Factory wholesale Fkm Gasket - General Purpose Fluoroelastomer Base Polymer – FUDI

Stock Sample is Free & Available

Factory wholesale Fkm Gasket - General Purpose Fluoroelastomer Base Polymer – FUDI Detail:

Viton FKM raw gum is raw material of viton rubber. We supply Chinese best quality of Viton FKM raw gum including Low Mooney, Middle Mooney and high Mooney grades.

FD26 serial FKM raw gum is one kind of copolymer composed of vinylidene fluoride (VDF) and hexafluoropropylene (HFP). It’s a standard type of FKM showing a good overall performance. You may find general properties of the material in below table.

|

Items |

Grades |

||||

| FD2601 | FD2602 | FD2603 | FD2604 | FD2605 | |

| Density (g/cm3) | 1.82±0.02 | 1.82±0.02 | 1.82±0.02 | 1.82±0.02 | 1.82±0.02 |

| Fluorine content (%) | 66 | 66 | 66 | 66 | 66 |

| Mooney Viscosity (ML (1+10)121℃) | 25 | 40~45 | 60~70 | >100 | 150 |

| Tensile strength after post cure (Mpa) 24h, 230℃ | ≥11 | ≥11 | ≥11 | ≥13 | ≥13 |

| Elongation at break after post cure (%)24h, 230℃ | ≥180 | ≥150 | ≥150 | ≥150 | ≥150 |

| Compression set (%) 70h, 200℃ |

≤25 |

||||

FD24 serial FKM raw gum is one kind of terpolymer composed of vinylidene fluoride (VDF), hexafluoropropylene (HFP) and tetrafluoroethylene (TFE). Terpolymers have a higher fluorine content compare to copolymers (typically between 68 and 69 weight percent fluorine), which

results in better chemical and heat resistance. You may find general properties of the material in below table.

| FD2462 | FD2463 | FD2465 | FD2465L | FD2465H | |

| Fluorine Content | 68.5 | 68.5 | 68.5 | 65 | 69.5 |

| Density (g/cm3) | 1.85 | 1.85 | 1.85 | 1.81 | 1.88 |

| Mooney Viscosity (ML (1+10)121℃) | 70±10 | 40±10 | 45±15 | 50±10 | 40±20 |

| Tensile strength after post cure (Mpa) 24h, 230℃ | ≥11 | ≥11 | ≥11 | ≥11 | ≥11 |

| Elongation at break after post cure (%)24h, 230℃ | ≥180 | ≥180 | ≥180 | ≥180 | ≥180 |

| Compression set (%) 200℃ 70H compress 20% | ≤30% | ≤30% | ≤30% | ≤30% | ≤40% |

| Oil resistance (200℃ 24H) RP-3 oil | ≤5% | ≤5% | ≤5% | ≤5% | ≤2% |

| Glass transition temperature (TG) | >-15℃ | >-15℃ | >-15℃ | >-21℃ | >-13℃ |

| Water content (%) | ≤0.15 | ≤0.15 | ≤0.15 | ≤0.15 | ≤0.15 |

Package and Storage

Fluoroelastomer are first sealed in PE bag-weights 5kgs per bag, then put into carton box. Net weight per box: 25kgs

Fluoreolastomer should be stored in a cool, dry and ventilated place. Shelf life is 24 months since production date.

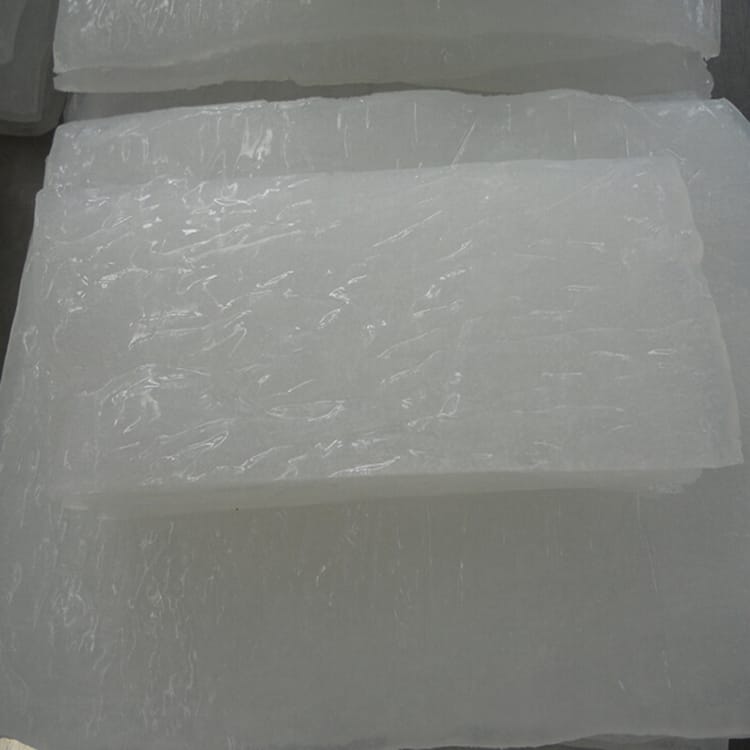

Product detail pictures:

Related Product Guide:

Our personnel are generally within the spirit of "continuous improvement and excellence", and using the excellent top quality goods, favorable rate and superior after-sales expert services, we try to win every customer's believe in for Factory wholesale Fkm Gasket - General Purpose Fluoroelastomer Base Polymer – FUDI , The product will supply to all over the world, such as: Rio de Janeiro, Cancun, Johor, We have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to contact us for more details.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!