Exploring FPM Rubber: Key Properties and Market Trends in the High-Performance Sealing Industry

Table of Contents

- Understanding the Unique Properties of FPM Rubber for Sealing Applications

- Evaluating Performance Metrics of FPM Rubber in High-Temperature Environments

- Identifying Market Trends Driving FPM Rubber Adoption in Industry Sectors

- Comparative Analysis of FPM Rubber vs. Alternative Sealing Materials

- Sourcing Strategies for High-Quality FPM Rubber in the Supply Chain

- Future Innovations and Developments in FPM Rubber Technologies for Sealing Solutions

- FAQS

- Conclusion

- Related Posts

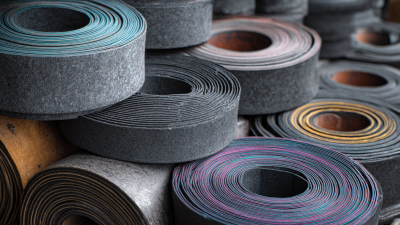

You know, in the world of high-performance sealing, FPM rubber—also called fluoroelastomer—has really been making waves. People are talking about it a lot because of its amazing resistance to chemicals, its ability to handle high temperatures, and its strong mechanical properties. Recent market reports show that the global fluoroelastomer market is expected to grow around 5.2% annually between 2021 and 2026. This growth is mainly driven by rising demand from industries like automotive, aerospace, and oil and gas. Sichuan Fudi New Energy Co., Ltd., which started back in 1998, has been a major player in producing and selling fluoroelastomers and other fluorinated rubber materials for over 20 years. As one of the top manufacturers out there, we offer everything from base fluoroelastomer polymers to FKM/FPM precompounds and fluorosilicone rubber—all designed to meet the tough requirements of different applications. In this article, I’ll walk you through some of the key features of FPM rubber and share a bit about what’s happening in the industry right now, shaping the market as we go.

Understanding the Unique Properties of FPM Rubber for Sealing Applications

You know, fluoroelastomer, or FPM rubber as it's often called, is a pretty amazing material. It’s famous for being super resistant to chemicals and can handle crazy-high temperatures, making it a go-to for tough sealing tasks. According to a recent report from Grand View Research, the worldwide market for fluoroelastomers is projected to hit around USD 2.58 billion by 2025. That’s a pretty big deal, and it’s mainly because industries like automotive, aerospace, and chemicals are really craving this stuff more and more. One of the coolest things about FPM rubber is that it can survive in rough environments—think extreme heat or aggressive chemicals—which is exactly what you need to keep seals lasting longer and working reliably in critical systems.

And it’s not just tough; FPM rubber also does a great job resisting compression set. Basically, it keeps its sealing properties even after being squished for a long time. A study by MarketsandMarkets points out that over 30% of the fluoroelastomer market is taken up by the automotive industry. That’s because FPM is crucial for things like fuel systems and engine seals—where resisting explosive fuel fumes and high temps isn’t optional. Plus, its elasticity and resilience really boost how well sealing solutions perform, matching the high safety and efficiency standards that so many industries are aiming for.

Exploring FPM Rubber: Key Properties and Market Trends in the High-Performance Sealing Industry

| Property | FPM Rubber | Typical Applications | Market Trend |

|---|---|---|---|

| Temperature Resistance | -20°C to 200°C | Automotive seals, Fuel systems | Increasing demand in automotive sector |

| Chemical Resistance | Excellent against oils and fuels | Aerospace, Chemical processing | Growing use in oil and gas extraction |

| Compression Set | Low ( | Industrial machinery, HVAC systems | Increasing preference for durable materials |

| Aging Resistance | Good | Electrical insulation, Seals | Rising demand in electronics |

| Cost | Moderate | General sealing applications | Steady growth in construction industry |

Evaluating Performance Metrics of FPM Rubber in High-Temperature Environments

You know, FPM rubber is really making waves lately. It's praised for being super stable when it comes to heat and resistant to chemicals, which is pretty impressive. Because of that, it's becoming a go-to material especially in tough environments—think oil and gas sites—where things get seriously hot and harsh. The performance stats are pretty clear: FPM can handle extreme temperatures without breaking a sweat. That’s why it’s perfect for sealing parts that are constantly exposed to hydrocarbon fluids. Oh, and there’s some cool stuff happening too — for example, recent innovations like wrapping up fancy accelerometers with epoxy and fluoroelastomer are just the tip of the iceberg. It’s all about using smart materials to make sure our gadgets last longer and perform better, even when conditions are rough.

Thanks to FPM rubber’s ability to stay solid under high heat, crucial components, like sensors, keep working reliably without falling apart. That's a big deal for condition monitoring systems, which need accurate readings to keep things running smoothly. As more industries seek high-performance seals that can handle the heat and chemicals, it’s more important than ever to check out how well FPM rubber actually performs. Its toughness against thermal and chemical stress really puts it ahead of the pack, making it the top choice for those demanding environments where nothing but the best will do.

Identifying Market Trends Driving FPM Rubber Adoption in Industry Sectors

You know, FPM rubber, also called fluorocarbon rubber, is really starting to make waves across different industries. People are loving it because it’s super resistant to chemicals, can handle high temperatures, and doesn’t age easily. For industries like automotive, aerospace, and pharmaceuticals, it’s become a go-to choice for sealing applications. This shift is partly driven by stricter regulations and the push for better product performance. Plus, more companies are leaning towards eco-friendly materials, and FPM fits right in – it’s durable, reliable, and outperforms some traditional options out there.

On top of that, the focus on innovation and tech advancements in manufacturing is really pushing the market for FPM rubber forward. Companies are pouring resources into R&D to come up with smarter formulations and better processing methods, which not only boost the material’s qualities but also help cut down production costs. The automotive industry’s growth—especially with the rise of electric vehicles—is creating a big demand for sealing solutions that can handle extreme conditions. Overall, as industries keep pushing safety and efficiency, FPM rubber seems perfectly positioned to meet these new challenges and market needs.

Comparative Analysis of FPM Rubber vs. Alternative Sealing Materials

FPM rubber is pretty amazing when it comes to resisting heat, chemicals, and aging. That’s why it really stands out in the world of high-performance sealing solutions. If you look at other materials like silicone, EPDM, or nitrile rubber, FPM tends to outlast and outperform them in tough, demanding environments. For example, silicone might be more flexible and handle high temperatures being no problem, but it often falls short on chemical resistance. And while EPDM does a good job with water and steam, it just can’t match FPM’s ability to handle a wider range of chemicals and stay durable over time.

When you're choosing a sealing material, it’s really worth thinking about the specific conditions it’ll face—like what kind of chemicals it’ll be exposed to or the temperatures involved. Doing a quick compatibility check upfront can save a lot of hassle down the road, like premature failures or costly maintenance.

Nitrile rubber is another option that folks often go for because it resists oil well. But the thing is, it doesn’t do so great with high heat or ozone, which can be a problem in many automotive and industrial settings. FPM, on the other hand, keeps its integrity in those scenarios, making it a solid choice wherever performance counts.

Really understanding the pros and cons of each material helps manufacturers make smarter choices, leading to more reliable and efficient sealing solutions. And a little tip—stay in the loop with the latest trends and breakthroughs in materials science. It can make a big difference in how long your products last and how well they perform over time.

Sourcing Strategies for High-Quality FPM Rubber in the Supply Chain

Finding high-quality FPM rubber is really important for companies in the high-performance sealing business—especially nowadays, with everyone needing tougher materials that can handle extreme conditions without breaking a sweat. For brands like Sichuan Fudi New Energy Co., Ltd., which has been a top player in making fluoroelastomers for over twenty years, understanding how to choose the right sourcing strategies can give them a real edge over the competition.

When you're on the hunt for FPM rubber, it's not just about picking any supplier—look for ones who deliver top-notch materials and also stick to industry standards. Building solid relationships with your suppliers can really pay off—think better prices, more consistent quality, and reliable delivery times. Plus, it's super important to check out their manufacturing capabilities, certifications, and whether they can meet the specific material specs you need for different projects.

**Pro tip:** Always ask for samples before placing big orders—this way, you can really test how the material performs in your particular application. Keeping an eye on market trends is also a good idea because it helps you spot new suppliers and innovative materials that might give you better performance or save some cash. And don’t forget—attending industry events and forums can be a goldmine for making valuable connections and picking up tips on the best sourcing practices out there.

FPM Rubber Demand and Market Trends (2021-2023)

This chart illustrates the demand for FPM rubber in the high-performance sealing industry over the last three years, highlighting key growth trends and shifts in sourcing strategies.

Future Innovations and Developments in FPM Rubber Technologies for Sealing Solutions

Looking ahead, the future of FPM rubber tech in sealing solutions is pretty exciting, with lots of room for major improvements. There’s a surge in interest around developing new and better FPM compounds that can handle higher temperatures and harsh chemicals—especially since many industries like automotive, aerospace, and oil & gas are pushing for more durable, reliable seals for extreme conditions. As these sectors grow, so does the need for sealing materials that won’t quit when faced with tough media or super hot environments. This means R&D efforts are going into overdrive to keep up.

On top of that, new manufacturing methods—think 3D printing and next-gen extrusion—are really shaking things up. These tech advances make it possible to customize parts more easily, whip up prototypes faster, and cut down on material waste, which is a big win for costs. Plus, being able to craft complex shapes tailored to specific needs means sealing devices are getting better at their jobs. All of this gives manufacturers a real leg up, making their sealing solutions more competitive and high-performing in the market.

FAQS

: FPM rubber, or fluoroelastomer, is a specialized material known for its exceptional chemical resistance and thermal stability, making it ideal for demanding sealing applications.

Industries such as automotive, aerospace, and chemicals are significantly driving the demand for FPM rubber, particularly for sealing applications.

FPM rubber is durable, has excellent compression set resistance, and maintains its sealing properties over prolonged periods, while also being able to withstand extreme temperatures and aggressive chemicals.

FPM rubber excels in high-temperature environments, making it suitable for sealing solutions that endure constant exposure to hydrocarbon fluids, particularly in the oil and gas industry.

Future advancements include enhanced synthesis methods for improved thermal stability and chemical resistance, as well as cutting-edge manufacturing techniques like 3D printing for greater customization.

The compression set resistance is crucial because it allows FPM rubber to maintain effective sealing properties over long periods, ensuring reliability in critical applications.

FPM rubber accounts for over 30% of the fluoroelastomers market in the automotive sector, used primarily in fuel systems and engine seals due to its resistance to high temperatures and fuel mixtures.

Innovations such as advanced extrusion methods and 3D printing will enhance the production of FPM rubber components, allowing for customization, faster prototyping, and reduced material waste.

Performance metrics indicate that FPM rubber maintains its integrity and functionality under high thermal and chemical stress, making it a leading choice for high-performance sealing solutions.

The global fluoroelastomer market is expected to reach USD 2.58 billion by 2025, highlighting the growing demand for FPM rubber in various industries.

Conclusion

So, this article really digs into what makes FPM rubber stand out in the market, especially highlighting its unique features that make it perfect for sealing jobs. You know, FPM rubber is pretty amazing when it comes to resisting crazy-high temperatures and harsh chemicals—that’s a game-changer for tough industrial sealing tasks. When they compare its performance to other materials, it’s pretty clear that FPM comes out on top, especially in demanding environments.

Plus, the article touches on the current market trends that's making more folks jump on the FPM bandwagon — mainly the rise in demand for top-notch sealing solutions. It also gives some handy tips on how to source good-quality FPM rubber, so manufacturers can keep up with what’s expected out there. And, of course, it looks ahead at future tech and innovations in FPM rubber that could bring even better sealing performance and reliability for all sorts of applications. Pretty exciting stuff, honestly.

Related Posts

-

How to Choose the Right Fpm Gasket Material for Your Industrial Applications

-

Ultimate Guide to Understanding the Benefits of Fkm Rubber in Industrial Applications

-

The Ultimate Guide to Selecting Fluoroelastomer Sheets: Key Features and Industry Insights

-

Why Choosing Viton Strips is Essential for Industrial Applications

-

Unlocking the Benefits of Fluoroelastomer Strips in Modern Industrial Applications

-

How to Choose the Right Viton Material for Your Industrial Needs

Blog Tags:

Charlotte

-

Phone

-

E-mail

-

Whatsapp

-

Top