Reasonable price Fkm Seal Material - Great Chemical Resistance Perfluoroelastomer Compound – FUDI

Stock Sample is Free & Available

Reasonable price Fkm Seal Material - Great Chemical Resistance Perfluoroelastomer Compound – FUDI Detail:

FUDI supply three types of perfluoroelastomer ffkm compound & ffkm polymer.

A. It has the broadest working temperature range and wide resistance to chemical media.

Features

● Outstanding resistance to high temperature up to 300-320℃

● Outstanding resistance to aggressive chemicals;

● Outstanding steam resistance;

● Outstanding compression set even at very high temperatures;

● Processability by standard fluoroelastomer technology on convential rubber equipments.

● Price is the most expensive.

Application

O-rings, seals, diaphragms and other parts used in process industries.

MOQ

300grams

Datas for reference

| Thermal resistance | |

| Heat aging 70 h @ 280℃ | |

| 100% Modulus Mpa | 9.5 |

| Tensile strength Mpa | 19.5 |

| Elongation at break % | 215 |

| Hardness Shore A | 72 |

| Heat aging 70 h @ 300℃ | |

| 100% Modulus Mpa | 7.5 |

| Tensile strength Mpa | 17 |

| Elongation at break % | 260 |

| Hardness Shore A | 72 |

| Heat aging 70 h @ 316℃ | |

| 100% Modulus Mpa | 6.5 |

| Tensile strength Mpa | 14 |

| Elongation at break % | 320 |

| Hardness Shore A | 72 |

B. It has limited working temperature range and widest resistance to chemical media.

Features

● Outstanding resistance to high temperature up to 250~260℃

● Outstanding resistance to aggressive chemicals;

● Outstanding steam resistance;

● Outstanding compression set even at very high temperatures;

● Price is cheaper than grade A.

Application

O-rings, seals, diaphragms and other parts used in harsh environment.

MOQ

300grams

Datas for reference

| Hardness Shore A | 74 |

| Gravity / | 1.99 |

| Tensile strength Mpa | 24.5 |

| 100% Modulus Mpa | 7.5 |

| Elongation % | 200 |

| Compression set 72 h @ 200℃ | 18.1 |

| Compression set 72 h @ 230℃ | 26.7 |

Chemical resistance (For Ketone, Ester, Ether)

| Chemical | Temp | Change after 168hr (%) | Change after 500hr (%) |

| Acetone | 40℃ | 2.5 | 3.3 |

| Methyl ethyl ketone | 2.2 | 3.2 | |

| Isophorone | 0.1 | 0.5 | |

| Ethyl acetate | 3.1 | 3.8 | |

| Dioxane | 1.2 | 2.0 | |

| Methyl isobuthyl ketone | 1.2 | 2.0 | |

| Acetylacetone | 0.8 | 1.3 | |

| Buthyl acetate | 1.5 | 2.5 | |

| Diethyl ether | 25℃ | 2.6 | 4.3 |

C. It has limited working temperature range and good resistance to chemical media.

Features

● Outstanding resistance to high temperature up to 240℃

● Outstanding resistance to aggressive chemicals;

● Outstanding steam resistance;

● Outstanding compression set even at very high temperatures;

● Processability by standard fluoroelastomer technology on conventional rubber equipments.

● Price is cheapest.

Datas for reference

| Hot air aging | 300℃×24Hrs | GB/T 3512-2014 | |||

| Tensile strength | % | -18.1 | |||

| Elongation | % | 17.1 | |||

| Hardness change | 0.2 | ||||

| Compression set | 23℃×70Hrs | GB/T 7759.1-2015 | |||

| Compression set | % | 11.2 | |||

| Compression set | 204℃×70Hrs | GB/T 7759.1-2015 | |||

| Compression set | % | 22.7 | |||

| Compression set | 250℃×70Hrs | GB/T 7759.1-2015 | |||

| Compression set | % | 33.2 | (There’re cracks) | ||

| Fule RP-3 | 150℃×24Hrs | GB/T 1690-2010 | |||

| Tensile strength | % | -14.3 | |||

| Elongation | % | 5.8 | |||

| Hardness change | -2 | ||||

| Volume change | % | 4.6 | |||

| Low temperature | GB/T 15256-2014 | ||||

| Brittle temperature | ℃ | -30 |

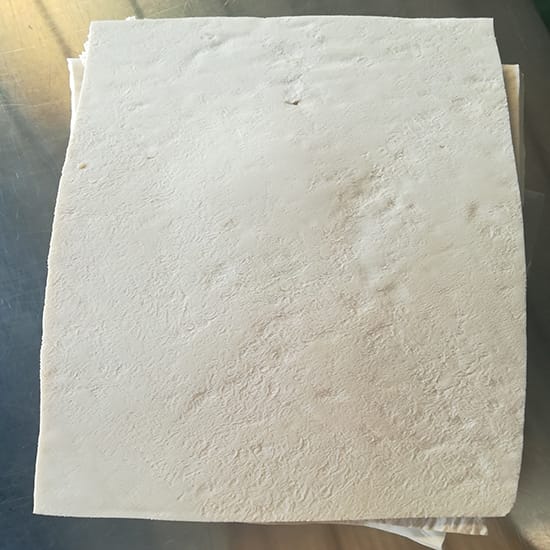

Product detail pictures:

Related Product Guide:

abide by the contract", conforms on the market requirement, joins within the market competition by its superior quality likewise as provides far more comprehensive and great company for shoppers to let them develop into huge winner. The pursue on the corporation, is definitely the clients' gratification for Reasonable price Fkm Seal Material - Great Chemical Resistance Perfluoroelastomer Compound – FUDI , The product will supply to all over the world, such as: Thailand, Canberra, India, We now have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we've been looking forward to even greater cooperation with overseas customers based on mutual benefits. You should feel free to contact us for more details.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.