7 Reasons Why FKM Is Viton the Best Choice for Your Industrial Needs

Table of Contents

- Understanding FKM and Its Versatility in Industrial Applications

- Key Properties of Viton: Why It Stands Out Among Competing Materials

- Cost-Effectiveness of FKM: Balancing Performance and Budget

- Resistance to Harsh Environments: FKM's Superiority in Extreme Conditions

- Applications of FKM in Various Industries: A Look at Real-World Use Cases

- Comparative Analysis: FKM vs. Other Rubber Compounds in Industrial Settings

- FAQS

- Conclusion

- Related Posts

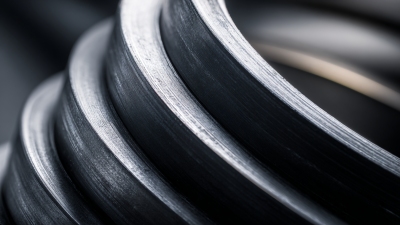

When you're dealing with industrial applications, picking the right materials really makes a difference in how well your products perform and how long they last. Out of all the options out there, FKM, also known as Viton, definitely stands out as a top-tier pick—there are lots of reasons for that. We've been around since 1998; Sichuan Fudi New Energy Co., Ltd. has over 20 years of experience in producing and selling fluoroelastomers and other fluorinated rubbers. We're really passionate about quality and innovation, especially when it comes to developing fluoroelastomer base polymers, FKM/FPM precompounds, and a variety of curing agents. That’s what makes us a leader in this space.

In this blog, I’m excited to share seven key reasons why FKM (Viton) might just be your best bet for tough industrial environments—helping you boost both efficiency and durability when things get demanding.

Understanding FKM and Its Versatility in Industrial Applications

FKM, which you might know by its trade name Viton, is pretty impressive when it comes to versatility in the industrial world. It’s highly valued because it can handle heat, chemicals, and even tough weather conditions without breaking a sweat. I read in a report from the Freedonia Group that the global market for fluoropolymer products like FKM is expected to hit around $10 billion by 2025. That’s a huge jump and really shows how much different sectors — like automotive, aerospace, and chemical processing — are relying on FKM more and more. This trend clearly shows that industries are leaning on FKM for high-performance jobs where regular elastomers just don’t cut it anymore.

Besides its ability to resist chemicals, FKM can also withstand extreme temperatures — from as low as -40°F (-40°C) up to 400°F (204°C). That kind of durability makes it a go-to material for industries that need something reliable even in the harshest conditions. The American Society for Testing and Materials (ASTM) even points out that parts made with FKM often outperform those created from regular rubber, which means less downtime and lower maintenance costs. All these features together allow manufacturers to use FKM for critical stuff like seals, gaskets, and hoses, ensuring everything runs smoothly and safely across different industrial setups.

7 Reasons Why FKM Is Viton the Best Choice for Your Industrial Needs

| Feature | Description | Application |

|---|---|---|

| Temperature Resistance | Effective in a temperature range of -20°C to +250°C. | Automotive, Aerospace |

| Chemical Resistance | Highly resistant to oils, fuels, and various solvents. | Chemical Processing |

| Durability | Excellent wear resistance, ensuring long service life. | Industrial Machinery |

| Flexibility | Maintains flexibility at low temperatures. | Food Processing |

| Abrasion Resistance | Superior resistance to wear from abrasive materials. | Construction Equipment |

| UV Stability | Resists degradation from UV exposure. | Outdoor Applications |

| Versatility | Can be formulated for various properties to meet specific needs. | Various Industries |

Key Properties of Viton: Why It Stands Out Among Competing Materials

Viton, a type of fluoroelastomer made by DuPont, has really become a go-to material in a bunch of industrial settings because of its impressive features. It’s known for handling heat, chemicals, and age better than regular rubber or silicone, which makes it stand out. For example, according to Research and Markets, Viton can handle temperatures up to around 204°C (400°F)—that’s super handy in high-temp environments like auto manufacturing or aerospace. Plus, its resistance to nasty chemicals, like fuels and solvents, is a total game-changer when you need materials that won’t break down or leak, keeping operations safe and smooth.

Another thing that makes Viton special is how well it keeps gases and fluids from passing through. A study in the Journal of Applied Polymer Science mentions that Viton’s gas permeability is up to five times lower than other elastomers—meaning it’s great for sealing stuff tight and making things last longer, like in fuel lines or hydraulic systems. And let’s not forget, Viton is pretty tough—it keeps its mechanical strength even under stress, which is a must in demanding situations. All these qualities make Viton pretty much the top choice for industries that want reliable, high-performing materials.

Cost-Effectiveness of FKM: Balancing Performance and Budget

When you're choosing materials for industrial stuff, FKM—also known as Viton—really stands out when it comes to cost-effectiveness. Just last year, a market study by MarketsandMarkets showed that the fluoropolymer market, which includes FKM, is expected to hit around 8.6 billion dollars by 2025. That growth is mainly because of how well FKM performs in tough environments. It’s pretty impressive—it's super resistant to heat, chemicals, and aging, so you don’t have to replace it as often. That actually helps save some serious cash over the long haul.

And honestly, even though FKM parts might cost a bit more upfront, their durability more than makes up for it. A report from Grand View Research mentions that FKM seals and gaskets can last up to ten times longer than traditional elastomers. Fewer replacements mean less hassle and fewer ongoing costs, which is a big win for industries that need things to run smoothly over the long term. So yeah, FKM often ends up being the smartest choice financially—despite the higher initial investment—since it pays off through better performance and less downtime in demanding industrial settings.

Cost-Effectiveness of FKM (Viton) in Industrial Applications

This bar chart illustrates the cost-effectiveness of FKM (Viton) based on key performance attributes relevant to industrial applications. Each attribute is rated on a scale from 1 to 10, showing that FKM excels in chemical resistance and overall performance while also accounting for maintenance and installation costs.

Resistance to Harsh Environments: FKM's Superiority in Extreme Conditions

When you're looking at materials for tough industrial jobs—especially those extreme conditions—FKM, better known as Viton, really stands out due to its incredible resistance to harsh environments. It’s impressive how well it holds up in high temperatures, all the while standing strong against chemicals and oils. That's a big deal for industries like automotive, aerospace, or oil & gas, where the equipment often faces nasty substances and wild temperature swings.

And honestly, FKM is a champ when it comes to outdoor use too. Many elastomers just can't handle sunlight or weathering, but Viton stays tough and intact, making it reliable and long-lasting. This means less time and money spent on maintenance and replacements, and it helps your equipment keep running smoothly even in the most demanding conditions. For manufacturers, choosing FKM often translates into better productivity and lower operational costs—that’s a win all around.

Applications of FKM in Various Industries: A Look at Real-World Use Cases

FKM, which you might know better by its brand name Viton, is pretty well-known for its amazing performance across a bunch of different industries. For example, in the automotive world, FKM seals and gaskets aren’t just your average components — they’re tough, handling really high temperatures and resisting chemicals like a champ. That makes them perfect for high-performance engines and fuel systems because they can handle aggressive fuels and oils without giving up, so they keep running smoothly and last longer. Then there’s the aerospace side of things: FKM’s durability really shines there too, where conditions can be extreme — think high altitudes and crazy temperature swings — and most regular materials just wouldn’t cut it.

But FKM’s not just for cars or planes. It also plays a major role in pharma and food processing, mainly because it can stand up to harsh cleaning agents and sterilization processes. That’s super important when you’re talking about maintaining sterile environments or meeting health regulations. Like, you’ll find FKM gaskets in pharmaceutical manufacturing equipment — because safety and cleanliness are a big deal. Plus, the oil and gas industry depends a lot on FKM seals too, since they need to keep equipment safe from corrosive stuff and high pressures. Basically, this material is pretty versatile across all sorts of sectors. When businesses decide to go with FKM, or Viton, they’re really investing in better performance, less downtime, and overall smoother operations across the board.

Comparative Analysis: FKM vs. Other Rubber Compounds in Industrial Settings

When you compare FKM (that’s fluoroelastomer, by the way) to other rubber materials, especially in industrial settings, a few things really stand out — things that make FKM kind of the superstar. It’s incredibly resistant to high temperatures, chemicals, and aging, which is a huge plus if you’re working in tough environments that demand durable materials. For example, many other rubbers tend to break down pretty quickly when faced with heat or harsh chemicals, but FKM keeps going strong and maintains its performance. You see this mostly in industries like automotive and aerospace, where reliability isn’t just a bonus—it's a must-have.

On top of that, newer studies are really shining a light on the environmental side of things. Take recycled tire rubber, for instance. It can release substances like 6PPD and its derivative, 6PPD-Q, which, honestly, are pretty toxic to both aquatic life and land animals, even at super low amounts. FKM, on the other hand, is inert—meaning it doesn’t release harmful chemicals, making it much safer for the environment. Plus, with stricter environmental rules coming into play all the time, FKM helps companies stay in line without too much hassle. All these factors add up to FKM being not just a better performer, but also a smarter, more responsible choice for today’s eco-conscious world.

FAQS

: FKM, commonly known as Viton, is a fluoroelastomer recognized for its outstanding resistance to harsh environments. It maintains performance in high temperatures and resists degradation from chemicals and oils, making it crucial for industries like automotive, aerospace, and oil & gas.

FKM has exceptional resistance to ozone and weathering, making it ideal for outdoor applications. Unlike many elastomers that degrade under sunlight, FKM retains its integrity, ensuring longevity and reliable operation in challenging weather conditions.

FKM offers superior resistance to heat, chemicals, and aging compared to other rubber compounds. It maintains integrity and performance under extreme conditions, making it especially suitable for demanding environments in the automotive and aerospace sectors.

Yes, certain rubber compounds, especially from recycled tire rubber, can release harmful contaminants like 6PPD and its derivative, 6PPD-Q, which are toxic to ecosystems. In contrast, FKM's inert properties reduce environmental risks.

By providing exceptional durability and resistance to harsh conditions, FKM reduces the frequency of maintenance and replacements. This leads to enhanced productivity and lower operational costs for industrial manufacturers.

FKM not only performs well under extreme conditions but also adheres to stringent environmental regulations due to its inert properties. This makes it a safer and more responsible choice compared to many traditional rubber compounds in today’s eco-conscious market.

Conclusion

When it comes to finding high-performance materials for industrial use, FKM — especially the well-known Viton — really stands out. This flexible fluoroelastomer is praised for its incredible resistance to tough chemicals and extreme temperatures, which makes it perfect for some of the most demanding environments out there. What’s pretty cool is that Viton isn’t just durable; it’s also cost-effective, so companies can get top-tier performance without breaking the bank.

Plus, Viton’s flexibility shines through in a bunch of industries, from automotive to aerospace, proving it’s genuinely versatile. When you stack it up against other rubber options, FKM keeps showing why it’s often the go-to choice. That’s probably why companies like Sichuan Fudi New Energy Co., Ltd. really rely on it — because it’s resilient, functional, and just makes sense for high-stakes applications. All in all, FKM, and Viton in particular, really hit the sweet spot for industrial needs.

Related Posts

-

The Future of Viton Sponge Rubber in Innovative Industrial Applications

-

Understanding Perfluoroelastomer O Rings Benefits and Applications in Global Markets

-

What is Oring De Viton Parker and How It Enhances Sealing Performance in Various Industries

-

Optimizing Performance: Innovative Solutions Using FKM Material Properties

-

7 Best Practices for Working with Fluorocarbon Rubber in Industrial Applications

-

The Ultimate Guide to Selecting Fluoroelastomer Sheets: Key Features and Industry Insights

Blog Tags:

Charlotte

-

Phone

-

E-mail

-

Whatsapp

-

Top