Optimizing Performance: Innovative Solutions Using FKM Material Properties

Table of Contents

- Understanding FKM Material Properties and Their Benefits

- Exploring Alternative Materials for Enhanced Performance

- Design Considerations: Selecting the Right FKM Alternative

- Real-world Applications of FKM Alternatives in Various Industries

- Performance Comparison: FKM vs. Traditional Materials

- Future Trends in FKM Material Development and Innovation

- Exploring the Benefits and Applications of FKM Fluoroelastomer Compounds for Molding Purposes

- FAQS

- Conclusion

- Related Posts

Hey there! You know, in today’s fast-changing world of engineering materials, how well a component performs really depends a lot on the unique traits of FKM materials. I recently came across a report from MarketsandMarkets, and it says the global market for fluoroelastomers is expected to hit around $1.03 billion by 2025 — all thanks to their awesome chemical resistance and ability to handle high temperatures.

Sichuan Fudi New Energy Co., Ltd., has been a key player in this space since way back in 1998. They’ve been into making and selling fluoroelastomers and other fluorinated rubbers for more than 20 years now. Their expertise includes a wide range of products — from base polymers to FKM/FPM precompounds, and even curing agents — all designed to meet different needs across industries.

In this article, we’ll dig into some of the top strategies for using FKM’s unique properties to boost performance and drive innovation in various sectors.

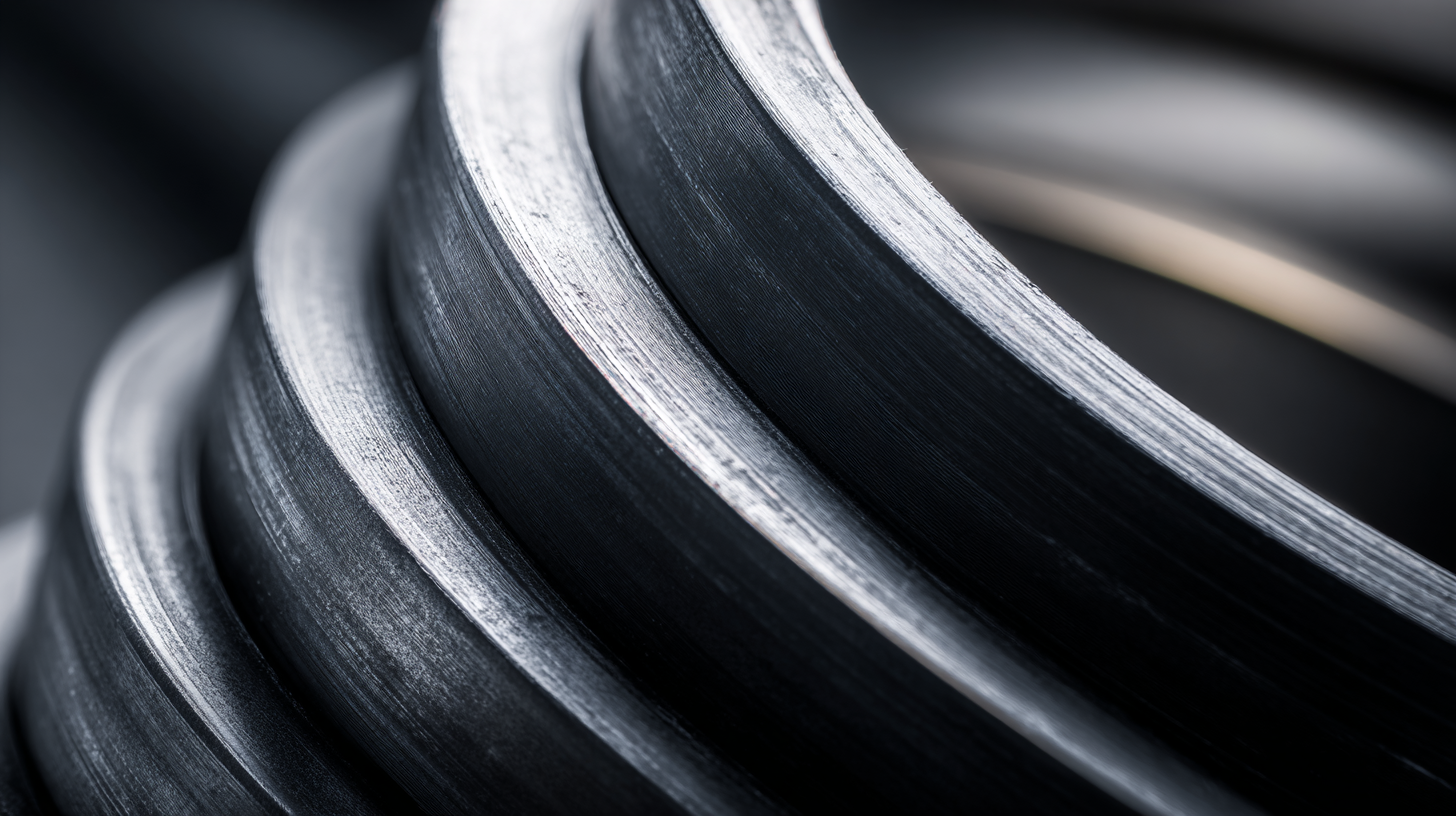

Understanding FKM Material Properties and Their Benefits

Hey, have you heard about FKM (that’s fluoroelastomer)? It’s been getting a lot of buzz lately because of its really impressive properties. These materials are super tough—they resist heat, chemicals, and weathering way better than your average elastomers. That makes them perfect for some pretty demanding environments. You’ll mostly see industries like automotive, aerospace, and oil and gas turning to FKM to boost performance and make things more reliable. Especially now, with everyone looking for lightweight yet durable stuff—like in electric vehicles—FKM’s unique qualities open up loads of new possibilities for designing better components.

And get this, as the market for specialty elastomers keeps growing, experts expect the high-performance plastics used in semiconductors to blow up too—projected to hit around $6.12 billion by 2033. All this just shows how vital advanced materials like FKM really are in pushing tech forward and helping companies run smoother and last longer. The ones who are making the most of FKM’s amazing features are probably going to be ahead of the game, ready to meet industry needs for products that not only perform really well but also stand the test of time.

Exploring Alternative Materials for Enhanced Performance

When it comes to boosting performance across different fields, exploring new materials really opens up a bunch of exciting possibilities. For example, developing bio-based shape-memory polyurethane polymers not only showcases some pretty innovative properties but also puts a spotlight on sustainability. These smart materials are proving to be super useful, especially in biomedical applications, showing that eco-friendly solutions can work hand-in-hand with high functionality.

On top of that, recent progress in geopolymer concrete is pretty impressive, highlighting how recycled materials can play a big role in construction. By adding recycled aggregates and using eco-friendly activators like sodium silicate made from industrial waste, we can craft high-performance concrete that checks all the boxes—strength, safety, and being good for the planet. This not only helps cut down on waste but also actually improves the mechanical properties of building materials, pushing us toward more sustainable development.

And then there’s the rise of lightweight composites—especially those made with recycled carbon fiber—which could totally shake things up in industries like transportation. Using these innovative materials means not only better performance but also a smaller ecological footprint. It’s pretty amazing how alternative materials are really transforming modern engineering and construction, making them more sustainable and efficient all at once.

Design Considerations: Selecting the Right FKM Alternative

When you're trying to pick the right FKM alternative to boost performance, there are a bunch of design points to keep in mind. You see, FKM, also known as Fluoroelastomer, is pretty renowned for its incredible resistance to heat, chemicals, and wear and tear, so it's often the go-to in tough environments. But here’s the thing—not every application needs the same level of performance. That's why it’s really important to get a good handle on the different properties of various FKM options out there. Things like temperature limits, how well it fights off chemicals, and its mechanical strength all come into play, making sure the material you pick actually fits the bill for what you're using it for.

And don’t forget about processing—it's a big deal too. Different FKM formulas can vary quite a bit when it comes to how easy they are to work with or how they cure, which can affect both your production process and costs. It's also smart to think about the environment where the material will be used and what kind of failures might happen—that can really influence your choice. When you take all these things into account and pick the best FKM alternative, you’re more likely to get a product that’s reliable, performs well, and still keeps things budget-friendly.

Real-world Applications of FKM Alternatives in Various Industries

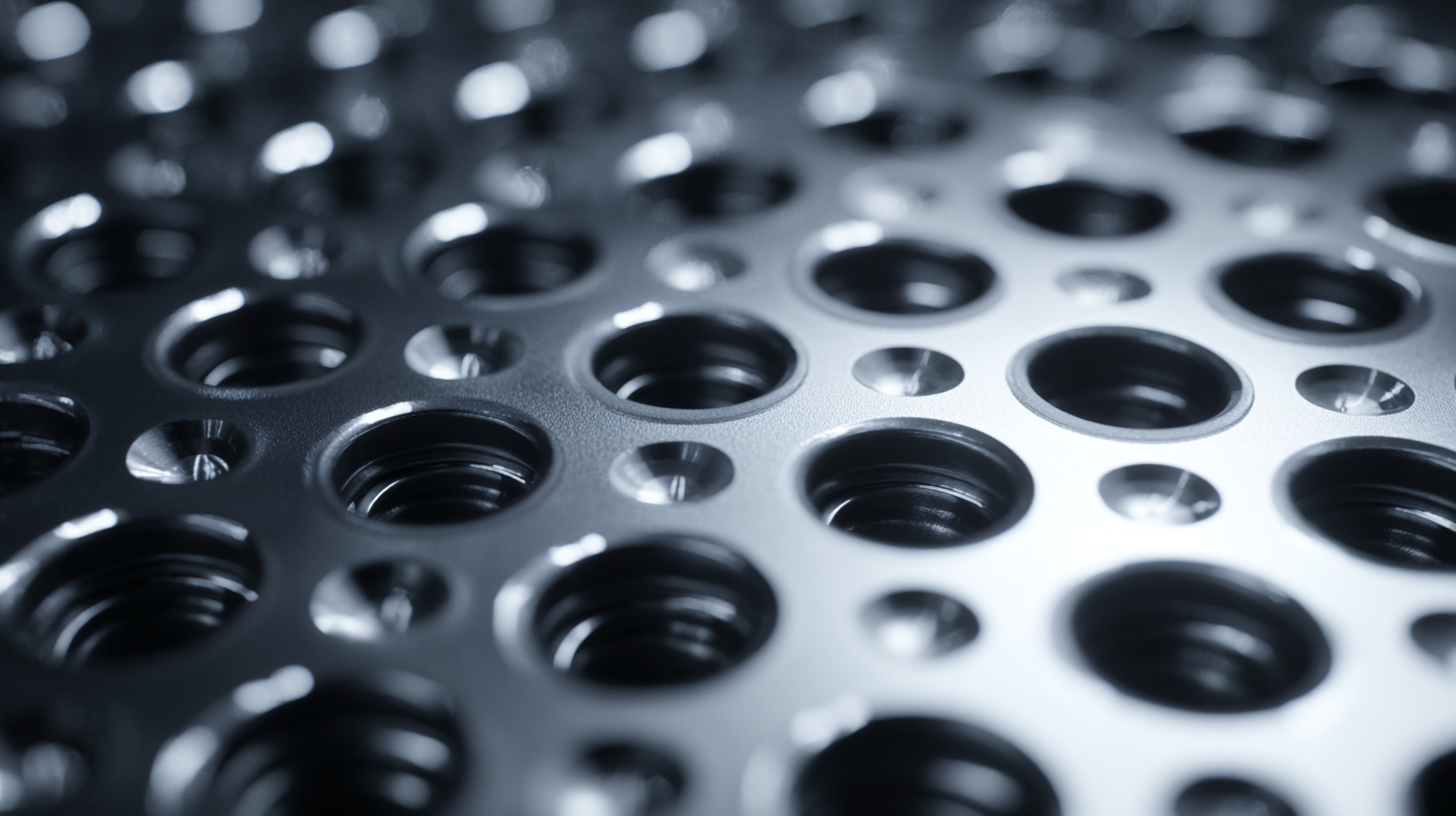

You know, in different industries, the special qualities of FKM, or fluoroelastomer, materials have really helped come up with some pretty clever solutions to improve performance. Take the auto industry, for example — they rely on FKM-based seals and gaskets to keep things running smoothly, even under super tough conditions like crazy-high temperatures and harsh chemicals. These seals keep everything reliable and durable, which is a big deal. And get this, manufacturers are on the lookout for alternatives to the traditional FKM — ones that can handle the same hot and chemical challenges but cost a lot less. That way, companies can make their products last longer without breaking the bank, you know?

Then there’s the oil and gas world, where stuff gets really rough – the materials they extract can be pretty corrosive. That’s where strong sealing solutions come into play. Thanks to newer, improved FKM alternatives, companies can stay efficient even in super high-pressure, chemical-rich environments. These materials are built to resist all sorts of chemicals and extreme conditions, which is super important for safety and smooth operations. As industries keep moving forward, it’s pretty clear that the focus on these advanced materials — whether FKM or its alternatives — really shows how vital it is to have tough, performance-focused solutions that fit today’s manufacturing needs.

Performance Comparison: FKM vs. Traditional Materials

When it comes to high-performance materials, fluoroelastomer, or FKM for short, really stands out thanks to some pretty impressive properties — especially when you compare it to more traditional elastomers. Adding in some clever coagents like triallyl isocyanurate (TAIC) and trimethallyl isocyanurate (TMAIC) can boost FKM’s qualities even more, especially when it's cured with peroxide. This kind of innovation has led to the development of FKM/EFEP thermoplastic vulcanizates (TPV), which aren’t just resistant to heat and oils — they also deliver excellent gas barrier features and are recyclable, which is a big plus these days.

If you're wondering how FKM stacks up against regular materials, it’s mainly because of its stellar chemical and heat resistance. That’s largely thanks to the strong carbon-fluorine (CF) bonds. These bonds give FKM a real edge — it can hold up in rough environments where other elastomers might struggle. The rapidly growing interest in FTPVs shows that we’re moving toward smarter elastomer solutions that can handle tough demands while also being kinder to the planet with good recyclability.

**Quick tip:** When you're picking materials for tough, high-performance stuff, it's super important to think about the specific environment they'll face. Using FKM’s unique properties can really boost how long your products last. Also, make sure your processing techniques align well with these advanced elastomer formulations to get the most out of them. And don’t forget — working with experienced suppliers like Sichuan Fudi New Energy Co., Ltd. can give you access to some of the latest fluoroelastomer innovations out there.

Optimizing Performance: Innovative Solutions Using FKM Material Properties - Performance Comparison: FKM vs. Traditional Materials

| Property | FKM Material | Traditional Material | Performance Difference |

|---|---|---|---|

| Temperature Resistance | -40 to 250 °C | -20 to 120 °C | Higher range by 130 °C |

| Chemical Resistance | Excellent | Good | Superior resistance |

| Aging Resistance | Very Good | Moderate | Longer lifespan |

| Compression Set | Low (10-15%) | High (20-30%) | Less permanent deformation |

| Tensile Strength | 20-25 MPa | 10-15 MPa | Stronger by up to 15 MPa |

Future Trends in FKM Material Development and Innovation

Developing FKM, or fluoroelastomers, really marks a big step forward when it comes to high-performance materials. You know how industries are always pushing for stuff that can handle really tough conditions? Well, FKM fits right into that, thanks to its amazing resistance to heat, chemicals, and aging. It's pretty much a go-to for some pretty cutting-edge applications. Looking ahead, I think we’ll see ongoing efforts to make these properties even better and to find new uses in tech-heavy areas like semiconductors, aerospace, and renewables.

On a broader scale, moving toward FKM kind of mirrors a bigger trend we’re seeing in materials science — going for high-performance membranes and smart composites that pack multiple benefits into one. The game-changer? Advanced tech and clever manufacturing techniques. Honestly, as we push further into the future, I believe the combo of innovative science and real-world industry needs will open doors to breakthroughs that could totally change industry standards and expectations. And at the heart of it all, FKM will keep playing a major role in driving innovation forward.

Exploring the Benefits and Applications of FKM Fluoroelastomer Compounds for Molding Purposes

Fluoroelastomer compounds, particularly FKM, have gained significant traction in various molding applications due to their unique characteristics and benefits. These compounds consist of a blend of FKM raw gum, crosslinkers, and fillers, which creates a user-friendly material ready for immediate use. With a hardness range from 50 to 90 Shore A, FKM compounds provide versatility suited for demanding environments, making them ideal for industries such as automotive, chemical processing, and aerospace.

One of the standout features of FKM compounds is their tailor-made color options, which allow manufacturers to create visually appealing products while maintaining the functionality required in high-performance applications. According to a recent industry analysis, the global demand for fluoroelastomers is projected to reach 800 million USD by 2025, reflecting a CAGR of 5% from 2020. This escalating demand underscores the relevance of customizability in FKM products, enabling businesses to cater to specific market needs and consumer preferences.

In addition to their performance capabilities, FKM compounds also have a notable shelf life, ranging from six to twelve months. This longevity is crucial for manufacturers looking to maintain production efficiency and reduce waste. The robust nature of FKM materials not only enhances durability but also ensures they can withstand extreme temperatures and chemical exposure, solidifying their position as a preferred choice in innovative molding solutions across various sectors.

FAQS

: Bio-based shape-memory polyurethane polymers are innovative materials that showcase unique properties and emphasize sustainability, particularly in biomedical applications.

Geopolymer concrete utilizes recycled materials and eco-friendly activators to create high-performance concrete that meets structural and environmental standards, reducing waste and enhancing mechanical properties.

Lightweight composites utilizing recycled carbon fiber can significantly improve performance and reduce ecological footprints, potentially revolutionizing industries such as transportation.

FKM, or Fluoroelastomer, is a material known for its exceptional resistance to heat, chemicals, and abrasion, making it crucial for applications in harsh environments.

Key factors include temperature range, chemical compatibility, mechanical strength, processing characteristics, manufacturing efficiency, and operational environment.

Different FKM formulations have varying manufacturability and curing characteristics, which can influence production efficiency and overall costs.

Yes, alternative materials like bio-based polymers and recycled composites can achieve high performance while aligning with sustainability goals.

Recycling can provide materials for construction that not only minimize waste but also enhance the performance of concrete and other building materials.

Understanding potential failure modes helps ensure that the selected material will be reliable under the expected operational conditions, enhancing safety and performance.

Carefully selecting materials based on design considerations improves product reliability and performance while maintaining cost-effectiveness for manufacturers.

Conclusion

When you’re looking to boost performance in different industries, it’s pretty crucial to get a good grip on FKM material properties. These materials are known for their impressive resistance to chemicals, high thermal stability, and strong mechanical features — which means they’ve got some serious perks over the usual stuff. In this blog, I’ll walk you through some of the coolest innovations that come from these properties, and I’ll also mention a few alternative materials that might take performance even further. Picking the right FKM substitute isn’t just guesswork — it takes careful planning to make sure whatever you choose fits your specific needs.

If you look at real-world use cases, you’ll see just how versatile FKM alternatives can be across industries like automotive and aerospace — they really shine in tough environments. Comparing FKM to traditional options, it’s clear that FKM often comes out on top, especially when conditions are demanding. And as we look ahead, new developments in FKM technology are opening doors to exciting innovations. It’s an exciting time for fluorinated rubber materials, and they’re definitely leading the charge in this evolving field.

Blog Tags:

Oliver

-

Phone

-

E-mail

-

Whatsapp

-

Top