How to Choose the Right Viton Sheet for Your Industrial Needs

Table of Contents

- Understanding Viton Rubber: Properties and Applications in Industry

- Key Factors to Consider When Selecting Viton Sheets for Specific Environments

- Comparing Viton Grades: Which Type Best Suits Your Chemical Compatibility Needs?

- Evaluating Thickness and Size: Optimizing Viton Sheet Configurations for Performance

- Cost vs. Quality: How to Balance Budget and Long-Term Durability with Viton Sheets

- Industry Standards and Certifications: Ensuring Compliance When Choosing Viton Products

- Innovative Applications and Benefits of Bisphenol Curable Fluoroelastomer Copolymer in Modern Industries

- FAQS

- Conclusion

- Related Posts

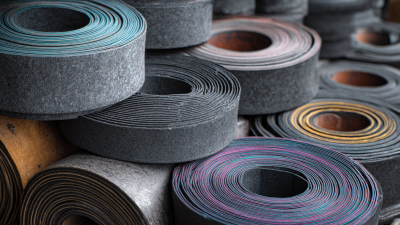

So, when you're trying to pick out the right Viton Sheet for your industrial needs, it’s really important to think about a bunch of factors that can affect how well it works and how long it lasts.

Viton, which is a type of fluoropolymer made by DuPont, is pretty famous for its amazing resistance to chemicals and ability to handle super hot or cold conditions—think temperatures from around -20°F up to 400°F (-29°C to 204°C).

It's interesting—industry reports suggest that the global market for fluoroelastomers is expected to hit about $6 billion by 2025, mainly because industries like automotive, aerospace, and chemical processing are demanding more of these materials.

Oh, and by the way, Sichuan Fudi New Energy Co., Ltd., has been around since 1998, and they specialize in making and selling fluoroelastomers, including Viton Sheets.

They’ve got over 20 years of know-how when it comes to developing top-quality fluorinated rubber products.

To get the best results, it really pays to understand what your specific environment needs and know the different properties of various Viton Sheets—that way, you’ll get reliable performance and longevity in your applications.

Oh, and by the way, Sichuan Fudi New Energy Co., Ltd., has been around since 1998, and they specialize in making and selling fluoroelastomers, including Viton Sheets.

They’ve got over 20 years of know-how when it comes to developing top-quality fluorinated rubber products.

To get the best results, it really pays to understand what your specific environment needs and know the different properties of various Viton Sheets—that way, you’ll get reliable performance and longevity in your applications.

Understanding Viton Rubber: Properties and Applications in Industry

Viton rubber is a type of fluoropolymer that's pretty impressive when it comes to handling heat, chemicals, and oxidation. It’s no wonder it’s a go-to material in all kinds of industrial settings. One of the coolest things about Viton is its high-temperature stability—it can work well in environments from about -20°F all the way up to 400°F, and some versions can even take on temperatures up to 600°F! That kind of thermal resilience is actually a big deal, especially in industries like aerospace, automotive, and chemical processing, where conditions can get really extreme and unpredictable.

But it’s not just about heat. Viton also stands out because of its excellent resistance to chemicals—more so than many other rubbers—making it perfect for seals and gaskets in petrochemical plants and pharma stuff. Plus, it doesn’t easily deform under pressure thanks to its low compression set, so it keeps performing reliably over time, even in tough conditions. If you're in an industry trying to pick the right Viton sheet for your specific needs, understanding these properties is key. It can really boost the reliability and efficiency of your operations—and that’s no small thing.

Key Factors to Consider When Selecting Viton Sheets for Specific Environments

When you're choosing Viton sheets for specific industrial settings, there are a few key things you really wanna keep in mind to make sure everything works perfectly. First off, you gotta think about the chemical resistance of the Viton—does it match up with the stuff it'll be exposed to? I came across this pretty thorough chemical compatibility report from 2021 by the Chemical Resistance Institute, and it says Viton does a stellar job resisting a whole bunch of chemicals—like fuels, oils, and aggressive solvents. That’s why it's such a popular pick in industries like automotive and aerospace. To make the right call, it helps to really know what chemicals are present in your environment so you can pick the right grade of Viton that won't break down over time.

Temperature is also a big deal. Luckily, Viton sheets can handle pretty extreme temps—they stay stable from about -40°F all the way up to 400°F. The ASTM did some tests and found that certain grades of Viton outperform other elastomers when it comes to heat resistance—some other materials might melt or get misshapen under heat, but not Viton. So, whether you’re working in super hot manufacturing conditions or dealing with temperature swings outside, it’s super important to figure out what kind of thermal environment you’re dealing with. Picking the right Viton sheet for your specific situation will save you a lot of hassle down the line.

Comparing Viton Grades: Which Type Best Suits Your Chemical Compatibility Needs?

When you're trying to pick the right Viton sheet for your industrial needs, it’s pretty important to get a good handle on the different grades and how they stand up against various chemicals. Viton, as you probably know, is a high-performance fluoroelastomer — and it comes in several grades, each suited to specific applications. For example, the so-called Fluoroelastomer FKM (like Viton A and B) has different levels of resistance to different chemicals. I read somewhere, from a report by the American Chemical Society, that Viton A does really well against a wide range of acids, while Viton B tends to perform better when dealing with bases and solvents. Basically, it’s all about matching the right grade to the chemicals you'll be working with.

And it’s not just about chemical resistance—picking the right Viton can actually save you some serious money in the long run. Industry studies, like one from ASTM International’s Rubber Division, show that choosing the correct elastomer can boost the lifespan of your seals and gaskets by up to 60%. That means less downtime and fewer replacements, which is always a plus. Also, you gotta think about the specific chemicals you’ll be exposed to—like aromatic hydrocarbons. For example, Viton GFLT is known to be super resistant to fuels and aggressive chemicals, making it perfect for automotive or aerospace uses. So, getting familiar with these differences really helps in picking the best Viton sheet for your unique chemical environment, ensuring everything runs smoothly and efficiently.

Evaluating Thickness and Size: Optimizing Viton Sheet Configurations for Performance

When you're picking out the right Viton sheet for your industrial needs, figuring out the right thickness and size is actually pretty important. Viton sheets come in all sorts of thicknesses, and the choice you make can really impact how long they last and how well they resist chemicals, heat, and other environmental stuff. For example, a thicker sheet might give your components better mechanical support and last longer, but on the flip side, a thinner one could be more flexible—great for tight spots or tricky installations.

In today’s busy and complex industrial settings, just like dealing with the crowded RF spectrum in wireless tech, you gotta plan carefully and think things through. Knowing what your specific application demands and how the Viton sheet will work with other materials is key. It’s a bit like doing strategic planning in RF design—if you get it right, you can avoid a lot of headaches down the line. By paying close attention to thickness and size, you’re setting yourself up for better performance and reliability overall.

Cost vs. Quality: How to Balance Budget and Long-Term Durability with Viton Sheets

When you're picking out the right Viton sheet for your industrial needs, it’s really all about finding that sweet spot between cost and quality. I mean, sure, choosing cheaper Viton options can save you a bit upfront, but honestly, they tend to wear out faster, meaning more frequent replacements and way more downtime. Over time, those little savings can add up to more than you'd think. There was this study by the Rubber Manufacturers Association that found investing in better-quality Viton could cut maintenance costs by around 30% over five years—pretty significant, right? That really shows how important it is to think about durability and performance, not just the initial price tag.

Another tip? Make sure you really evaluate your application's conditions—things like temperature and chemical exposure—so you pick a Viton sheet that can handle the job without sacrificing quality. And don’t forget, chatting with your supplier can be a game-changer—they often have great insights on which grade of Viton will give you the best bang for your buck.

Also, it’s worth noting that while top-tier Viton sheets might seem pricey at first, their amazing resistance to heat, chemicals, and aging can totally justify the cost. According to data from the American Chemistry Council, companies that go for high-quality materials end up experiencing fewer failures and generally run more smoothly. Investing in solid, durable Viton sheets isn’t just about performance—it can actually save you quite a bit of money in the long run, no doubt about it.

Industry Standards and Certifications: Ensuring Compliance When Choosing Viton Products

Hey, when you're choosing Viton sheets for industrial stuff, it’s super important to make sure they hit all the right standards and certifications. Viton, as you might know, is a type of fluoropolymer that’s really famous for handling extreme temperatures and tough chemicals. To be confident in your choice, it’s a good idea to check out certifications like ASTM D2000 and SAE J200. These standards set the bar for testing elastomer performance, so you know the materials can stand up to the kind of heavy-duty conditions they’ll face in real-world industrial setups. I read in a recent market report from MarketsandMarkets that the global fluoropolymer market is expected to hit around USD 10.9 billion by 2025—that’s a clear sign how much folks are leaning on high-quality, certified materials that meet strict compliance.

In industries like automotive, aerospace, and chemical processing, having the right certifications isn’t just a bonus—it’s pretty much mandatory. Take food processing, for example—getting FDA approval on products is key to making sure there’s no contamination and everything’s safe. Plus, showing off those certifications isn’t just about following rules; it’s about giving customers confidence that your product will hold up under the pressure. According to a report by Grand View Research, roughly over half of industrial pros—about 55%—say they prioritize certifications and compliance over just price when they’re picking out materials. That really underlines just how much everyone values reliability and peace of mind when buying stuff from suppliers.

Viton Sheet Material Compliance Based on Industry Standards

Innovative Applications and Benefits of Bisphenol Curable Fluoroelastomer Copolymer in Modern Industries

The innovative applications of bisphenol curable fluoroelastomer copolymer are revolutionizing modern industries, particularly in sectors demanding high-performance materials. This type of fluoroelastomer precompound is characterized by its unique formulation, which includes a base polymer and carefully selected crosslinkers. This allows manufacturers to customize their products to meet specific requirements related to color and hardness. The versatility of these materials is evident in their widespread use across various applications, from automotive seals and gaskets to aerospace components, where resistance to heat, chemicals, and aging is critical.

Recent industry reports underscore the growing demand for high-performance elastomers. For instance, the global fluoroelastomer market is projected to reach USD 3.6 billion by 2026, growing at a CAGR of 6.5% (Research and Markets, 2022). This surge can be attributed to the increasing awareness of safety and environmental standards, as seen with the rise of REACH and RoHS certifications for materials used in manufacturing. Bisphenol curable fluoroelastomers stand out as being PFOA and PFAS free, aligning with regulatory shifts and reducing environmental impact, making them an attractive choice for forward-thinking companies looking to enhance their sustainability profiles.

Furthermore, these fluoroelastomers boast a shelf life of up to two years, appealing to manufacturers needing reliable materials that can be stored without frequent degradation. By leveraging the adjustable formulations of fluoroelastomer precompounds, industries can optimize their production processes and improve the performance of end products, showcasing a significant shift towards innovation and efficiency in material science.

FAQS

: Viton rubber is a type of fluoropolymer known for its exceptional resistance to heat, chemicals, and oxidation. It can function effectively in environments ranging from -20°F to 400°F, with some formulations capable of enduring temperatures up to 600°F.

Viton rubber is preferred in various industries, particularly aerospace, automotive, and chemical processing, due to its high-temperature stability and chemical resistance.

Chemical resistance is crucial because Viton outperforms many other rubber materials when exposed to oils, fuels, and aggressive chemicals, making it ideal for seals and gaskets in petrochemical and pharmaceutical applications.

Temperature stability is critical because it helps determine which grade of Viton can withstand specific thermal environments, ensuring the material maintains integrity under extreme temperatures that can reach up to 400°F.

Key factors include matching the chemical resistance of Viton with the substances it will encounter, assessing temperature stability, and evaluating the thickness and size of the sheets for optimal performance.

A thicker Viton sheet generally provides enhanced mechanical stability and durability, while a thinner sheet offers increased flexibility, making it important to choose the right thickness based on the specific application requirements.

The Chemical Resistance Institute provides comprehensive chemical compatibility reports that help users understand how different grades of Viton will resist various chemicals, aiding in the selection process for industrial environments.

Compression set refers to the deformation experienced by a material under pressure. For Viton rubber, a low compression set is important as it minimizes deformation, ensuring long-lasting performance in dynamic sealing applications.

By meticulously planning and evaluating configurations, understanding specific demands, and assessing how the Viton sheet will interact with other materials, users can mitigate potential issues and enhance reliability.

It is essential to evaluate the chemical compatibility, temperature stability, and the appropriate physical dimensions such as thickness and size to ensure the selected Viton sheet meets performance and operational needs.

Conclusion

The article titled "How to Choose the Right Viton Sheet for Your Industrial Needs" really breaks down everything you need to know about picking the right Viton Sheet—something that’s super important for a bunch of industrial applications. It kicks things off by highlighting what makes Viton rubber special, like its toughness and how well it handles harsh chemicals. Then, it walks you through the main things to keep in mind when choosing a Viton Sheet, like where you plan to use it and what exactly you need it to do.

It also dives into the different grades of Viton out there, helping you figure out which one is best for your specific chemical needs. Plus, it points out that size and thickness really matter if you want things to work smoothly and last longer. The article doesn’t forget to talk about what’s worth the investment—balancing cost with durability—plus, it stresses how important industry standards and certifications are to make sure you’re on the right side of regulations. For companies like Sichuan Fudi New Energy Co., Ltd., which has been around for over 20 years in the fluoroelastomer game, knowing these details is pretty much key to making sure they pick the right Viton Sheet—something that hits both their performance goals and complies with industry rules.

Related Posts

-

Ultimate Guide to Understanding the Benefits of Fkm Rubber in Industrial Applications

-

The Future of Viton Sponge Rubber in Innovative Industrial Applications

-

How to Choose the Right Hnbr Viton for Your Industrial Applications

-

7 Reasons Why FKM Is Viton the Best Choice for Your Industrial Needs

-

The Ultimate Guide to Selecting Fluoroelastomer Sheets: Key Features and Industry Insights

-

Understanding Perfluoroelastomer O Rings Benefits and Applications in Global Markets

Blog Tags:

Eleanor

-

Phone

-

E-mail

-

Whatsapp

-

Top