The Ultimate Guide to Selecting Fluoroelastomer Sheets: Key Features and Industry Insights

Table of Contents

- Understanding Fluoroelastomer Sheets: Properties and Advantages

- Essential Features to Consider When Choosing Fluoroelastomer Sheets

- Applications of Fluoroelastomer Sheets Across Various Industries

- Comparing Fluoroelastomer Sheets with Other Elastomer Materials

- Tips for Sourcing High-Quality Fluoroelastomer Sheets

- Common Mistakes to Avoid When Selecting Fluoroelastomer Sheets

- FAQS

- Conclusion

- Related Posts

Hey there! So, in today’s industrial world, Fluoroelastomer Sheets are

really making a splash because of their amazing resistance to chemicals,

ability to handle high temperatures, and solid mechanical features.

If you’ve looked into market reports lately—like that recent one from Grand View Research—you’ll see that

the global fluoroelastomer market is expected to hit around $5.28 billion by 2025.

And here’s the interesting part: it’s growing at about 5.1% each year.

The main drivers? Industries like automotive, aerospace,

and oil & gas are demanding these materials more and more.

Oh, and by the way, Sichuan Fudi New Energy Co., Ltd., has been a pretty big name in this space since 1998.

They've been producing and selling all sorts of fluoroelastomer products—think FKM/FPM precompounds

and fluorosilicone rubber—for over twenty years.

In this ultimate guide, we’re gonna walk you through what to look for when choosing Fluoroelastomer Sheets.

We’ll share industry insights and expert tips so you can make the best choice for your specific needs.

Let’s get started!

Hey there! So, in today’s industrial world, Fluoroelastomer Sheets are

really making a splash because of their amazing resistance to chemicals,

ability to handle high temperatures, and solid mechanical features.

If you’ve looked into market reports lately—like that recent one from Grand View Research—you’ll see that

the global fluoroelastomer market is expected to hit around $5.28 billion by 2025.

And here’s the interesting part: it’s growing at about 5.1% each year.

The main drivers? Industries like automotive, aerospace,

and oil & gas are demanding these materials more and more.

Oh, and by the way, Sichuan Fudi New Energy Co., Ltd., has been a pretty big name in this space since 1998.

They've been producing and selling all sorts of fluoroelastomer products—think FKM/FPM precompounds

and fluorosilicone rubber—for over twenty years.

In this ultimate guide, we’re gonna walk you through what to look for when choosing Fluoroelastomer Sheets.

We’ll share industry insights and expert tips so you can make the best choice for your specific needs.

Let’s get started!

Understanding Fluoroelastomer Sheets: Properties and Advantages

Fluoroelastomer sheets are really catching people's attention these days, especially because they’re so good at resisting harsh chemicals and handling high temperatures. They’ve got some pretty cool features—like being hydrophobic and even having self-cleaning abilities—which makes them perfect for really tough, durable applications. Recent research has shown that when these materials are processed using advanced template methods at higher temperatures, their hydrophobic qualities get even better, boosting their self-cleaning performance. It just goes to show how versatile and useful these materials can be across different environments.

Fluoroelastomer sheets are really catching people's attention these days, especially because they’re so good at resisting harsh chemicals and handling high temperatures. They’ve got some pretty cool features—like being hydrophobic and even having self-cleaning abilities—which makes them perfect for really tough, durable applications. Recent research has shown that when these materials are processed using advanced template methods at higher temperatures, their hydrophobic qualities get even better, boosting their self-cleaning performance. It just goes to show how versatile and useful these materials can be across different environments.

If you’re thinking about using fluoroelastomer sheets, a little tip—make sure you really understand what your application requires. First off, check the chemical compatibility—using the wrong type could lead to the material breaking down. Also, newer blends like polyamide 6 combined with fluoroelastomer for thermoplastic elastomers bring better mechanical strength and can handle higher temperatures, which might be just what you need for demanding jobs. My advice? Take a look into how these blends are structured—like their morphology—as this can really influence their overall performance.

And here’s something pretty interesting: there are newer composites that include tube-like halloysite clay, which show some impressive dynamic mechanical properties. If you're after something that's both flexible and strong, definitely consider these natural clay mineral-based composites. Not only can they boost performance, but they’re also more eco-friendly, which is always a nice bonus.

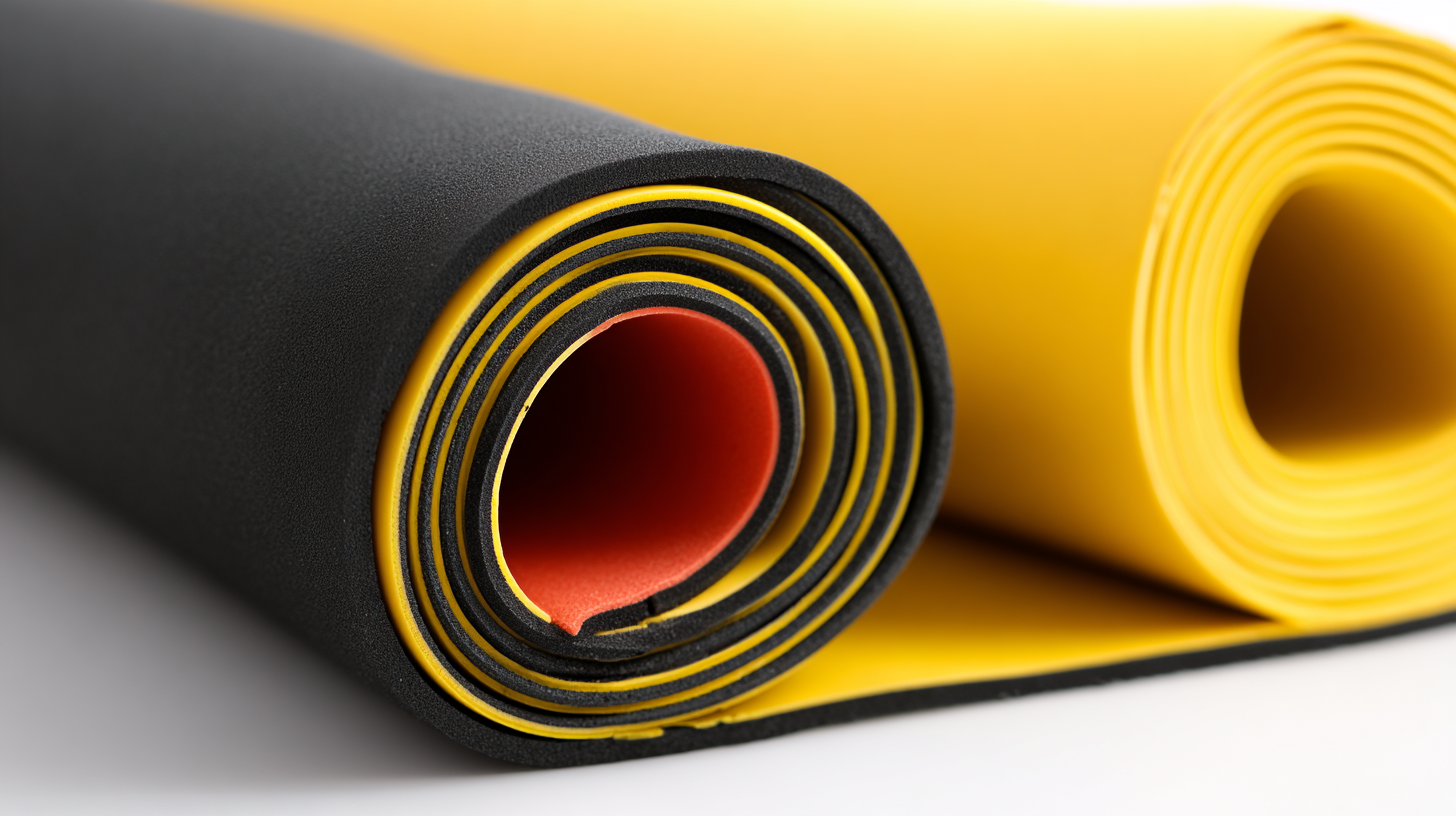

Essential Features to Consider When Choosing Fluoroelastomer Sheets

When you're choosing fluoroelastomer sheets, there are a few key things you really want to keep in mind to make sure they’re a good fit for what you need. First off, chemical resistance is a biggie—these materials are known for holding up pretty well against tough chemicals, so they’re perfect for industries like oil and gas, pharma, or automotive work. Don’t forget to check how they handle temperature either—some applications might call for sheets that can handle super hot or cold conditions without breaking a sweat.

Then, it’s also important to look at their mechanical properties, like tensile strength and how well they resist compression set. You want something durable that’ll last, but also something that keeps its sealing skills under pressure when things are moving around. The thickness of the sheets is another thing to consider—getting the right thickness can really make a difference in how they perform for your specific project. If you pay attention to these details, you’ll be in a much better spot to choose the right material and keep your products reliable and efficient.

Applications of Fluoroelastomer Sheets Across Various Industries

You know, fluoroelastomer sheets have really made a name for themselves across a bunch of industries thanks to their incredible resistance to chemicals, ability to handle high temperatures, and flexibility. You’ll mostly find them working their magic in sectors like automotive, aerospace, and pharma—places where the standards are super high and reliability is key. For example, in the automotive world, more and more manufacturers are turning to fluoroelastomers for sealing and gasket stuff. Actually, a 2022 report mentioned that the demand’s expected to grow by over 5% annually in the next few years—that’s pretty significant. The aerospace industry isn’t far behind either; they use these sheets for components that need to survive in extreme conditions, which really helps with safety and overall performance.

When you're picking out fluoroelastomer sheets for your project, it’s smart to think about a few things—like how strong it is (tensile strength), how well it resists compression (compressive set), and the temperature limits. A quick tip: it’s always a good idea to chat with a materials engineer to make sure you’re choosing the right grade for both your current needs and what might come up down the line. Oh, and industries like food processing and pharma have even stricter rules. So, make sure to look for sheets that are certified for safety and performance—that can really help with compliance and keeping your product top quality.

And hey, the versatility of fluoroelastomers doesn’t stop there. They’re also widely used in oil and gas, thanks to their outstanding resistance to harsh chemicals and extreme temperatures. This means less downtime and lower maintenance costs overall. My tip? Take a close look at your specific application to pick the right fluoroelastomer sheet—it’ll help you get the best efficiency and last longer in the field.

The Ultimate Guide to Selecting Fluoroelastomer Sheets: Key Features and Industry Insights

| Feature | Description | Applications | Industry |

|---|---|---|---|

| Temperature Resistance | Stable performance from -20°C to 250°C | Seals, gaskets | Automotive, aerospace |

| Chemical Resistance | Highly resistant to oils, fuels, and solvents | Piping, linings | Chemical processing, oil & gas |

| Flexibility | Maintains flexibility at low temperatures | Hoses, diaphragms | Pharmaceuticals, food processing |

| Durability | Excellent wear and tear resistance | O-rings, seals | Manufacturing, automotive |

| Low Compression Set | Retains shape under prolonged compression | Gaskets, seals | Aerospace, automotive |

Comparing Fluoroelastomer Sheets with Other Elastomer Materials

You know, fluoroelastomer sheets have really been making waves across different industries lately. They’re praised for their incredible resistance to high temps, harsh chemicals, and oils — pretty impressive, right? When you stack them up against other kinds of elastomers, it’s clear that sheets made by companies like Sichuan Fudi New Energy Co., Ltd. tend to outperform in tough environments. Unlike your average rubber, these materials hold up and stay flexible even in extreme conditions, which is why they’re so popular in aerospace, automotive, and chemical industries.

Plus, one of the coolest things about fluoroelastomer sheets is their low permeation rate — that’s basically how well they keep things sealed and durable over time. That’s a big deal because, compared to silicone or natural rubber, they don’t break down or lose effectiveness when dealing with aggressive chemicals or crazy thermal cycles. Sichuan Fudi New Energy Co., Ltd. has been in the game for over two decades, honing their craft in making fluoroelastomer products that can really stand up to modern industry needs. They’ve got the experience and expertise to deliver materials that not only meet all the tough standards but also perform reliably in critical situations — no surprises there.

The Ultimate Guide to Selecting Fluoroelastomer Sheets: Key Features and Industry Insights

Tips for Sourcing High-Quality Fluoroelastomer Sheets

When you're on the hunt for high-quality fluoroelastomer sheets, it's really important to pay attention to their chemical makeup and how they perform—making sure they fit your specific needs. So, here’s some good news: recent advancements have really pushed the envelope, especially with peroxide-curable fluoroelastomers that are made without fluorosurfactants. That’s a big deal because it can mean better environmental compliance and safer products overall. With all the buzz about chemicals that might pose risks, it’s smart to pick materials that not only deliver on performance but also tick those strict health and safety boxes.

When you're choosing your sheets, I’d suggest leaning towards suppliers who are transparent about how their products are made and who can provide those certifications. It helps to see products that have been thoroughly tested for durability and chemical resistance—things you definitely want in the mix. Also, don’t forget to consider manufacturers that follow eco-friendly and sustainable practices; it’s a good sign of overall quality and safety.

And, if possible, look for vendors who offer customization options. Being able to tweak specifications to suit your specific application can really make a difference in how well the material performs. By keeping these tips in mind, you’ll be able to make smarter, more confident choices—ensuring you end up with the best material for your project, without the headache.

Common Mistakes to Avoid When Selecting Fluoroelastomer Sheets

When you're choosing fluoroelastomer sheets, it’s pretty easy to overlook some key factors—things that could end up costing you more than you'd like. One common mistake? Not really taking the time to understand what your specific application needs. Different setups call for different features — like how well the material resists heat, chemicals, or how strong it needs to be. If you don’t get a clear picture of what your project demands, you might end up picking a sheet that just doesn’t cut it, which could lead to failures or inefficiencies down the line.

Another mistake I see a lot is ignoring manufacturer specs and certifications. Not all fluoroelastomer sheets are built the same—quality and compliance can vary a lot. It’s super important to double-check that the sheets you pick meet industry standards and have the right certifications. Doing your homework here gives you peace of mind and makes sure you’re getting a product capable of handling the conditions you’re working with. By paying attention to these little details, you’ll be able to avoid costly missteps and make smarter, more confident decisions for your project’s success.

FAQS

: Key features to consider include chemical resistance, temperature resistance, mechanical properties (such as tensile strength and compression set), and the appropriate thickness based on application requirements.

They are preferred due to their exceptional chemical resistance, temperature stability, and flexibility, allowing them to perform reliably under harsh conditions.

The demand for fluoroelastomer sheets in the automotive industry is projected to grow at a CAGR of over 5% in the next five years.

Fluoroelastomer sheets offer superior performance in harsh environments, maintaining integrity and flexibility at high temperatures and in aggressive chemicals, unlike standard rubber, silicone, or natural rubber.

Industries should look for fluoroelastomer sheets that are certified for safety and performance to meet stringent regulatory standards.

The thickness of fluoroelastomer sheets can significantly affect their performance, so it is essential to select an appropriate thickness based on the specific demands of the project.

Consulting with a materials engineer ensures that the selected grade of fluoroelastomer meets both current and future operational demands, optimizing product reliability and efficiency.

In the oil and gas industry, fluoroelastomer sheets reduce downtime and maintenance costs due to their superior resistance to harsh chemicals and temperature extremes.

Low permeation rates enhance the durability and reliability of fluoroelastomer sheets, making them suitable for applications that face aggressive chemicals and high thermal cycles.

Sichuan Fudi New Energy Co., Ltd. has over 20 years of experience in the production and marketing of fluoroelastomer products.

Conclusion

Hey, if you're into stuff like materials and engineering, you’ll definitely want to check out "The Ultimate Guide to Selecting Fluoroelastomer Sheets." It’s packed with all the essential info you need to understand why these sheets are such a big deal across various industries. The guide walks you through key features to watch out for—like how well they handle extreme temperatures, chemicals, or even rough weather. Plus, you'll get a good look at the different ways these sheets are used in sectors like automotive, aerospace, and oil and gas — talk about versatile!

They also do a nice side-by-side comparison of fluoroelastomer sheets with other elastomers, which is super helpful if you’re trying to figure out the best fit for your project. And if you're concerned about quality and sourcing, no worries — the guide includes tips to help you find reliable products and steer clear of common pitfalls. Honestly, it’s a pretty handy resource whether you’re a seasoned pro or just dipping your toes into the material selection game.

Of course, with over 20 years of experience in making and selling fluoroelastomer materials, Sichuan Fudi New Energy Co., Ltd. knows a thing or two about what works best. So, if you’re thinking of using these materials, this guide might just have the insights you need to make smarter choices and get the most out of our top-notch products.

Related Posts

-

Optimizing Performance: Innovative Solutions Using FKM Material Properties

-

7 Reasons Why FKM Is Viton the Best Choice for Your Industrial Needs

-

How to Choose the Right Viton Material for Your Industrial Needs

-

Top Strategies for Boosting Efficiency with Material Fkm Viton in Industrial Applications

-

Ultimate Guide to Understanding the Benefits of Fkm Rubber in Industrial Applications

-

Understanding Perfluoroelastomer O Rings Benefits and Applications in Global Markets

Blog Tags:

Oliver

-

Phone

-

E-mail

-

Whatsapp

-

Top