really cause big problems down the line. One of the biggest slip-ups? Ignoring the right temperature range during processing. Honestly, if the rubber gets too hot, it can start breaking down, which kinda messes up its performance and lifespan. So, always double-check the manufacturer's guidelines — sticking to those specs is key to getting good results.

Another thing to keep in mind is making sure your materials play well together. Using fluorocarbon rubber with incompatible substances can lead to all sorts of reactions that might ruin the final product. It’s a smart move to do thorough compatibility checks before you use it in your manufacturing process — better safe than sorry, right?

Oh, and don’t forget about curing times! Skipping or rushing that step can seriously mess with the mechanical properties of the rubber. Just follow the recommended curing durations, and you’ll be more likely to end up with a durable, high-quality end product.

Innovative Manufacturing Techniques for Fluorocarbon Rubber Products

You know, fluorocarbon rubber is pretty impressive stuff—it's really known for how well it stands up to heat and resists chemicals. That’s why you'll find it used in all sorts of industries, from sealing parts in cars to components in aerospace. Over the years, the way these products are made has improved a lot, really boosting their performance and lifespan. Companies now rely on clever techniques like precise molding and adding new, advanced materials to get the best out of it. I recently came across a report from MarketsandMarkets that said the global market for fluoropolymers is expected to hit around USD 10.79 billion by 2025. That’s mostly because folks are looking for high-performance materials more than ever, which pushes manufacturers to get even more creative with their methods.

One exciting development is the use of advanced extrusion techniques. Not only do these methods cut down on waste, but they also help make sure that each product batch is consistent—big plus when it comes to quality. Actually, a study from Research and Markets pointed out that moving towards automated manufacturing can boost efficiency by up to 30%. And of course, incorporating solid quality control steps right into the production process means every batch of fluorocarbon rubber is up to snuff with industry standards.

As more industries put a focus on sustainability and efficiency, I think refining how we make these materials is gonna be key to keeping up with market demands—and pushing the boundaries even further.

FAQS

: Fluorocarbon rubber is known for its exceptional chemical resistance, thermal stability, low gas permeability, and excellent resilience under harsh conditions.

Its remarkable properties make it indispensable in environments where conventional materials may fail, particularly in processes involving oils, fuels, and aggressive chemicals.

Performance can be improved through strategic modifications such as the incorporation of fluorocarbon surfactants and chemical treatments.

One common mistake is neglecting the proper temperature ranges during processing, which can lead to degradation and compromise performance.

Conducting compatibility checks with other materials is crucial to prevent adverse reactions that could affect the integrity of the final product.

Techniques such as precision molding, advanced extrusion methods, and the use of advanced additives are enhancing the performance and durability of fluorocarbon rubber products.

The adoption of automated manufacturing processes can increase production efficiency by up to 30%, improving consistency and reducing waste.

Proper curing times are essential to achieve the desired mechanical properties; inadequate curing can lead to product failures.

Fluorocarbon rubber is commonly utilized in industries such as automotive, aerospace, and other sectors that require high-performance materials.

The global fluoropolymer market is projected to reach USD 10.79 billion by 2025, indicating a rising demand for high-performance materials.

Conclusion

When you’re delving into the world of industry, getting a good handle on Fluorocarbon Rubber is pretty important. It’s got some pretty amazing traits—like standing up really well against chemicals and heat—which makes it a go-to in stuff like cars, airplanes, and chemical plants. But, if you’re working with this material, you’ve gotta be careful—following the right safety steps and maintenance tips is key to keeping things running smoothly and making your parts last longer.

Oh, and a tip: steer clear of common mistakes—that can make a big difference with how well everything works. Plus, there are some cool new manufacturing techniques changing the game, making these materials even better for all kinds of cutting-edge uses. Here at Sichuan Fudi New Energy Co., Ltd., we’ve been in the biz for over 20 years, specializing in fluoroelastomers and other fluorinated rubbers—and we’re constantly adapting to meet the industry’s ever-changing needs.

Related Posts

-

Understanding Perfluoroelastomer O Rings Benefits and Applications in Global Markets

-

Optimizing Performance: Innovative Solutions Using FKM Material Properties

-

The Future of Viton Sponge Rubber in Innovative Industrial Applications

-

How to Choose the Right Viton Material for Your Industrial Needs

-

Top Strategies for Boosting Efficiency with Material Fkm Viton in Industrial Applications

Blog Tags:

Charlotte

-

Phone

-

E-mail

-

Whatsapp

-

Top