Exploring the Impact of Oring Box Viton on Industry Growth at the 138th Canton Fair 2025

Table of Contents

- Exploring the Role of Viton O-Rings in the Manufacturing Sector at the Canton Fair 2025

- Analyzing the Growth of the Rubber Sealing Industry Due to Viton O-Rings Adoption

- Assessing the Market Demand for High-Performance Sealing Solutions at the 138th Canton Fair

- Impact of Viton O-Rings on Sustainable Manufacturing Practices in Various Industries

- Evaluating Innovations in Viton O-Ring Production Technologies Highlighted at the Fair

- Exploring the Durability and Applications of Alkali Steam Resistance FEPM Aflas Compound in Industrial Settings

- FAQS

- Conclusion

- Related Posts

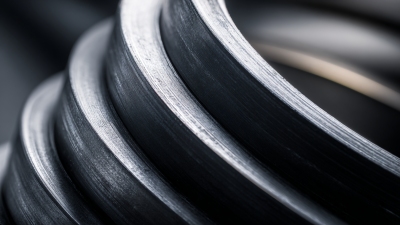

Hey, did you know the 138th Canton Fair coming up in 2025 is such a big deal? It’s a perfect chance to see how the Oring Box Viton is really shaking things up across various industries—especially when it comes to next-level sealing tech. Sichuan Fudi New Energy Co., Ltd., a major player with over 20 years of experience in making fluoroelastomers, is right there at the forefront of this innovation. Recent market forecasts suggest that the global fluoroelastomers market could hit around $3 billion by 2025, thanks to their incredible resistance to chemicals and high-temperature stability. Adding Oring Box Viton into the mix is expected to boost the performance of industrial applications, from cars to aerospace—fancy, huh? This just shows how important cutting-edge sealing solutions like Oring Box Viton really are for driving industrial growth, especially now, with all the rapid changes in the economy and the increasing demand for better materials that are sustainable and perform better.

Exploring the Role of Viton O-Rings in the Manufacturing Sector at the Canton Fair 2025

Hey there! So, the upcoming 138th Canton Fair in 2025 is gonna be a big deal, especially showcasing how Viton O-Rings are really shaking things up in manufacturing. If you’re not familiar, Viton’s that go-to material known for resisting crazy heat and chemicals—it's basically what everyone’s turning to when they want something durable and trustworthy for sealing stuff. As industries push harder for efficiency and being eco-friendly, using Viton O-Rings seems to give companies a real edge—think fewer maintenance headaches and better overall performance.

For manufacturers thinking about giving Viton O-Rings a shot, my best tip? Take a moment to check if they’re chemically compatible with your specific environment. Also, get a clear idea of the temperatures and pressures those O-Rings need to handle—that way, you pick the right specs from the get-go. And honestly, the Canton Fair is a fantastic chance to meet with suppliers face-to-face and learn about the latest and greatest in sealing technology. It’s a chance to stay ahead of the game.

Plus, attending isn’t just about buying stuff. It's a great way to network with industry pros and discover new tech that could totally change how you work. Definitely check out the workshops and talks focused on best practices for Viton O-Rings—that’s where you’ll pick up tips to boost your products’ reliability and, in the long run, grow your business too.

Analyzing the Growth of the Rubber Sealing Industry Due to Viton O-Rings Adoption

So, you know how Viton O-Rings are really making waves in the rubber sealing world? I mean, we saw a lot of buzz at the 138th Canton Fair back in 2025. Viton is pretty much loved because it stands up really well against heat, chemicals, and stuff like wear and tear. It’s become the go-to material for all sorts of industrial use cases. I recently came across a report from Research and Markets that says the rubber sealing industry is expected to grow pretty steadily—around 5.4% each year from 2022 to 2030. And honestly, Viton O-Rings are a big part of that growth because they just perform so much better.

In industries like automotive, aerospace, and chemical processing, these Viton O-Rings are helping companies come up with sealing solutions that don’t just prevent leaks but also last longer. I also read a study from Grand View Research that mentioned the global market for O-Rings was worth about $4.25 billion in 2021. And it’s not slowing down—more industries are shifting towards high-performance sealing materials. What’s really interesting is how Viton has become such a key player in this shift, reflecting a bigger move towards specialty elastomers that can meet pretty tough standards. As more manufacturers realize the benefits of Viton O-Rings, I think we’re on the verge of some pretty exciting growth and tech advancements in the rubber sealing world.

Assessing the Market Demand for High-Performance Sealing Solutions at the 138th Canton Fair

The 138th Canton Fair in 2025 is shaping up to be pretty exciting, especially because it’s going to shine a spotlight on the rising demand for really high-performance sealing solutions. You know, with the advent of new materials like Oring Box Viton, things are getting interesting. As industries push for more efficiency and dependability, the market for top-quality seals is expected to grow quite a bit. I read somewhere that the global industrial sealing market was worth around $26.6 billion in 2023, and with automation and smarter manufacturing tech catching on, that number’s only going up.

Lately, the trends in robotics just add fuel to the fire. The worldwide market for industrial robots has hit a staggering $16.5 billion—amazing, right? This huge jump is mainly because everyone wants systems that are precise and reliable. And let’s be honest, fancy sealing solutions are a big deal in making sure these machines last and perform well—especially in critical environments where you really don't want anything going wrong.

What’s also interesting is how these trade fairs keep highlighting innovation. It’s clear that industries are leaning more and more towards integrating advanced materials into their processes. As things keep evolving, it’s pretty certain that the demand for high-performance seals like Oring Box Viton will skyrocket. So, if you’re into this stuff, the upcoming Canton Fair is definitely one event you won’t want to miss—it’s a huge deal for anyone involved in this ever-changing market.

Impact of Viton O-Rings on Sustainable Manufacturing Practices in Various Industries

You know, Viton O-rings are really gaining traction in a bunch of industries these days. Whether it’s automotive, chemical, or semiconductor manufacturing, these little seals are playing a bigger role in helping companies go greener. They’re known for being tough and resistant to harsh chemicals, which means factories can stay efficient without putting too much strain on the environment. Honestly, using materials like Viton is a pretty big step forward when it comes to sustainable manufacturing—it's like doing your part while keeping things running smoothly.

On a global scale, the market for O-rings—especially those made from fluoroelastomers like Viton—is booming. They’re used in everything from sealing semiconductors to parts in cars, and the demand isn’t slowing down anytime soon. If you’re trying to get a good grasp of this market, it helps to understand the size, share, and potential growth—looking at factors like what type of material is used and where it’s applied gives you a better overall picture.

Evaluating Innovations in Viton O-Ring Production Technologies Highlighted at the Fair

The 138th Canton Fair in 2025 really highlighted how much the technology behind Viton O-rings has come along — you could see some pretty exciting advances in sealing tech. I read in a recent MarketsandMarkets report that the global market for O-rings is expected to hit about $8.6 billion by 2026, growing at around 5.6% CAGR from 2021. A big reason? Innovations like better manufacturing methods and new high-performance materials, especially advanced Viton formulas that resist extreme temperatures and harsh chemicals way better than before.

What caught my eye at the fair were the new production techniques using automation and highly precise molding. These upgrades not only make the O-rings last longer and perform better, but they also help cut down costs and speed up production. Plus, it was pretty clear that sustainability is getting serious attention — a lot of companies showcased eco-friendly materials and greener manufacturing processes that cut waste and save energy.

When you're shopping around for O-ring suppliers, my advice? Look for those really committed to innovation and green practices. Companies that invest in modern tech are more likely to offer products that perform well and last longer. And don’t forget to check their certifications and standards; you want materials that are up to the mark for your specific needs.

Impact of O-Ring Box Viton on Industry Growth at the 138th Canton Fair 2025

This chart shows the projected growth in demand for Viton O-Ring products from 2023 to 2025 based on innovations presented at the 138th Canton Fair. The data reflects industrial applications, automotive needs, and chemical resistance requirements.

Exploring the Durability and Applications of Alkali Steam Resistance FEPM Aflas Compound in Industrial Settings

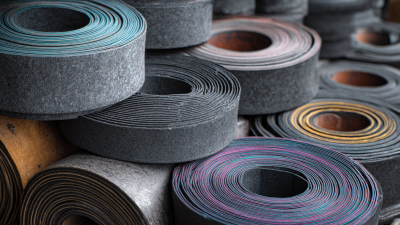

The Aflas FEPM compound stands out in industrial settings for its remarkable properties, particularly its durability against alkalis and acids. This unique resilience makes it an indispensable material in environments where chemical exposure is inevitable, ensuring longevity and reliability in performance. Aflas FEPM not only excels in chemical resistance but also boasts superior electrical insulation and impermeability, making it ideal for applications in industries such as automotive, aerospace, and chemical processing.

Customization is another key feature of the Aflas FEPM raw polymer. Its hardness can be tailored to meet specific operational needs, allowing it to adapt to various applications without compromising its integrity. Whether utilized in seals, gaskets, or protective coatings, Aflas FEPM provides a robust solution that meets the diverse requirements of industrial applications. Its ability to withstand extreme conditions without degradation further solidifies its position as a leading choice for engineers and manufacturers seeking dependable materials for challenging environments.

FAQS

: The adoption of Viton O-Rings, known for their exceptional resistance to heat, chemicals, and wear, is a major factor driving the growth of the rubber sealing industry.

The rubber sealing industry is projected to grow at a CAGR of 5.4% from 2022 to 2030.

The global O-Rings market was valued at approximately $4.25 billion in 2021 and is expected to expand as industries increasingly seek high-performance sealing materials.

The adoption of Viton O-Rings is particularly beneficial in the automotive, aerospace, and chemical processing sectors.

The global industrial sealing market was valued at approximately $26.6 billion in 2023.

Rising automation increases the demand for high-quality sealing solutions, as they are crucial for ensuring the longevity and effectiveness of automated systems.

The global market value of industrial robot installations has reached approximately $16.5 billion, highlighting the need for reliable sealing solutions in precision-demanding environments.

The 138th Canton Fair is expected to spotlight the growing demand for high-performance sealing solutions and showcase advancements in materials like Oring Box Viton.

Recent trends indicate a shift toward integrating advanced materials into manufacturing processes, reflecting an increasing emphasis on innovation and performance in sealing products.

The integration of advanced materials like Viton O-Rings is essential for improving sealing solutions, which reduce leakage risk and enhance the durability of products in various industrial applications.

Conclusion

So, I came across this article titled "Exploring the Impact of Oring Box Viton on Industry Growth at the 138th Canton Fair 2025," and honestly, it’s pretty interesting. It talks about how Viton O-Rings are playing a pretty big role in boosting the manufacturing world. Basically, as more companies look for top-notch sealing solutions, Viton O-Rings are really taking center stage, driving growth in the rubber sealing scene. The article also dives into what all these innovations mean for more sustainable manufacturing practices across different industries — pretty cool stuff, especially with all the advanced Viton O-Ring tech they showcased at the fair.

On a related note, Sichuan Fudi New Energy Co., Ltd., a major player in the fluoroelastomer game, is well-positioned to gain from these trends. They've been around for over 20 years, and their focus on quality products — including their Oring Box Viton components — really shows in how they’re ready to meet the needs of manufacturers looking for reliable and eco-friendly sealing solutions. It’s a fascinating look at how innovation and experience come together in this industry.

Related Posts

-

The Future of Viton Sponge Rubber in Innovative Industrial Applications

-

Why Choosing Viton Strips is Essential for Industrial Applications

-

How to Choose the Right Viton Sheet for Your Industrial Needs

-

How to Choose the Right Fpm Gasket Material for Your Industrial Applications

-

Optimizing Performance: Innovative Solutions Using FKM Material Properties

-

Ultimate Guide to Understanding the Benefits of Fkm Rubber in Industrial Applications

Blog Tags:

Eleanor

-

Phone

-

E-mail

-

Whatsapp

-

Top