Factory Free sample Oring Ffkm - Peroxide Curable FKM Raw Polymer – FUDI

Stock Sample is Free & Available

Factory Free sample Oring Ffkm - Peroxide Curable FKM Raw Polymer – FUDI Detail:

Peroxide curing FKM is terpolymer of hexafluoropropylene, vinylidene fluoride and tetrafluoroethylene. It has below properties compare with traditional bisphenol curable fluoroelastomer.

* Excellent flow ability and mold release.

* High tensile strength and anti rearing performance.

* Rapid curing process.

* Excellent agent resistant performance.

* Good compressing set character.

| Polyamine curing | Bisphenol curing | Peroxide curing | |

| Curing agent | Diamine | Bisphenol | TAIC |

Application

● Fuel seal

● Fuel pipe

● Shaft seal

● Turbocharger tube

● Watch band

Datasheet

| FDF351 | FDF353 | FDF533 | FDP530 | FDL530 | |

| Fluorine content % | 70 | 70 | 70 | 68.5 | 65 |

| Density (g/cm3) | 1.9 | 1.9 | 1.9 | 1.85 | 1.82 |

| Mooney Viscosity (ML (1+10)121℃) | 70±10 | 40±10 | 45±15 | 50±10 | 40±20 |

| Tensile strength after post cure (Mpa) 24h, 230℃ | ≥18 | ≥25 | ≥25 | ≥20 | ≥20 |

| Elongation at break after post cure (%)24h, 230℃ | ≥230 | ≥240 | ≥240 | ≥250 | ≥240 |

| Compression set (%) 70h, 200℃ | ≤35 | ≤20 | ≤20 | ≤25 | ≤25 |

| Application | Extrusion fuel pipes, turbocharger tube | Watch bands etc | |||

How to choose fluoroelatomer?

FKM Copolymer vs FKM Terpolymer

Copolymer: 66% fluorine content, general application, resistance to oil, fuel, heat, chemicals. Common application is o rings, oil seals, packers, gaskets, etc.

Terpolymer: higher fluorine content than copolymer 68% fluorine content. Better resistance to oil, fuel, heat, chemicals, used in harsh environment which copolymer can’t satisfy the requirements.

Bisphenol curable FPM vs Peroxide curable FPM

Bisphenol curable FPM has low compression set, offer used for o-rings, shaft seals, piston seals. Price is good.

Peroxide curable FPM has better resistance to polar solvents, steam, acids, chemicals. Price is much higher. Its often used for wearable devices, extrusion fuel hoses.

Storage

Viton precompound should be stored in a cool, dry and ventilated place. Shelf life is 24 months since production date.

Package

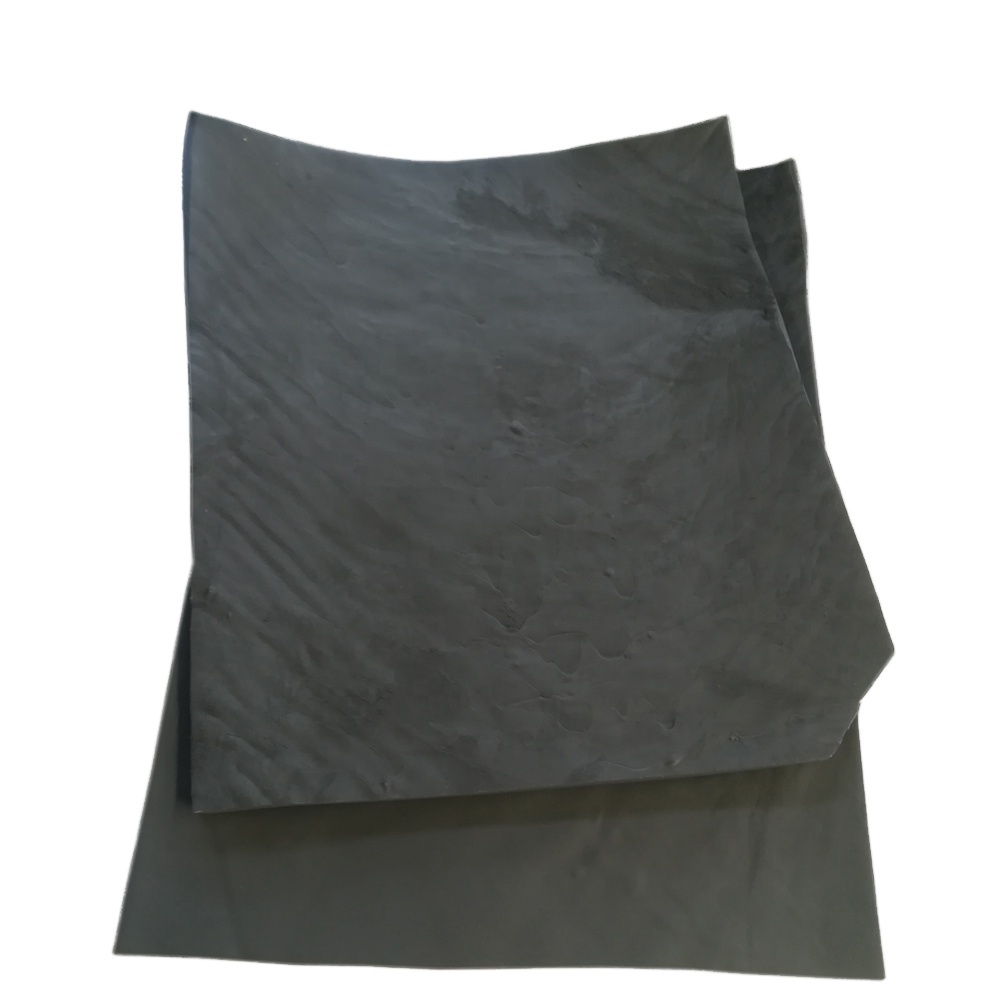

1. To prevent the compounds stick to each other, we apply PE film between each layer of FKM compounds.

2. Every 5kgs in a transparent PE bag.

3. Every 20kgs/ 25kgs in a carton.

4. 500kgs on a pallet, with strips to reinforce.

Product detail pictures:

Related Product Guide:

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for Factory Free sample Oring Ffkm - Peroxide Curable FKM Raw Polymer – FUDI , The product will supply to all over the world, such as: Borussia Dortmund, Angola, Kuwait, We hope to have long-term cooperation relationships with our clients. If you are interested in any of our products, please do not hesitate to send enquiry to us/company name. We ensure that you can be totally satisfied with our best solutions!

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!