Why Choosing Viton Strips is Essential for Industrial Applications

Table of Contents

- Understanding the Superior Chemical Resistance of Viton Strips in Industrial Settings

- Key Benefits of Viton Strips: Longevity and Durability in Harsh Environments

- Comparative Analysis: Viton vs. Traditional Rubber Strips in Performance and Cost

- Viton Strips in High-Temperature Applications: Reliability Metrics and Case Studies

- The Role of Viton Strips in Meeting Industry Standards and Regulatory Compliance

- Market Trends: The Growing Demand for Viton Strips in Industrial Applications

- Exploring the Advantages and Applications of Great Chemical Resistance Perfluoroelastomer Compounds in Modern Industries

- FAQS

- Conclusion

- Related Posts

In the fast-changing world of industrial applications, picking the right materials can really make or break your efficiency, reliability, and how long things last. Take Viton Strips, for example — they’re known for their incredible resistance to chemicals and ability to handle high temperatures, making them a go-to for the toughest environments. Sichuan Fudi New Energy Co., Ltd., has been leading the charge in this space since 1998. They’ve been specializing in creating and selling fluoroelastomer and other fluorinated rubber materials for over 20 years. Their product lineup includes top-quality stuff like fluoroelastomer base polymers, FKM/FPM precompounds, and fluorosilicone rubber — all designed to meet the strictest industry standards. Thanks to their expertise and dedication to quality, they’re always ready to help industries pick the perfect Viton Strips, so things run smoother and last longer in the long run.

Understanding the Superior Chemical Resistance of Viton Strips in Industrial Settings

You know, Viton strips are really gaining a reputation as essential components in a bunch of industrial setups, especially because of how well they resist chemicals. I came across a report from the American Chemical Society that highlights just how stable Viton is when it comes to all sorts of chemicals—think tough solvents and fuels. That means it can hold up even in pretty brutal conditions. This is pretty important for fields like aerospace, auto manufacturing, and chemical industries, where failing materials can potentially cause serious problems.

When you're picking materials for seals, gaskets, or O-rings, it’s super important to think about what chemicals they'll actually come into contact with. For example, Viton can handle temperatures from about -20°F up to 425°F, which makes it perfect for high-heat situations. Plus, studies have shown that Viton keeps its properties even after being exposed to tough environments over time—something a lot of other rubber compounds struggle with. That kind of durability means fewer replacements, saving you some bucks in the long run.

A quick tip: To get the most out of your Viton strips, make sure they're installed properly to avoid compression set—that’s when they lose their shape and effectiveness. Regular check-ups are also a good idea; catching wear and tear early can save you from bigger issues down the road. And if you're unsure about which grade of Viton to go with for your specific needs, chatting with a material expert could really help boost performance and keep everything safe and sound.

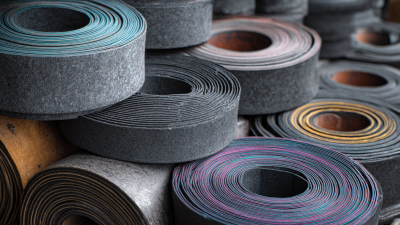

Key Benefits of Viton Strips: Longevity and Durability in Harsh Environments

When it comes to choosing Viton strips for industrial use, it's really about their incredible longevity and toughness—especially in tough, unforgiving environments. Viton, which is a type of fluoroelastomer, is known for resisting extreme temperatures, harsh chemicals, and tough weather conditions. That’s why industries like automotive, aerospace, and manufacturing often gravitate towards it. In fact, according to a report from the International Rubber Study Group, more than 70% of industry leaders actually prefer Viton over regular rubber options for applications exposed to corrosive substances or intense heat. It just proves how dependable this material really is in critical situations.

You can see how long Viton strips last through various industrial tests. Often, they outperform traditional rubbers by up to three times their lifespan. A comparative study from the Rubber Manufacturers Association even showed that Viton stays flexible and intact in temperatures up to 250°C, whereas standard rubber materials really start to break down above 100°C. That kind of durability isn't just about saving money on maintenance—it’s also about safety, reducing the chances of leaks or failures in your systems. So, picking Viton isn’t just about getting good quality; it’s a smart move to keep things running smoothly and reliably for the long haul.

Benefits of Viton Strips in Industrial Applications

Comparative Analysis: Viton vs. Traditional Rubber Strips in Performance and Cost

Lately, there's been a real push in industries to find better materials than the usual rubber strips. You know, something that can handle the tough stuff—think extreme temperatures, chemicals, and all sorts of environmental challenges. That’s where Viton comes into play. It's a fluoropolymer elastomer that’s really holding its own when compared to regular rubber, especially because it resists all those harsh conditions. Companies in sectors like automotive, aerospace, and chemical processing are turning to Viton more and more. The reason? It lasts way longer and cuts down on maintenance costs in the long run, which adds up to some pretty significant savings over time.

Sure, Viton strips tend to cost more upfront than your standard rubber, but honestly, the durability and performance you get make it kinda worth the investment. You end up replacing them less often and still get reliable performance even in tough environments, making it a smart economical choice overall. Plus, with more businesses trying to be eco-friendly and stay compliant with environmental standards, choosing Viton over regular rubber seems like a no-brainer—it's a strategic move that's in line with modern industry trends. All in all, as demand for dependable materials keeps climbing, Viton’s popularity is only going to grow across different sectors. It’s really become an essential part of today’s industrial world.

Viton Strips in High-Temperature Applications: Reliability Metrics and Case Studies

Viton strips are really starting to get noticed for how well they perform in high-temperature industrial settings. If you’ve ever worked with them, you’d know they’re pretty much the go-to for handling extreme heat, harsh chemicals, and aging—stuff that would totally wreck regular materials. For example, in the automotive world, you'll often find Viton strips used in seals and gaskets. They can stand up to crazy temperatures while still holding their shape and function. There are quite a few stories out there showing that machines with Viton parts tend to break down way less and last much longer, which obviously saves a bunch on maintenance and keeps things safer overall.

On top of that, the stats really back up how reliable these strips are. Tests have shown that even when things heat up to over 200°C, Viton strips stay flexible and keep that good sealing action. That’s SO important, especially in industries like aerospace or petrochemicals. There was this one case where a petrochemical plant used Viton in their high-temp valves, and they saw about a 30% drop in downtime. Pretty impressive, right? All these numbers just go to show how effective Viton really is and why so many industries are relying on it to keep things running smoothly and efficiently.

Why Choosing Viton Strips is Essential for Industrial Applications - Viton Strips in High-Temperature Applications: Reliability Metrics and Case Studies

| Application | Temperature Range (°C) | Chemical Resistance | Typical Use Cases | Reliability Rating (1-10) |

|---|---|---|---|---|

| Automotive Fuel Systems | -20 to 200 | Excellent | O-rings, Seals | 9 |

| Industrial Pumps | -10 to 180 | Very Good | Pump Seals | 8 |

| Chemical Processing | 0 to 200 | Excellent | Gaskets, Liners | 9 |

| Aerospace Components | -40 to 300 | Very Good | Seals, Insulators | 10 |

| Oil & Gas Industry | -20 to 180 | Excellent | Sealing Applications | 9 |

The Role of Viton Strips in Meeting Industry Standards and Regulatory Compliance

Viton strips are pretty key when it comes to making sure industrial applications hit those tough industry standards and stay on the right side of regulations. As industries face growing challenges around data privacy and security, turning to materials like Viton has become more of a necessity than ever. These fluoroelastomers are impressive—they resist heat, chemicals, and environmental stresses really well, making them ideal for high-performance sectors like aerospace, automotive, and manufacturing. Basically, they hold up well even under extreme conditions, which lines up with what today's market is demanding: reliable, compliant materials you can count on.

With regulations always changing and getting more complicated, businesses really need to stay on top of compliance to avoid risks and run more smoothly. Viton strips check those boxes—they meet the necessary regulatory standards and help companies manage potential risks linked to choosing the right materials. As Sichuan Fudi New Energy Co., Ltd. keeps pushing forward with new fluoroelastomer innovations, it’s clear they’re dedicated to offering products that not only meet industry standards but also promote a safer, more efficient industrial environment. This way, manufacturers can navigate the confusing landscape of compliance with more confidence and less stress.

Market Trends: The Growing Demand for Viton Strips in Industrial Applications

Lately, you’ve probably noticed that the industrial world is really buzzing about Viton strips. They’re becoming super popular because they perform so well even in tough, demanding environments. You know, places where heat, chemicals, and aggressive fluids are pretty much the norm. Industries like automotive, aerospace, and chemical processing are especially into Viton now because of its incredible resistance to heat and chemical wear and tear. As everyone looks for more reliable, long-lasting materials, Viton strips are pretty much taking center stage as the go-to choice for loads of industrial uses.

If you’re thinking about adding Viton strips to your setup, here are a few tips I’ve learned along the way. First off, make sure to look at the specific environment they’ll be used in—get a good handle on the chemicals involved so you pick the right kind. Next, double-check the temperature range your application needs; that way, you won't end up with a mismatch. And don’t forget about maintenance—regular checks on the wear and tear can really help these things last longer.

Also, with everyone pushing for more sustainable practices these days, Viton’s durability gives companies a real edge. It’s not just about getting the job done; it’s about doing it efficiently and sustainably. Investing in quality materials like Viton isn’t just smart for performance—it lines up with the eco-friendly goals a lot of companies are aiming for these days.

Exploring the Advantages and Applications of Great Chemical Resistance Perfluoroelastomer Compounds in Modern Industries

Perfluoroelastomer compounds, particularly FFKM, have emerged as a cornerstone in various modern industries due to their unparalleled chemical resistance and adaptability. These materials exhibit exceptional resilience against a wide range of aggressive solvents and chemicals while maintaining stability in extreme thermal conditions. With a working temperature range of -20°C to 300°C, FFKM compounds are ideal for applications where resilience is crucial, such as in the aerospace, oil and gas, and pharmaceutical sectors.

FUDI offers three distinct grades of FFKM compounds, each designed to cater to specific industrial needs and working temperatures. The pricing structure reflects the varying thermal performances, making it easier for industries to choose the right compound according to their requirements. This flexibility ensures that businesses can secure the necessary materials without compromising on quality or performance. With a minimum order quantity of just 300 grams, FUDI is poised to meet both small-scale and large-scale manufacturing demands seamlessly.

FAQS

: Viton is a fluoropolymer elastomer known for its superior chemical resistance and stability against extreme temperatures, making it essential for industries such as aerospace, automotive, and chemical manufacturing where material failure can lead to serious consequences.

Viton offers remarkable resistance to extreme temperatures and chemicals, providing a longer service life and reduced maintenance costs compared to traditional rubber strips, despite having a higher initial cost.

Viton can withstand temperatures ranging from -20°F to 425°F, making it suitable for high-temperature applications.

The longevity of Viton strips reduces the need for frequent replacements, leading to cost savings and less downtime for maintenance, which contributes to overall operational efficiency.

To maximize benefits, businesses should ensure proper installation to prevent compression set, conduct regular inspections for wear or degradation, and consult materials experts to select the right grade for specific applications.

The trend toward sustainability is influencing the demand for Viton strips, as their durability and longevity help reduce waste and enhance efficiency, aligning with modern industrial sustainability goals.

The demand for Viton strips is growing particularly in the automotive, aerospace, and chemical processing industries due to their performance in harsh environments.

Companies should assess the specific environmental conditions, ensure compatibility with involved chemicals, evaluate the required temperature range, and establish a maintenance schedule to monitor wear and tear.

Studies show that Viton maintains its properties after prolonged exposure to harsh environments, unlike many other rubber compounds, which contributes to its long-lasting effectiveness.

Choosing Viton over traditional rubber supports compliance with environmental regulations, as higher-quality materials contribute to sustainability and reduced environmental impact in industrial operations.

Conclusion

When it comes to industrial applications, picking the right materials is such a big deal—it really impacts how smoothly things run and how safe everything is. That’s where Viton strips shine. They've got outstanding chemical resistance, making them perfect for tough environments where normal rubber just doesn't cut it. Plus, they're built to last, even in really harsh conditions, which is a huge plus—especially when dealing with high temperatures where reliability is everything. Sure, they might cost a bit more upfront, but over time, their durability and lower maintenance needs make them a smart choice money-wise.

And beyond that, Viton strips are pretty much essential for meeting strict industry standards and regulations, which just helps cement their spot in the market. As Sichuan Fudi New Energy Co., Ltd. keeps pushing the envelope with fluoroelastomer technology, more folks are turning to Viton because it ticks all the boxes—top quality, top performance—no matter the application.

Related Posts

-

7 Reasons Why FKM Is Viton the Best Choice for Your Industrial Needs

-

Understanding Perfluoroelastomer O Rings Benefits and Applications in Global Markets

-

Ultimate Guide to Understanding the Benefits of Fkm Rubber in Industrial Applications

-

Optimizing Performance: Innovative Solutions Using FKM Material Properties

-

The Future of Viton Sponge Rubber in Innovative Industrial Applications

-

What is Oring De Viton Parker and How It Enhances Sealing Performance in Various Industries

Blog Tags:

Charlotte

-

Phone

-

E-mail

-

Whatsapp

-

Top