What is Oring De Viton Parker and How It Enhances Sealing Performance in Various Industries

Table of Contents

- Understanding Oring De Viton Parker: Composition and Characteristics

- Key Advantages of Oring De Viton Parker in Industrial Applications

- How Oring De Viton Parker Improves Sealing Performance

- Comparative Analysis: Oring De Viton Parker vs. Traditional Sealing Solutions

- Industry-Specific Applications of Oring De Viton Parker

- Maintenance Tips for Maximizing the Lifespan of Oring De Viton Parker

- Enhancing Industrial Applications with Peroxide Curable FKM Raw Polymer: Benefits and Innovations

- FAQS

- Conclusion

- Related Posts

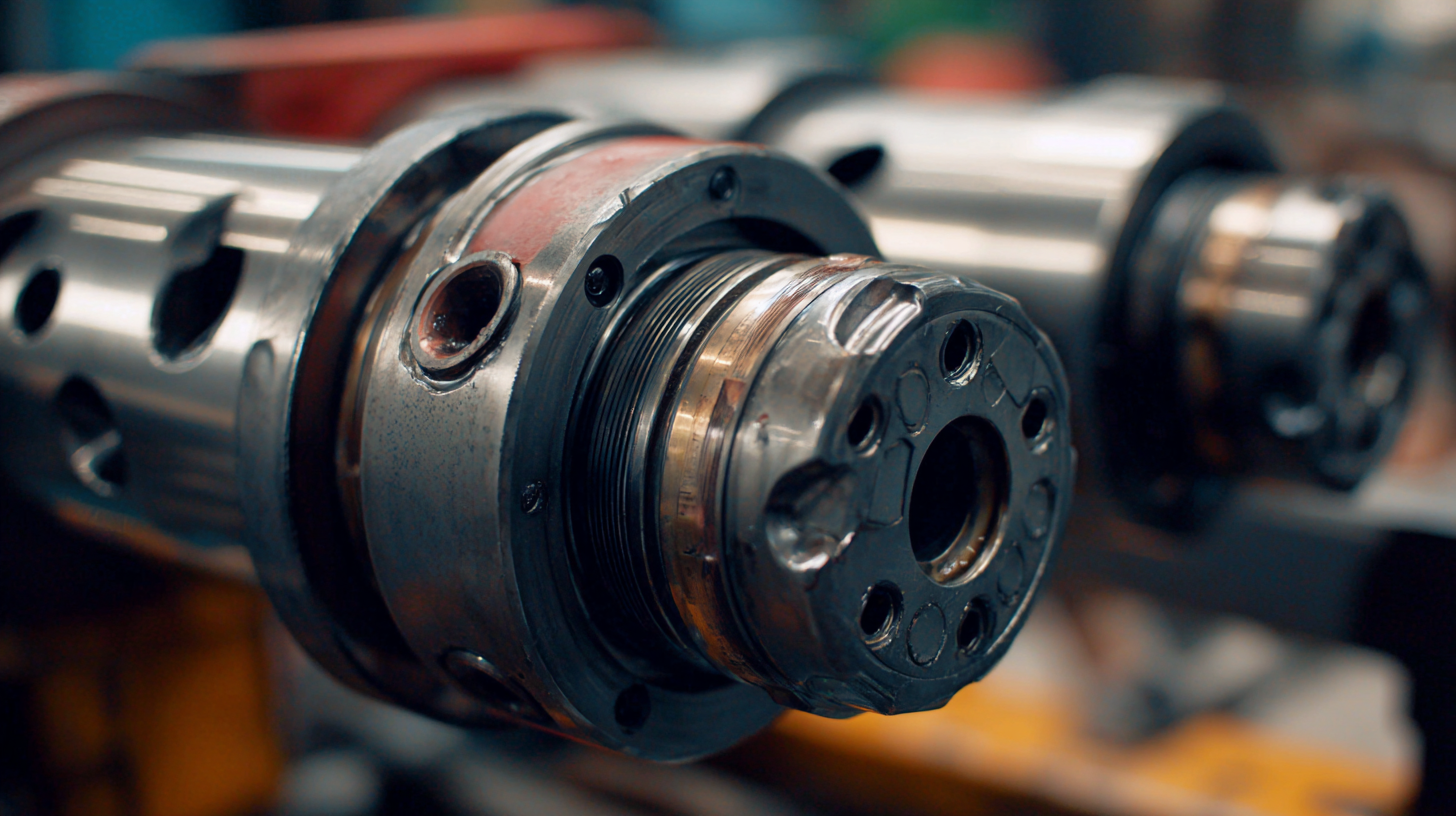

In today's super-fast-paced industrial world, finding reliable sealing solutions is more important than ever. One product that's really making waves is the Oring De Viton Parker. It's praised for its top-notch sealing performance in a bunch of different applications. As industries push for materials that can handle crazy temperatures, tough chemicals, and rough environments, the Oring De Viton Parker actually stands out as a pretty versatile choice. Here at Sichuan Fudi New Energy Co., Ltd., we’ve been around since 1998, focusing on the production and sales of fluoroelastomers and other fluorinated rubber materials. Over the years, we’ve gained solid expertise in developing high-quality fluoroelastomer base polymers and compounds, which puts us in a good position to contribute to cool innovations like this sealing solution. In this blog, I’ll be diving into the key features, benefits, and uses of the Oring De Viton Parker, giving you a better idea of how it can boost performance across various industries.

Understanding Oring De Viton Parker: Composition and Characteristics

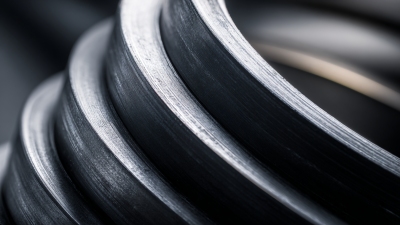

Oring De Viton Parker is pretty well-known for its amazing sealing powers across all sorts of industries. The secret? It’s mostly because of its special makeup and properties. Made from a unique fluoropolymer, Viton can handle crazy temperature swings, harsh chemicals, and ozone exposure — making it a go-to choice for tough environments. Plus, its great elastic recovery means it can seal reliably without leaks, even when pressure is all over the place.

When you're thinking about using Oring De Viton Parker, don’t forget to pay attention to temperature limits, chemical compatibility, and what your machinery specifically needs. It’s always a good idea to chat with your supplier to make sure the material you pick can handle the conditions it’ll face.

Here's a quick tip: for the best sealing results, make sure to lubricate the Oring with a compatible grease. This helps it last longer and reduces wear and tear. Also, when installing, try not to twist or stretch the Oring more than it's rated for — that kind of care keeps it working properly. Honestly, these little tricks can make a big difference, especially in tough industrial setups where reliability is everything.

Key Advantages of Oring De Viton Parker in Industrial Applications

You know, Oring De Viton Parker has really earned its reputation for top-notch sealing performance. It’s a go-to in lots of industries—think automotive, aerospace, manufacturing—you name it. One of the coolest things about these Viton seals is how well they handle extreme conditions. According to the guys at the Chemical Resistance of Materials Committee, Viton can resist temperatures from about -20°C all the way up to 200°C, and sometimes even hit a peak of 260°C! That’s way better than many of the traditional sealing options out there. Plus, all that durability means your machinery lasts longer, which helps cut down on downtime and maintenance costs—huge wins especially in high-pressure setups.

And it’s not just about heat. Viton seals are pretty much resistant to all sorts of fluids—oils, fuels, solvents—you name it. A study published in the Journal of Industrial Sealing even found that equipment with Viton seals stayed in action over 30% longer compared to those running on regular rubber seals under similar conditions. That kind of efficiency boost adds up, helping manufacturers get more done without constantly fussing over replacements. In the long run, it’s a smart, cost-effective choice.

A couple of tips: When you're picking seals for your machinery, think about the operating temperature and what fluids they’ll be exposed to. Always check the product data sheets to make sure the seals match your needs. And don’t forget—regular inspections are your friends. Keeping an eye on the seals can really extend their service life and save you headaches down the road.

How Oring De Viton Parker Improves Sealing Performance

The Oring De Viton Parker has really changed the game when it comes to sealing performance, especially in tough environments. Made from a top-tier fluorocarbon elastomer called Viton, these seals are pretty much built to handle extreme temperatures and harsh chemicals.

I read somewhere that, according to the American Society for Quality, Viton seals can handle temperatures from about -20°F all the way up to 400°F. That’s a huge plus because it means they’re useful in industries like chemicals, automotive, and aerospace—places where conditions can get really intense.

Plus, their chemical resistance is seriously impressive. If you’re dealing with acids, oils, or solvents, Viton-based seals are pretty much the go-to option. The Society of Automotive Engineers even mentioned that using Viton can cut seal failures by up to half in environments with aggressive media. That’s no small feat—it means less downtime, fewer repairs, and overall lower maintenance costs.

For companies looking to keep things running smoothly and reliably, investing in Oring De Viton Parker makes a lot of sense. It’s all about durability and dependable performance, especially when it really matters.

Comparative Analysis: Oring De Viton Parker vs. Traditional Sealing Solutions

When you compare Oring De Viton Parker to traditional sealing options, a few things really stand out—especially when it comes to the materials and how well they perform in tough environments. You see, Oring De Viton is known for being super resistant to chemicals and handling high temperatures without breaking a sweat. That kind of toughness means it keeps its shape and functionality, even under harsh conditions, making it a go-to choice in everything from cars to airplanes. On the flip side, regular seals often wear out or degrade pretty quickly when exposed to extreme heat or nasty chemicals. That usually translates into more frequent repairs and replacements, which nobody really looks forward to, right?

When you compare Oring De Viton Parker to traditional sealing options, a few things really stand out—especially when it comes to the materials and how well they perform in tough environments. You see, Oring De Viton is known for being super resistant to chemicals and handling high temperatures without breaking a sweat. That kind of toughness means it keeps its shape and functionality, even under harsh conditions, making it a go-to choice in everything from cars to airplanes. On the flip side, regular seals often wear out or degrade pretty quickly when exposed to extreme heat or nasty chemicals. That usually translates into more frequent repairs and replacements, which nobody really looks forward to, right?

Another point worth mentioning is how flexible and customizable Oring De Viton Parker is. Unlike standard seals that might only fit specific setups, this material can actually be tailored to fit all kinds of complex shapes and precise specs. That means engineers can really fine-tune the seal to perform better, cut down on friction, and get a snug fit that boosts the whole system’s efficiency. As industries push for better durability and higher performance, it’s pretty clear that Oring De Viton Parker is a step ahead of traditional solutions — making it an exciting upgrade in sealing tech.

Industry-Specific Applications of Oring De Viton Parker

Viton O-rings have really gained recognition lately for their incredible sealing performance across tons of different industries. What makes them stand out is their unique properties, which is why they’re often the go-to choice—from oil and gas setups to aerospace tech. Specifically, their chemical resistance and ability to handle high temperatures mean they can tough out pretty harsh environments. That’s a huge deal for industries where reliability under extreme conditions isn’t just nice to have, but absolutely essential. I read a report from late 2022 that said the global market for seals, including Viton O-rings, is expected to grow at a compound annual rate of over 5% over the next five years. Basically, demand is on the rise because these seals are so useful in a bunch of different industrial applications.

If you look at specific industries, Viton O-rings really show how versatile they are. In oil and gas, they’re used in wellhead sealing and fluid transfer setups — critical points where failure can cause major downtime and safety issues. Meanwhile, in the aerospace world, they help keep hydraulic systems leak-proof, which is obviously super important for safety and smooth performance. A recent report on aerospace materials even found that switching to advanced sealing options like Viton O-rings has helped boost operational efficiency. In some cases, companies saw maintenance costs drop by up to 20%. As industries keep evolving, it’s pretty clear that high-performance sealing solutions like these are only going to matter more and more.

Sealing Performance of Oring De Viton Parker Across Industries

This chart illustrates the sealing performance of Oring De Viton Parker across various industries, highlighting its effectiveness in different applications.

Maintenance Tips for Maximizing the Lifespan of Oring De Viton Parker

If you want your Oring De Viton Parker to last as long as possible, regular maintenance and sticking to good practices are really key. This type of O-ring, known for its top-notch sealing ability, is a real go-to across many industries—not surprising, considering how tough it is against extreme temperatures and harsh chemicals. To keep things running smoothly, make sure to check your O-rings often for any signs of wear, cracks, or deformities. And don’t forget—keeping the environment around them clean and free from contaminants like dust or incompatible lubricants can really help extend their lifespan.

On top of that, properly installing your O-rings is super important. Picking the right size and making sure they fit well helps prevent leaks and reduces unnecessary stress on the material. Also, try to avoid stretching or applying too much pressure on them during operation—that can cause problems down the line. Here at Sichuan Fudi New Energy Co., Ltd., we take pride in using high-quality fluoroelastomers in our products, which boost both their durability and reliability in all kinds of applications. If you follow these simple tips, you’ll keep your Oring De Viton Parker seals performing their best and lasting longer than you might expect.

Enhancing Industrial Applications with Peroxide Curable FKM Raw Polymer: Benefits and Innovations

In the realm of industrial applications, the choice of raw materials can significantly impact the performance and durability of end products. One promising material gaining attention is peroxide curable FKM (fluoroelastomer) raw polymer. Unlike conventional bisphenol curable copolymers, peroxide FKM exhibits exceptional physical properties, including superior tear resistance, enhanced chemical resistance, and improved mechanical performance. These attributes make it ideal for demanding applications where reliability and longevity are paramount.

Peroxide curable FKM is particularly effective in environments that expose materials to aggressive chemicals and extreme temperature fluctuations. Its enhanced chemical resistance allows it to maintain integrity and functionality longer than its bisphenol counterparts. Additionally, the strong mechanical properties ensure that products made with peroxide FKM can withstand significant stress and wear, making them suitable for a wide array of industrial applications, from seals in automotive engines to components in chemical processing facilities.

The innovations surrounding peroxide curable FKM are not just about superior performance; they also present opportunities for manufacturing efficiencies and cost savings. By adopting this advanced material, industries can reduce downtime caused by failures, lower replacement costs, and ultimately enhance overall productivity. This is a significant advantage in the highly competitive landscape of industrial manufacturing, where every improvement in material performance translates to greater operational efficiency.

FAQS

: Oring De Viton Parker is a sealing solution made from a high-performance fluorocarbon elastomer called Viton. Its main benefits include excellent resistance to extreme temperatures and aggressive chemicals, making it suitable for harsh industrial environments.

Seals made from Viton can withstand temperatures ranging from -20°F to 400°F, which greatly enhances their usability in various demanding industries.

Oring De Viton Parker offers unmatched chemical resistance, making it the preferred choice for applications involving acids, oils, and solvents. This quality significantly reduces failure rates.

According to the Society of Automotive Engineers, using Viton-based products can decrease the failure rates of seals exposed to aggressive media by up to 50%, ensuring greater operational efficiency and lower maintenance costs.

Regular inspections for wear, cracks, and deformation, keeping the sealing environment clean, and using proper installation techniques are key practices to extend the lifespan of Oring De Viton Parker.

Proper installation techniques are crucial to maintain the integrity of Oring De Viton Parker. Ensuring the correct size and fit can prevent leaks and minimize stress on the material.

It is important to avoid excessive stretching or pressure on the oring to maintain its integrity and performance.

High-quality fluoroelastomers should be used, as they contribute to the longevity and reliability of Oring De Viton Parker seals in various applications.

Industries such as chemicals, automotive, and aerospace can greatly benefit from using Oring De Viton Parker due to its ability to perform under harsh conditions.

Contamination from dust and incompatible lubricants can significantly reduce the lifespan and effectiveness of Oring De Viton Parker, making it crucial to keep the sealing environment clean.

Conclusion

So, let’s talk about Oring De Viton Parker — it’s actually a really cool sealing solution that's known for its top-notch material, mainly made from high-performance fluoroelastomers. If you’ve checked out our blog, you’ll see we highlight how this clever little product packs a punch in different industrial settings. It’s got some serious perks: better chemical resistance, can handle high temperatures like a champ, and it’s pretty durable all around. Honestly, it just works better than your average seals, especially in tough environments where reliability is crucial.

We also dive into how this sealing stuff applies across various industries, showing how it can really boost efficiency and keep things running smoothly. And of course, we throw in some handy tips on maintaining it so it keeps performing at its best for the long haul. Since Sichuan Fudi New Energy Co., Ltd. is all about fluoroelastomer products, we're dedicated to providing high-quality sealing solutions like Oring De Viton Parker that really meet what the industry needs.

Hope this gives you a clearer picture — it’s all about better performance and reliability in one smart package!

Related Posts

-

Optimizing Performance: Innovative Solutions Using FKM Material Properties

-

Top Strategies for Boosting Efficiency with Material Fkm Viton in Industrial Applications

-

7 Best Practices for Working with Fluorocarbon Rubber in Industrial Applications

-

The Future of Viton Sponge Rubber in Innovative Industrial Applications

-

Understanding Perfluoroelastomer O Rings Benefits and Applications in Global Markets

-

How to Choose the Right Viton Material for Your Industrial Needs

Blog Tags:

Oliver

-

Phone

-

E-mail

-

Whatsapp

-

Top