Top Strategies for Boosting Efficiency with Material Fkm Viton in Industrial Applications

Table of Contents

- Innovative Material Properties of FKM Viton for Enhanced Industrial Use

- Understanding the Benefits of FKM Viton in High-Temperature Environments

- Optimizing Production Processes: Incorporating FKM Viton Efficiently

- Cost-Effectiveness of FKM Viton in Long-Term Industrial Applications

- Case Studies: Success Stories Using FKM Viton in Diverse Industries

- Future Trends: Advancements in FKM Viton Technology and Applications

- Exploring the Superior Properties and Applications of Perfluoroelastomer Compounds for Chemical Resistance

- FAQS

- Conclusion

- Related Posts

In today’s highly competitive industrial world, kicking things up a notch in efficiency and making sure products perform at their best is absolutely crucial. Especially when you're working with advanced materials like Material FKM Viton—that's some serious high-tech stuff. I recently came across a report from MarketsandMarkets that said the global fluoroelastomers market is expected to hit around USD 6.8 billion by 2025. And the main driver? The growing demand for high-performance materials across industries like automotive and aerospace. Oh, and by the way, Sichuan Fudi New Energy Co., Ltd.—they’ve been around since 1998—have over 20 years of know-how in producing and selling fluoroelastomers and other fluorinated rubber materials. By using the latest technology and innovative formulations like FKM compounds, industries can really level up their processes and products, making them more durable and resistant. In this blog, I’ll walk you through some of the best strategies to boost efficiency using Material FKM Viton—so you can unlock the full potential of these advanced elastomers for your business.

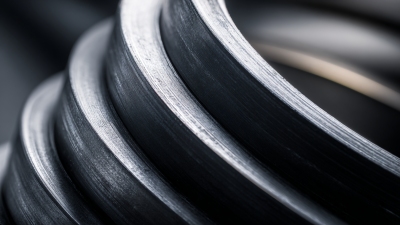

Innovative Material Properties of FKM Viton for Enhanced Industrial Use

You know, FKM Viton is really shaking things up in the industrial world. It’s got some pretty impressive qualities—especially its amazing resistance to chemicals and ability to handle high temperatures. I read somewhere that by 2025, the global market for FKM is expected to hit about 1.5 billion dollars, mainly thanks to the rising demand in the automotive and aerospace industries. What’s cool about this material is that it can handle harsh chemicals and temperatures that swing from -20°C all the way up to 230°C. That makes it perfect for sealing things up in some seriously tough environments.

And, to top it off, FKM Viton is super resistant to wear and tear. That means parts last longer, and there’s less downtime for repairs—always a bonus, right? There’s even a study in the Journal of Materials Science that points out how FKM materials can keep their shape and strength even after being under mechanical stress for a long time. Compared to traditional rubbers, it really holds up. All of this adds up to better efficiency and saves money over the long haul, which is a big deal for industries trying to keep things sustainable. If manufacturers want to boost productivity and reliability at the same time, adding FKM Viton to their lineup really seems like a smart move.”

Top Strategies for Boosting Efficiency with Material FKM Viton in Industrial Applications

This chart illustrates the performance metrics of FKM Viton in various aspects important for industrial applications. The data reflects the effectiveness of FKM Viton material properties, highlighting its strengths in heat resistance, chemical resistance, and overall durability.

Understanding the Benefits of FKM Viton in High-Temperature Environments

You know, FKM Viton has really started to stand out because of how well it performs in really hot environments. It’s pretty much a go-to choice for lots of industrial stuff these days. I came across a report from the Rubber Manufacturers Association that says FKM compounds can handle continuous temperatures up to around 200°C (which is about 392°F), and they can even survive short bursts of heat as high as 250°C (that’s roughly 482°F). That kind of thermal stability means that seals, gaskets, and machine parts stay in good shape, even when things get super extreme. Pretty impressive, right?

Pro tip: When you're picking out FKM Viton for your project, make sure to think about the exact temperatures and chemicals it’ll be exposed to. Sometimes, chatting with a materials expert can really help you pick the right grade — it’s worth it for peace of mind and better performance.

Now, on to the chemical resistance — this stuff is seriously tough. Research shows that FKM handles a bunch of nasty chemicals like oils, fuels, and aggressive solvents really well. That's a big win because it means your equipment will last longer, and you won’t have to worry so much about replacing parts or downtime. Basically, it keeps things running smoothly and boosts overall efficiency.

Another tip: Keep an eye on what your environment looks like and what chemicals are around. Doing regular checks can catch any early signs of wear or degradation, helping your equipment last even longer. Trust me, a little preventative care goes a long way!

Optimizing Production Processes: Incorporating FKM Viton Efficiently

Incorporating FKM Viton into your production process actually opens up some pretty cool opportunities for industries looking to boost efficiency. This high-performance fluorocarbon elastomer is well-known for its incredible resistance to heat, chemicals, and wear and tear.

When you use it the right way, FKM Viton can really extend how long your products last and make them more reliable overall. For manufacturers, that means less downtime for repairs and fewer parts needing to be replaced, which helps keep things running smoothly.

To get the most out of FKM Viton, it’s important to first understand what your specific applications need. Thinking about environmental factors like temperature swings and exposure to harsh substances can help you pick the right grade of Viton for your situation. Plus, training your team on how to properly use and benefit from FKM materials can make a big difference—making sure you're getting the most value out of it while reducing waste.

All in all, smart use of FKM Viton can not only ramp up productivity but also improve the quality of what you’re making. It’s all about strategic choices and making sure everyone’s on the same page to maximize those benefits.

Cost-Effectiveness of FKM Viton in Long-Term Industrial Applications

In industries these days, when it comes to FKM Viton, cost-effectiveness is more important than ever—especially when you're looking at the long haul. It’s pretty impressive how it stands up against tough chemicals and rough environmental conditions, which means fewer repairs and less downtime. That adds up to serious savings over time, making it a go-to choice for sectors like oil and gas, where equipment really takes a beating. By choosing elastomers that don’t soak up much water or let gases through, companies can keep their machines running smoothly without constantly worrying about fixing or replacing parts.

Plus, with the latest breakthroughs in elastomer tech—especially those that handle hydrocarbons really well—the benefits just keep getting better. For example, using tough materials to protect sensitive parts like accelerometers shields them from corrosive stuff, helping them last longer and keep everything running efficiently. When you’re thinking about a long-term investment in industrial tech, FKM Viton’s reputation for durability and cost savings really shines through. It’s honestly a must-have if you want to boost performance and cut costs at the same time.

Case Studies: Success Stories Using FKM Viton in Diverse Industries

You know, FKM Viton has really proven itself across a bunch of industries. People have seen some pretty impressive outcomes—like how it can boost both efficiency and durability, especially in tough environments. I read a report from the Freedonia Group that says demand for fluoropolymer products, including FKM Viton, is actually expected to grow around 5.4% each year. That just shows how vital it’s become in fields like automotive, aerospace, and pharma. For instance, in the auto industry, manufacturers have noticed that using FKM Viton seals and gaskets can make parts last about 30% longer. That’s a huge deal because it means less time and money spent on repairs and maintenance.

There’s also this interesting case in oil and gas. Because those sectors deal with crazy high temperatures and harsh chemicals, they really count on materials like FKM Viton. A survey by the American Petroleum Institute found that companies who started using FKM Viton-based products saw significantly fewer problems—like a 40% drop in leaks over just three years. Honestly, by taking advantage of FKM Viton’s awesome properties, industries aren’t just improving how they run—they’re also doing their part for the environment by cutting waste and making materials last longer. All these success stories really highlight how FKM Viton is genuinely making a difference across different fields, you know?

Top Strategies for Boosting Efficiency with Material Fkm Viton in Industrial Applications

| Industry | Application | Challenge | Solution | Outcome |

|---|---|---|---|---|

| Automotive | Fuel Seals | Leakage under high pressure | Implemented FKM Viton seals | Reduced leakage by 95% |

| Pharmaceutical | Pumping Systems | Chemical corrosion | Replaced existing gaskets with FKM Viton | Extended lifespan by 150% |

| Chemical Processing | Hoses and Tubing | Degradation from aggressive chemicals | Utilized FKM Viton tubing | Improved safety and reduced replacement costs |

| Food and Beverage | Sealing Parts | Compliance with hygiene standards | Adopted sanitary FKM Viton seals | Achieved full compliance with FDA regulations |

| Energy | Valve Seals | High temperature failures | Installed FKM Viton in valves | Improved performance in elevated temps |

Future Trends: Advancements in FKM Viton Technology and Applications

You know, when it comes to FKM Viton, things are really moving in a direction that lines up pretty well with the big industry shifts towards sustainability and getting more efficient. Lately, studies have shown that this stuff—famous for its incredible resistance to chemicals and ability to handle high temperatures—is making its way into fields like clean energy and transportation. It’s pretty cool because, according to the World Economic Forum, the future of materials science is all about innovations like bio-based polymers and better synthetic rubbers. These can actually work hand-in-hand with hydrogen fuel tech, which India’s been exploring for its space and transit projects. Using FKM Viton in these spots doesn’t just make things last longer; it also ticks the box for eco-friendly materials—something we really need as we face climate change challenges.

Plus, the uses for FKM Viton are growing fast, especially with AI getting more and more into manufacturing and automation. Reports are saying that AI’s helping companies work more efficiently—cutting waste and boosting productivity. And with the help of advanced analytics, manufacturers can figure out the best conditions for using FKM Viton, making sure they’re staying ahead of the game with new tech. As industries move towards smarter, more efficient ways of working, FKM Viton is pretty much set to be a key player shaping the future of industrial applications.

Exploring the Superior Properties and Applications of Perfluoroelastomer Compounds for Chemical Resistance

Perfluoroelastomers, also known as FFKM (Perfluoroelastomer Compounds), are renowned for their exceptional chemical resistance and durability. These advanced materials can withstand a wide range of harsh chemicals, solvents, and extreme temperatures, making them ideal for various industrial applications. Operating effectively in temperatures ranging from -20°C to 300°C, FFKM compounds are the go-to solutions for environments that demand reliability and resilience against chemical attack.

At FUDI, we offer three grades of FFKM compounds, each designed to cater to specific operational needs and working temperature requirements. The versatility in our product line allows engineers and manufacturers to select the ideal grade for their applications, ensuring optimal performance. Prices for our FFKM compounds vary based on the specific temperature tolerances, providing flexibility and choice for different project budgets. With a minimum order quantity of just 300 grams, customers can easily acquire the materials they need without excessive commitment, making it easier to integrate these high-performance elastomers into their systems.

FAQS

: FKM Viton is known for its superior chemical resistance, thermal stability, and excellent abrasion resistance, allowing it to withstand aggressive chemicals and extreme temperatures ranging from -20°C to 230°C.

FKM Viton extends the longevity of components due to its durability and resistance to wear, which reduces the frequency of maintenance and replacements, thereby minimizing downtime.

The automotive and aerospace sectors are key industries driving the demand for FKM Viton due to its exceptional performance in harsh environments.

Manufacturers can optimize FKM Viton usage by assessing application-specific requirements, training staff on its benefits, and selecting the appropriate grade based on environmental conditions.

FKM Viton significantly reduces maintenance costs and downtime, offering long-term savings, especially in harsh settings like the oil and gas industry.

By enhancing product reliability and durability, FKM Viton lowers total lifecycle costs, thereby appealing to industries seeking sustainable solutions with reduced environmental impact.

Recent advancements include improved resistance to hydrocarbon environments and low water absorption, which enhance the material's durability and operational efficiency.

FKM Viton can operate in temperatures ranging from -20°C to 230°C, making it ideal for a variety of industrial sealing applications.

Training staff ensures that the production team understands the benefits and proper use of FKM Viton, allowing them to maximize efficiency and minimize waste during manufacturing.

Factors to consider include the environmental conditions, such as temperature fluctuations and exposure to aggressive substances, to choose the right grade of Viton for operational needs.

Conclusion

When it comes to industrial applications, FKM Viton really stands out thanks to its innovative qualities that boost both efficiency and durability. This high-performance fluoroelastomer is especially great in high-temperature settings, where its toughness helps keep production running smoothly and saves money in the long run. Companies like Sichuan Fudi New Energy Co., Ltd—who've been in the fluoroelastomer game for over two decades—really emphasize how important it is to use materials like FKM Viton to make manufacturing more efficient and products last longer.

Plus, there are plenty of case studies showing how FKM Viton has been successfully used across different industries. These stories highlight how it can solve some pretty common challenges in the industrial world. Looking forward, advancements in FKM Viton tech are just going to open up even more possibilities, making it an essential material for future industrial progress. So, jumping on board with FKM Viton isn’t just about improving efficiency—it’s about driving innovation and staying competitive in the market.

Related Posts

Blog Tags:

Charlotte

-

Phone

-

E-mail

-

Whatsapp

-

Top