Ultimate Guide to Understanding the Benefits of Fkm Rubber in Industrial Applications

Table of Contents

- The Unique Chemical Properties of FKM Rubber in Industry Applications

- 5 Key Advantages of Using FKM Rubber Over Other Elastomers

- How FKM Rubber Enhances Performance in Extreme Conditions

- 4 Critical Industries Benefiting from FKM Rubber Solutions

- Practical Tips for Selecting and Using FKM Rubber in Manufacturing

- Understanding FKM Rubber: Maintenance and Longevity Tips for Industrial Use

- FAQS

- Conclusion

- Related Posts

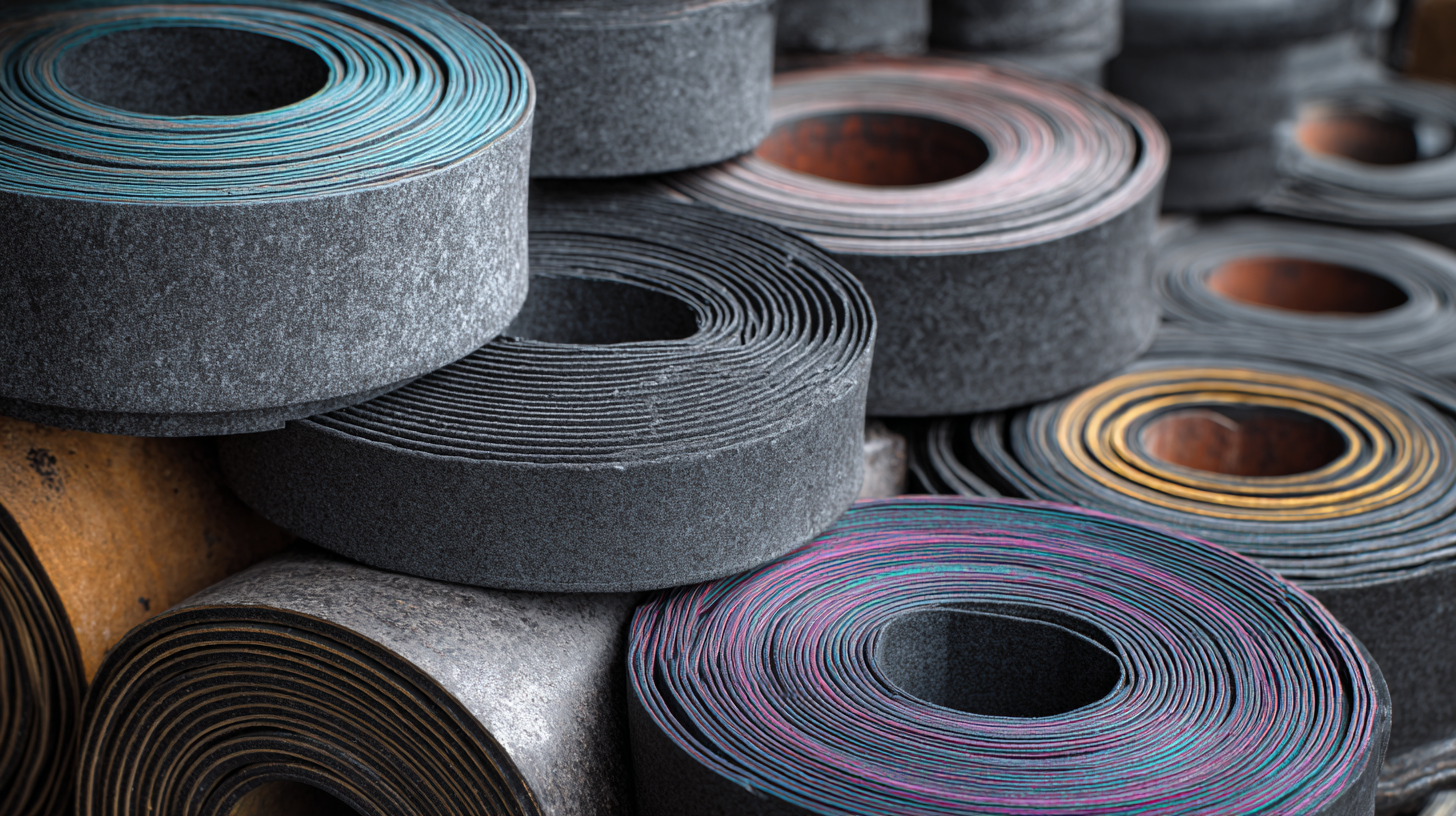

In the fast-changing world of industrial applications, the materials we choose really make a difference when it comes to efficiency, durability, and reliability. And among these, FKM rubber definitely stands out as a top pick—especially for industries that need something tough against heat, chemicals, and mechanical stress. Sichuan Fudi New Energy Co., Ltd., has been around since 1998, and they’ve spent over 20 years perfecting and marketing fluoroelastomers and all kinds of fluorinated rubber materials, including some pretty high-quality FKM rubber products. The goal of this guide is to break down all the great benefits of FKM rubber—what makes it special, its unique properties, and the many ways it's used across different industries. By getting a better understanding of how FKM rubber can boost performance and help your products last longer, businesses can make smarter choices that lead to innovation and success in their fields.

The Unique Chemical Properties of FKM Rubber in Industry Applications

FKM rubber is pretty amazing when it comes to resisting chemicals and handling heat — it’s become a go-to material for a bunch of industrial uses. It can go from as low as -20°C all the way up to +250°C, and it’s tough enough to handle harsh stuff like fuels, oils, and solvents without breaking a sweat. According to Dow Chemical, FKM’s ability to resist breaking down makes it really popular for seals and gaskets, especially in the automotive and aerospace worlds where you just can’t afford any failures.

What’s really cool about FKM is all that fluorine in its structure, which boosts its resistance to oxidation and ozone damage. That’s why it’s a solid choice for outdoor applications, where exposure to the elements can ruin other rubber types. Interestingly, a report from Grand View Research mentioned that the global market for FKM is expected to grow at about 5.1% annually from 2021 to 2028. This just highlights how much industries like oil and gas, pharmaceuticals, and food processing are relying on FKM for its durability and safety. As companies keep pushing for longer-lasting and more reliable products, FKM rubber’s special chemical properties are making it even more popular for tricky industrial jobs.

5 Key Advantages of Using FKM Rubber Over Other Elastomers

You know, FKM rubber—also called fluorocarbon rubber—has been gaining popularity in all sorts of industrial settings lately. Why? Well, it’s mainly because of its impressive qualities. For starters, one of the biggest perks is its incredible resistance to chemicals. Unlike a lot of other elastomers, FKM can handle exposure to nasty chemicals, oils, and solvents without breaking a sweat. That’s why industries like automotive and aerospace love it—they often deal with pretty tough conditions where only the tough stuff will do.

How FKM Rubber Enhances Performance in Extreme Conditions

You know, FKM rubber, also called fluorocarbon rubber, is pretty impressive when it comes to handling tough conditions. It’s often the go-to choice in all sorts of industrial settings because of its ability to perform under extreme circumstances. One of the biggest perks? Its incredible resistance to heat and chemicals. According to a report from the Rubber Manufacturers Association, FKM can handle temperatures from about -20°C all the way up to 250°C. That’s pretty amazing, especially for industries like automotive and aerospace where the materials need to keep working, no matter how hot or harsh things get.

And let’s not forget about its resistance to nasty chemicals—think oils, solvents, acids, and fuels. A study published in the Journal of Applied Polymer Science actually mentions that FKM keeps its mechanical properties pretty much intact even after long-term exposure to these substances. That’s a game changer for sectors like oil and gas, where equipment is constantly getting exposed to corrosive stuff. It means longer-lasting parts and fewer maintenance headaches.

Whether it’s used in seals, gaskets, or hoses, adding FKM rubber really bumps up the reliability and efficiency of machinery working under tough conditions. It’s no wonder it’s such a popular choice in heavy-duty applications.

4 Critical Industries Benefiting from FKM Rubber Solutions

When it comes to industrial applications, FKM rubber really stands out thanks to its incredible durability and ability to resist extreme conditions. It's honestly such a versatile material, especially in four key industries: automotive, aerospace, oil and gas, and pharmaceuticals. Each of these fields demands tough, reliable materials that can handle high temperatures and harsh chemicals — which is exactly what makes FKM rubber such a great pick.

In the automotive world, you'll find FKM rubber everywhere — from fuel systems to gaskets and seals. It keeps things running smoothly even under a lot of pressure, thanks to its resistance to all kinds of fuels, lubricants, and temperature swings. This means cars not only perform better but are also safer. Moving to aerospace, FKM’s strength lies in its ability to cope with super tough environments — it’s a key material in engine parts and fuel systems, where integrity can’t be compromised.

The oil and gas industry relies heavily on FKM rubber too. Its resilience against nasty chemicals and the extreme conditions during extraction and refining makes it a go-to solution. And let’s not forget the pharma side of things — they depend on FKM for seals and gaskets that keep medical equipment sterile and safe. All in all, these industries show just how crucial FKM rubber is in ensuring everything runs smoothly and efficiently.

Ultimate Guide to Understanding the Benefits of FKM Rubber in Industrial Applications

This chart illustrates the benefits of FKM rubber across four critical industries. Automotive applications show a significant reliance on FKM for its durability, while aerospace, chemical processing, and pharmaceutical industries also leverage its exceptional resistance to high temperatures and chemicals.

Practical Tips for Selecting and Using FKM Rubber in Manufacturing

When you're choosing FKM rubber for industrial use, it’s really important to keep in mind what makes it special—its ability to handle tough conditions, for one. I’ve come across a report from MarketsandMarkets, and it’s pretty interesting: they predict that the global demand for fluoropolymer materials, including FKM, will hit around $1.4 billion by 2025. A big part of that’s thanks to how well FKM resists chemicals and stays stable at high temperatures. That’s why it’s so popular in sectors like automotive, aerospace, and oil and gas — industries where durability really matters.

If you’re thinking about using FKM rubber, a good starting point is to get familiar with its different grades and formulations. Not all FKM is created equal—some versions are more resistant to harsh chemicals, especially those with a higher fluorine content, but those can also bump up the cost. So, choosing the right type really depends on what you need—like the temperature range it has to handle or the chemicals it’ll contact. Also, don’t overlook proper installation and maintenance. The Rubber Manufacturers Association points out that if you don’t handle these materials carefully, they might fail sooner than expected. Following some good practices can totally help you get the most out of FKM, keeping your operations running smoothly and efficiently.

Understanding FKM Rubber: Maintenance and Longevity Tips for Industrial Use

FKM rubber is pretty impressive when it comes to resisting heat, chemicals, and oils. Because of these qualities, it’s become a go-to material for lots of industrial stuff. If your business relies on high-quality seals, gaskets, or O-rings, you really need to get a good handle on how to take care of your FKM products. Doing regular checks and storing them properly can seriously extend their lifespan. Oh, and a quick tip—keep FKM rubber out of direct sunlight and avoid exposing it to high temperatures when you're not using it. Those factors can speed up the wear and tear.

Using FKM rubber in your manufacturing process isn't just about making your products more durable—it’s also a smart move for sustainability. Companies like Sichuan Fudi New Energy Co., Ltd. have been making and selling fluoroelastomers for over 20 years, and they really know their stuff. They focus on creating high-performance materials that stand up to tough environments. By choosing top-quality FKM, industries can better handle exposure to harmful chemicals and temperature changes, all while making their operations smoother and more efficient.

FAQS

: FKM rubber is known for its outstanding chemical resistance and thermal stability, making it a preferred material in various industrial applications.

FKM rubber can withstand temperatures ranging from -20°C to +250°C.

FKM rubber is favored in these industries due to its resistance to degradation and reliability under harsh conditions, which are crucial for seals and gaskets.

The fluorine content in FKM rubber significantly enhances its resistance to oxidation and ozone degradation.

FKM rubber performs excellently in outdoor applications due to its resistance to environmental factors, unlike other elastomers that may degrade.

The global FKM market is expected to grow at a CAGR of 5.1% from 2021 to 2028.

FKM rubber is gaining importance in the oil and gas, pharmaceuticals, and food processing industries.

FKM rubber maintains its mechanical properties even when exposed to aggressive chemicals, such as acids and fuels, showing minimal degradation over time.

The integration of FKM rubber in seals, gaskets, and hoses can significantly improve the reliability and efficiency of machinery operating under extreme conditions.

The benefits of using FKM rubber include a longer service life and reduced maintenance costs due to its exceptional resistance to corrosive substances.

Conclusion

You know, in the industrial world, FKM Rubber really stands out — mainly because of its unique chemical properties. It’s pretty much a go-to when you need something tough and durable. What’s cool about this material is that it comes with a bunch of advantages over other elastomers. Think about things like better chemical resistance,standing up to high temperatures, and staying elastic under pressure. And honestly, it performs like a champ in really extreme conditions too. That’s why you’ll find it being used a lot in industries like automotive, aerospace, oil and gas, and even pharmaceuticals.

Sichuan Fudi New Energy Co., Ltd. has been in this game for over 20 years, developing top-notch FKM rubber — from basic polymers all the way to custom compounds. If you’re a manufacturer trying to pick the right rubber, a few practical tips about choosing and using FKM can really make a difference. They can help improve how long your products last and how well they perform, especially in tough environments. With a little proper care and maintenance, FKM rubber can reliably handle the demands of industry, making it a favorite material out there for today’s manufacturing needs.

Related Posts

-

How to Choose the Right Viton Material for Your Industrial Needs

-

Optimizing Performance: Innovative Solutions Using FKM Material Properties

-

7 Best Practices for Working with Fluorocarbon Rubber in Industrial Applications

-

Understanding Perfluoroelastomer O Rings Benefits and Applications in Global Markets

-

What is Oring De Viton Parker and How It Enhances Sealing Performance in Various Industries

-

Top Strategies for Boosting Efficiency with Material Fkm Viton in Industrial Applications

Blog Tags:

Charlotte

-

Phone

-

E-mail

-

Whatsapp

-

Top