What is Viton Rubber Material and Why It is Essential in Industrial Applications

Table of Contents

- Understanding Viton Rubber: Composition and Properties

- Key Benefits of Viton Rubber in Industrial Applications

- Comparative Analysis: Viton Rubber vs. Other Rubber Materials

- Viton Rubber's Resistance to Chemicals and Extreme Temperatures

- Applications of Viton Rubber in Various Industries

- Best Practices for Using and Maintaining Viton Rubber Products

- Exploring the Benefits and Applications of Raw Gum FVMQ Base Polymer in Modern Industry

- FAQS

- Conclusion

- Related Posts

When it comes to industrial applications, you can’t really overstate how important Viton Rubber is. It’s well-known for its incredible resistance to heat, chemicals, and weathering — pretty much a lifesaver in many sectors like automotive, aerospace, and chemical processing.

Over here at Sichuan Fudi New Energy Co., Ltd., we've been working since 1998, focusing on making and selling fluoroelastomers and other fluorinated rubber materials. With more than 20 years under our belt, we’ve become pretty good at producing top-quality stuff, like fluoroelastomer base polymers and FKM compounds. That just goes to show how essential Viton really is for boosting performance and durability in industrial settings.

Over here at Sichuan Fudi New Energy Co., Ltd., we've been working since 1998, focusing on making and selling fluoroelastomers and other fluorinated rubber materials. With more than 20 years under our belt, we’ve become pretty good at producing top-quality stuff, like fluoroelastomer base polymers and FKM compounds. That just goes to show how essential Viton really is for boosting performance and durability in industrial settings.

In this article, I’ll dig into the properties of Viton Rubber, share some insights, and offer tips on how to make the most out of it in different industries — because it’s a game changer for keeping things running smoothly and reliably.

Understanding Viton Rubber: Composition and Properties

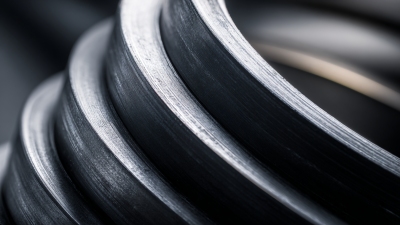

Viton rubber, which is a type of fluoroelastomer, is pretty well-known for its incredible resistance to heat, chemicals, and oils. That’s why it’s such a crucial material in a bunch of industrial settings. Basically, it’s made mostly of vinylidene fluoride and hexafluoropropylene, and its unique polymer structure really helps it perform like a champ. I remember reading a report from the Freedonia Group — they’re saying the global market for fluoroelastomers could hit over $6 billion by 2025. Most of that growth? Thanks to industries like automotive and aerospace, where you really need durable, reliable components.

When it comes to properties, Viton can handle some pretty intense heat — up to 250°C (482°F) if you’re talking continuous use, and even more for short bursts. Plus, it doesn’t really lose its shape or sealing ability over time, even in tough environments, thanks to its low compression set. Interestingly, a study in the American Journal of Materials Science shows Viton stays solid when in contact with aggressive chemicals, showing resistance levels over 90% for certain hydrocarbon oils and fuels. That’s why it’s so popular for making gaskets, seals, and O-rings — where really trusting your material to do its job is a must.

Key Benefits of Viton Rubber in Industrial Applications

Viton rubber is pretty impressive stuff—it's a high-performance fluoropolymer elastomer that’s well known for standing up really well against heat, chemicals, and tough environments. Thanks to its unique makeup, it’s a go-to material in a bunch of different industries, especially in chemical processing, auto manufacturing, and aerospace. One of the coolest things about Viton is that it can stay flexible and hold its shape even when things get super hot or cold—from about -20°C all the way up to 260°C. That’s a huge plus for parts that need to work reliably under tough conditions.

And let’s not forget, Viton’s chemical resistance is pretty amazing too—acids, solvents, fuels—you name it, it handles them all. That means seals, gaskets, and O-rings made from Viton tend to last longer and perform better, which cuts down on how often you need to replace or fix them. The market for synthetic rubber is really booming—it's expected to grow from around $32.8 billion in 2024 to over $48 billion by 2032. So yeah, the demand for tough, reliable materials like Viton is definitely on the rise, and it’s playing a big role in making industrial systems more efficient and durable.

Comparative Analysis: Viton Rubber vs. Other Rubber Materials

Viton rubber is pretty impressive when you think about its resistance to heat, chemicals, and aging—it's often a go-to in industrial settings, especially when compared to other types of rubber. I came across a report from the American Rubber Institute that mentions Viton (which is actually a type of fluoroelastomer) can handle temperatures from as low as -20°F all the way up to 400°F. That’s pretty wild, considering natural rubber, for instance, starts to lose its elasticity above around 130°F. Because of this outstanding thermal stability, industries like aerospace and automotive often rely on Viton—where stuff needs to withstand extreme conditions without breaking down.

And then there’s the chemical resistance. Viton really shines here too. According to the International Rubber Research and Development Board, it can resist a whole bunch of aggressive substances—things like fuels, acids, and solvents—sometimes up to 10 times longer than materials like neoprene or SBR. That’s a big deal, especially when you’re dealing with seals and gaskets in chemical plants, where exposure to harsh chemicals can really wear down other materials fast. Choosing Viton over the competition often means fewer replacements, less downtime, and lower maintenance costs—all huge perks in this line of work.

Viton Rubber's Resistance to Chemicals and Extreme Temperatures

Viton rubber, which is actually a kind of fluoroelastomer, is pretty well-known for being super resistant to all sorts of chemicals and extreme temperatures. It’s basically a go-to material in a bunch of heavy-duty industrial stuff. According to research from the Chemical Resistant Materials Association, Viton can handle temperatures from about -20°F all the way up beyond 400°F—and it does so without losing its shape or performance. That kind of versatility means it’s perfect for tough environments like oil and gas extraction, chemical plants, and even automotive applications.

What’s really impressive about Viton rubber is its chemical resistance. It can handle exposure to nasty stuff like acids, oils, and fuels without breaking a sweat. A report from the American Society for Testing and Materials even shows that Viton beats out conventional rubber in resisting over 90% of tested chemicals. So, not only does it last longer, reducing the need for repairs and replacements, but it also keeps costs down. It’s kind of a no-brainer for manufacturers looking for reliable, durable solutions.

**Quick tip:** When you’re picking out Viton rubber for your project, make sure to think about what chemicals it'll be exposed to, and the temperature range you’ll need. Getting these details right can save you from headaches later on. Oh, and don’t forget to look for certifications like ASTM compliance—that’s a good way to be sure you’re getting quality stuff that holds up in tough conditions.

Viton Rubber Material Resistance Comparison

This chart illustrates the resistance of Viton rubber to various chemicals and extreme temperatures compared to other common elastomers. The values represent the level of resistance (on a scale from 1 to 10) for each material.

Applications of Viton Rubber in Various Industries

Viton rubber, which is a type of fluorocarbon elastomer, is pretty well-known for its incredible properties. Because of this, it's a go-to material in a bunch of different industries. What makes it really stand out is its ability to handle crazy high or low temperatures and survive harsh chemicals. That’s why you see it everywhere — from cars and planes to oil rigs. In the automotive world, for example, Viton is commonly used in fuel system seals and gaskets. It’s reliable and tough, preventing leaks even when the car's pushing performance to the limit.

When it comes to aerospace, Viton rubber’s resistance to fuel and oil is a big deal, especially since parts often have to deal with all kinds of volatile substances. Plus, it can hold up against the extreme temperatures you find high up in the atmosphere, so it keeps its shape and strength no matter the altitude. The oil and gas industry also loves Viton for its durability and chemical resistance, making it perfect for seals and O-rings on equipment used in exploration and extraction. All in all, Viton’s versatility and dependability have really made it a must-have in these fields — helping keep everything safe and running smoothly.

What is Viton Rubber Material and Why It is Essential in Industrial Applications

| Industry | Key Applications | Benefits of Viton Rubber |

|---|---|---|

| Aerospace | Seals and O-rings for aircraft components | High temperature resistance, fuel and oil compatibility |

| Automotive | Fuel system seals, gaskets | Durability and chemical resistance |

| Chemical Processing | Hoses, seals for corrosive chemicals | Excellent resistance to aggressive chemicals |

| Pharmaceuticals | Seals in production equipment | Compliance with regulatory standards |

| Food Processing | Gaskets and seals for food equipment | Non-toxic and versatile material properties |

Best Practices for Using and Maintaining Viton Rubber Products

When it comes to getting the most out of Viton rubber products in industrial settings, following the right use and maintenance tips really makes all the difference. You see, Viton is famous for its incredible resistance to heat, chemicals, and oil, which is why it’s so popular in industries like aerospace and automotive. According to a report from Grand View Research, the global demand for fluoropolymer materials like Viton is expected to hit around $8.5 billion by 2028—that just shows how important it is to understand how to care for these materials properly.

One thing you definitely want to do is make sure your Viton products are compatible with the chemicals they'll encounter. It’s a good idea to check out the Chemical Resistance Guide from the manufacturer—skipping that step could mean ending up with early damage. Also, proper installation is key to avoiding any accidental harm. And don’t forget about regular inspections! Catching wear and tear early can really make a difference. A study in the International Journal of Industrial Chemistry mentions that sticking to routine maintenance might even boost the lifespan of Viton seals and gaskets by up to 30%. That’s a pretty big deal when you’re trying to keep everything running smoothly and safely in demanding environments.

Exploring the Benefits and Applications of Raw Gum FVMQ Base Polymer in Modern Industry

Exploring the Benefits and Applications of Raw Gum FVMQ Base Polymer in Modern Industry

The raw gum FVMQ (Fluorosilicone) base polymer represents a significant advancement in polymer technology, primarily due to its unique properties. This copolymer, which consists of methyl-3,3,3-trifluoropropylsiloxane and vinyl monomer, is well-regarded for its exceptional thermal stability and chemical resistance. With molecular weights that vary depending on specific applications, this versatile material can be tailored to meet various industry needs, making it an essential component in sectors such as aerospace, automotive, and electronics.

Moreover, the vinyl content in the raw gum FVMQ base polymer allows for enhanced compatibility with other materials, promoting efficient bonding and curing processes. This feature not only improves performance but also expands its application range, from sealants and adhesives to coatings that require long-lasting durability in harsh environments. For companies interested in integrating this advanced polymer into their processes, we offer tailored solutions based on the precise molecular weight and vinyl content required. Additionally, we provide free stock samples to facilitate evaluations, ensuring you can find the ideal grade for your specific application efficiently. For inquiries or orders, our team is ready to assist you.

FAQS

: Viton rubber, a type of fluoroelastomer, is primarily composed of vinylidene fluoride and hexafluoropropylene. It is known for its exceptional resistance to heat, chemicals, and oils.

Viton rubber is commonly used in the automotive, aerospace, and oil and gas industries due to its durability and reliable performance in harsh environments.

Viton rubber exhibits excellent thermal stability, capable of withstanding continuous use at temperatures up to 250°C (482°F) and even higher during intermittent applications.

Viton maintains its integrity in contact with various aggressive chemicals, demonstrating resistance levels of over 90% in certain hydrocarbon oils and fuels.

Typical applications for Viton rubber include gaskets, seals, and O-rings, particularly in areas where reliability and performance under extreme conditions are essential.

Viton rubber is preferred for automotive fuel systems because of its durability and reliability in preventing leaks under high-performance conditions.

In the aerospace industry, Viton rubber is utilized for its resistance to fuel and oil, ensuring structural integrity in high-altitude environments and exposure to volatile substances.

Viton rubber offers robust chemical resistance, making it ideal for rubber seals and O-rings used in exploration and production equipment in the oil and gas industry.

The global market for fluoroelastomers, projected to reach over $6 billion by 2025, is largely driven by demand from the automotive and aerospace industries for durable components.

Conclusion

Viton rubber, which is a type of fluoroelastomer, is pretty well-known for its incredible properties. That’s why you’ll find it playing a crucial role in all sorts of industrial settings. Basically, its unique makeup helps it stand up to harsh chemicals and extreme temperatures — making it super durable and trustworthy, even in tough environments. Some of the biggest perks of Viton rubber? It seals really well and lasts a long time — far better than many other types of rubber, especially in demanding industries like auto, aerospace, or chemical processing.

Now, speaking of expertise, Sichuan Fudi New Energy Co., Ltd. has been a major player in producing and marketing fluorinated rubber for over 20 years. They really know their stuff when it comes to not just making high-quality Viton products but also sharing the best tips for using and caring for them. That kind of know-how helps these materials perform at their best and last even longer. All in all, Viton rubber isn’t just another material — it’s a key part of modern manufacturing, ensuring everything runs smoothly, safely, and efficiently across different sectors.

Related Posts

-

What is Oring De Viton Parker and How It Enhances Sealing Performance in Various Industries

-

Optimizing Performance: Innovative Solutions Using FKM Material Properties

-

How to Source Chemours FKM for Enhanced Performance in Your Applications

-

Top Strategies for Boosting Efficiency with Material Fkm Viton in Industrial Applications

-

How to Choose the Right Viton Sheet for Your Industrial Needs

-

Ultimate Guide to Understanding the Benefits of Fkm Rubber in Industrial Applications

Blog Tags:

Charlotte

-

Phone

-

E-mail

-

Whatsapp

-

Top